Taper degree mounting type off-centering machine cutting ferrule material drill

A technology of eccentricity and taper, which is applied in the directions of drilling repair, drilling tool accessories, transportation and packaging, etc. It can solve the problems of frequent replacement of oil-resistant rubber pads, inability of the guide keys to be close together, poor chip breaking, etc., and meet the requirements of ensuring product processing size, Reduce product roughness and improve cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

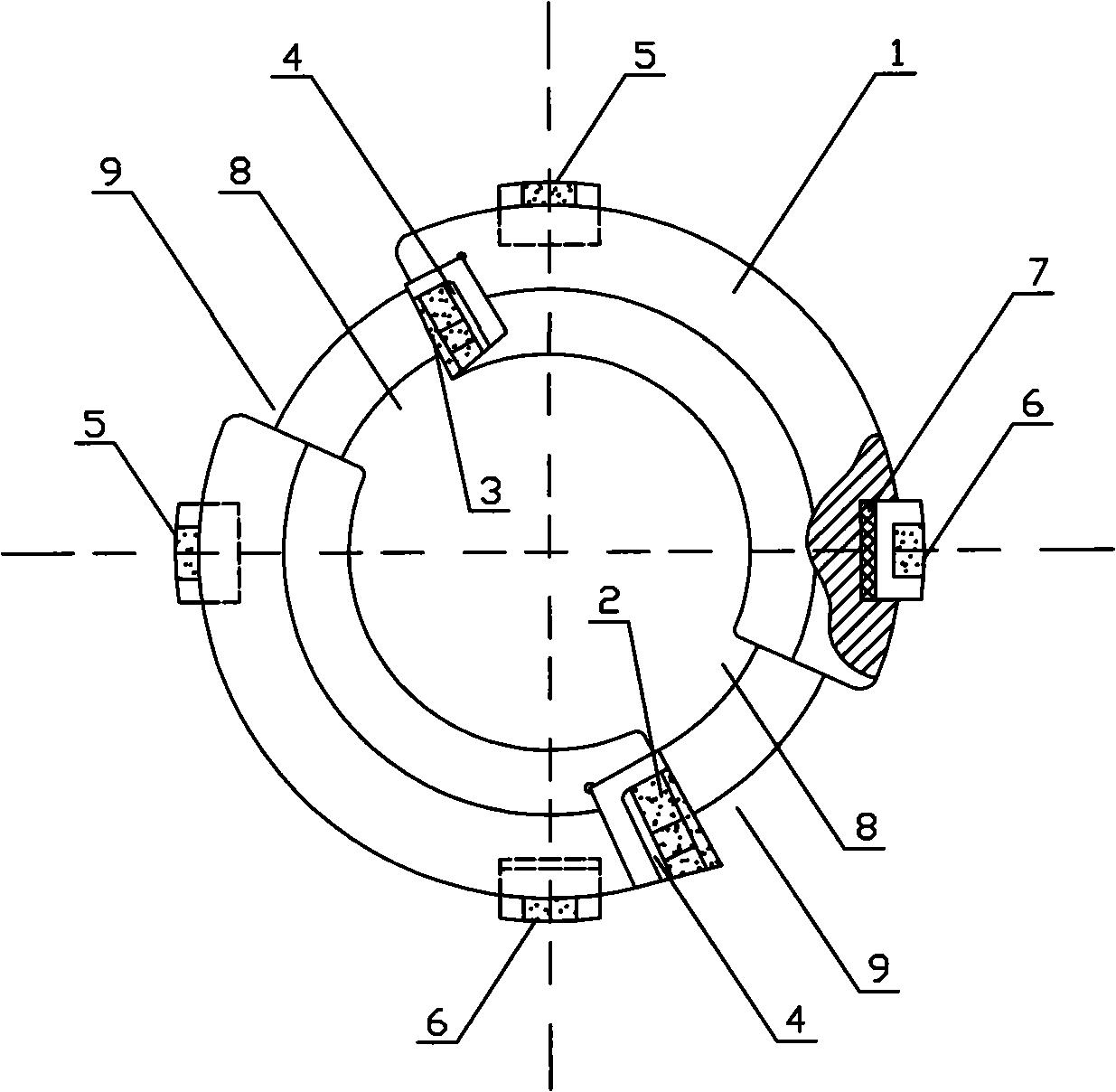

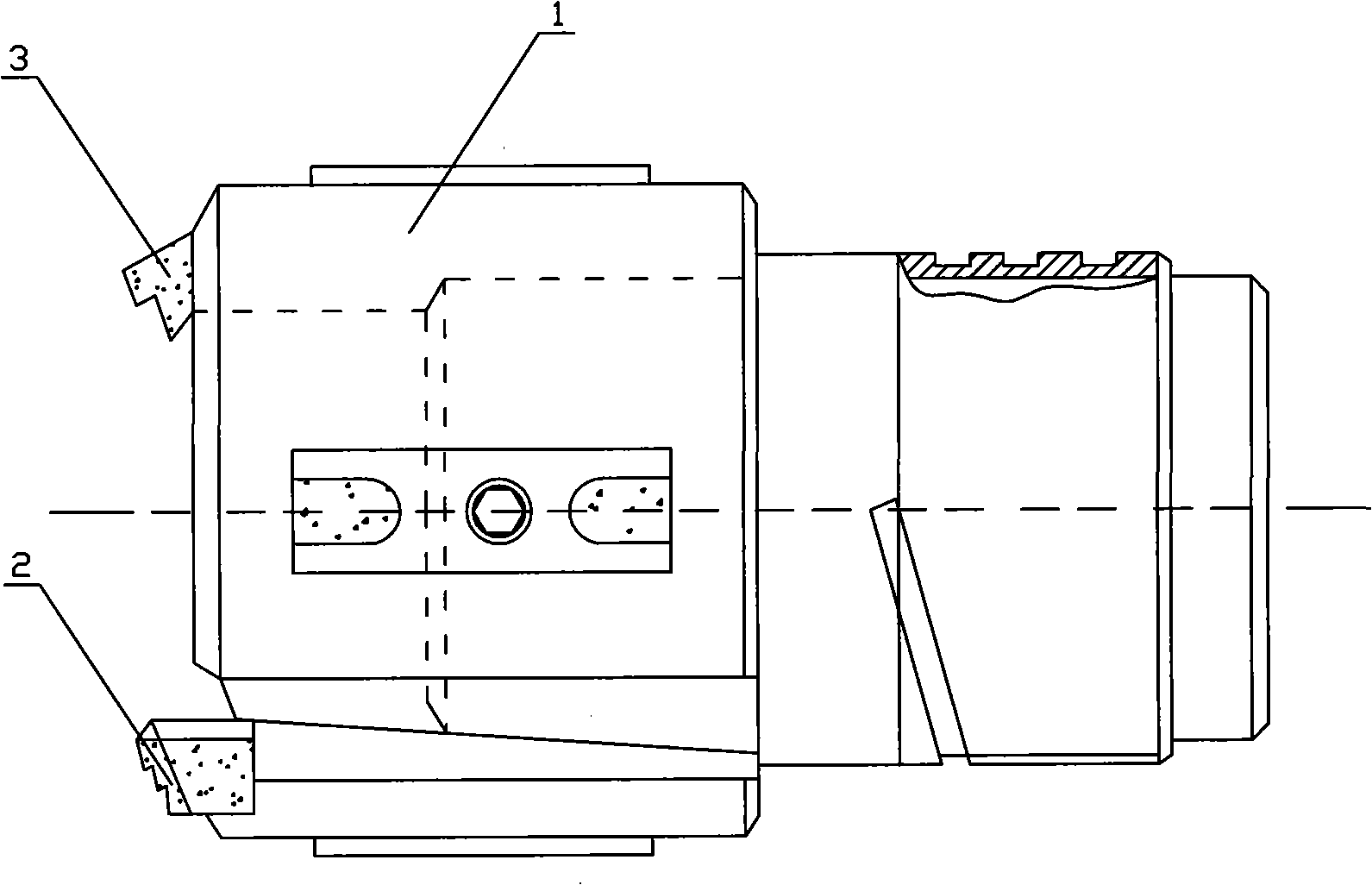

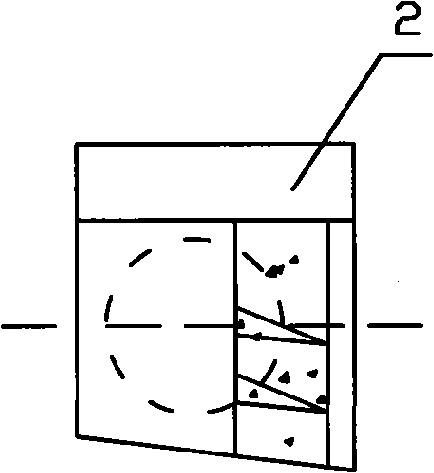

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown: a taper-mounted eccentric machine ferrule drill, including a cutter body 1, an outer cutter 2, an inner cutter 3, a cutter pad 4, two guide keys 5, two elastic keys 6, and two oil-resistant rubber pads 7 , two oil inlet gaps 8, two chip removal gaps 9, and machine card handles and machine card taper screws;

[0028] The two chip removal gaps 9 are each equipped with a dovetail-shaped eccentric machine card. The outer knife 2 and the inner knife 3 are respectively installed on the respective machine cards through the machine card taper screws. The dovetail-shaped eccentric machine card at the front of the handle;

[0029] In other embodiments, it may also be: the outer knife 2 and the inner knife 3 are respectively brazed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com