Pure natural plant shoes and manufacturing method thereof

A natural plant, pure natural technology, applied in the field of pure natural plant shoes and their production, can solve the problems of wasting non-renewable resources, environmental pollution, endangering the living environment and health of human beings, etc., and achieves simple production, strong sweat absorption, and wear. soothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Embodiment: make 40 yards of hard sole slippers

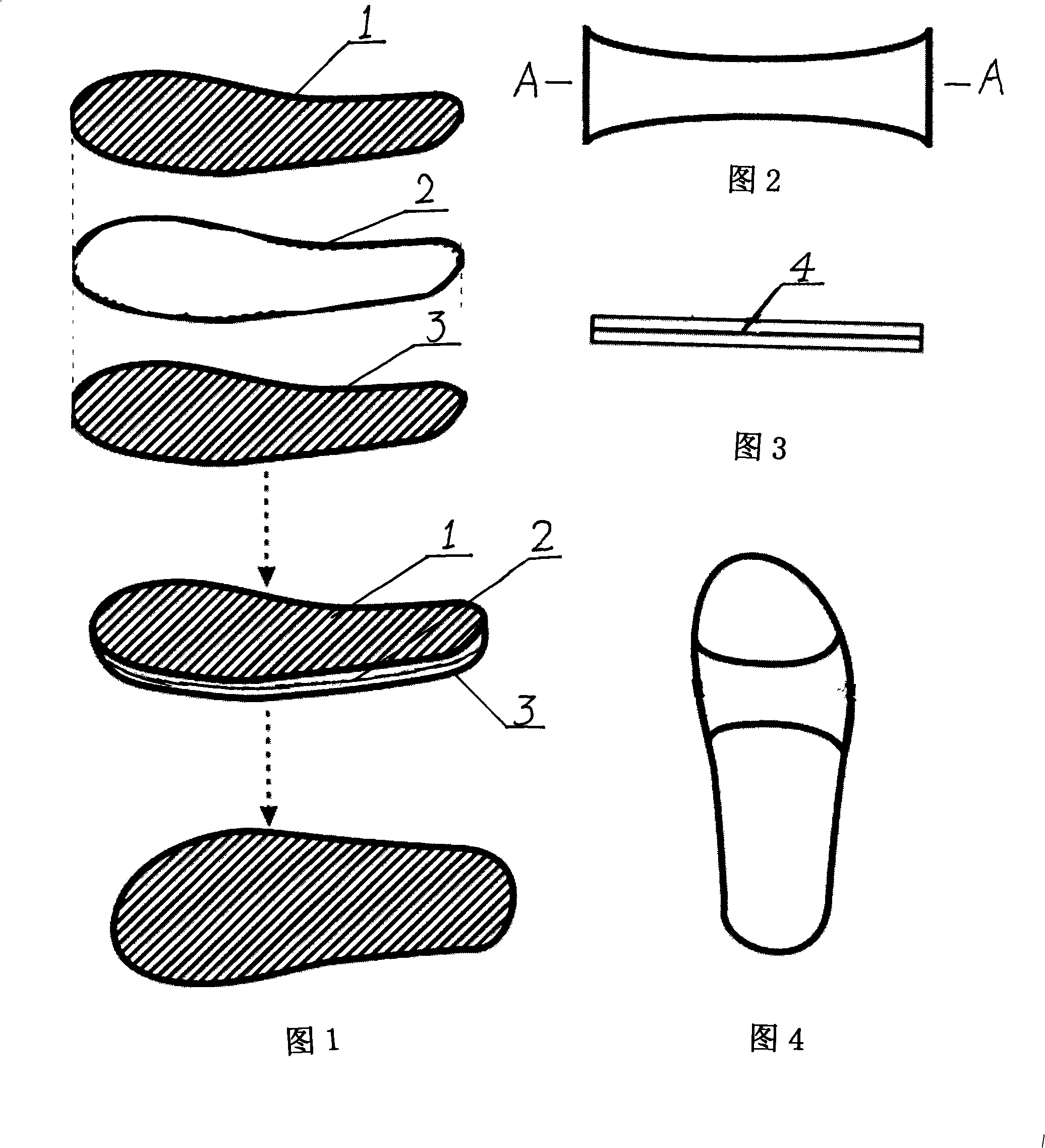

[0017] Referring to accompanying drawing, preparation method of the present invention is as follows:

[0018] 1. Selection of materials: Select appropriate amount of loofah, wooden planks (each plank is about 25cm long, 10cm wide, and 1.5cm thick), mountain palm, summer cloth, cotton thread, cotton cloth, hemp rope, and tung oil. Among them, the loofah is cut open, heart-dried, and then pressed into thin slices with a flattening machine to form loofah slices, which are set aside.

[0019] 2, make sole: (1) according to 40 yards of slipper sole molds (available in the market), planks are sawed into 40 yards of specifications, brushed with tung oil after polishing smooth with sandpaper, and dry. Tung oil must first be boiled with a slow fire until the temperature reaches 280-300 degrees Celsius. (2) According to the above-mentioned same shoe sole mold, the loofah slices are cut into the shape of an insole with a size of ...

Embodiment 2

[0023] Example 2: 40 yards of soft-soled slippers

[0024] 1. Raw materials and their processing:

[0025] Raw materials: appropriate amount of loofah, mountain palm, ramie rope, cotton rope, etc.;

[0026] Processing: Remove the heart of the loofah and press it into thin slices, cut it into 40 yards of insole shape with a cutting machine; dry the mountain palm, set aside, pour the water into the cold pot according to the ratio of 1 part of flour to 6 parts of water In the middle, mix in the flour, stir well so that the flour does not form a lump, and then simmer it into a batter. Take a flat plate, put the batter on the palm of the mountain, and paste it on the plate layer by layer, pay attention to the compaction and adhesion between the palm and the palm, and the thickness is even. After drying, peel off the whole mountain palm from the flat plate, and use a cutting machine to cut it into insole shapes with the same specifications as the loofah.

[0027] 2. Sole producti...

Embodiment 3

[0030] In this embodiment, loofah is used as sole surface layer 1, bottom layer 3 and vamp interlayer 4, and plank is used as sole middle layer 2. The preparation method and steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com