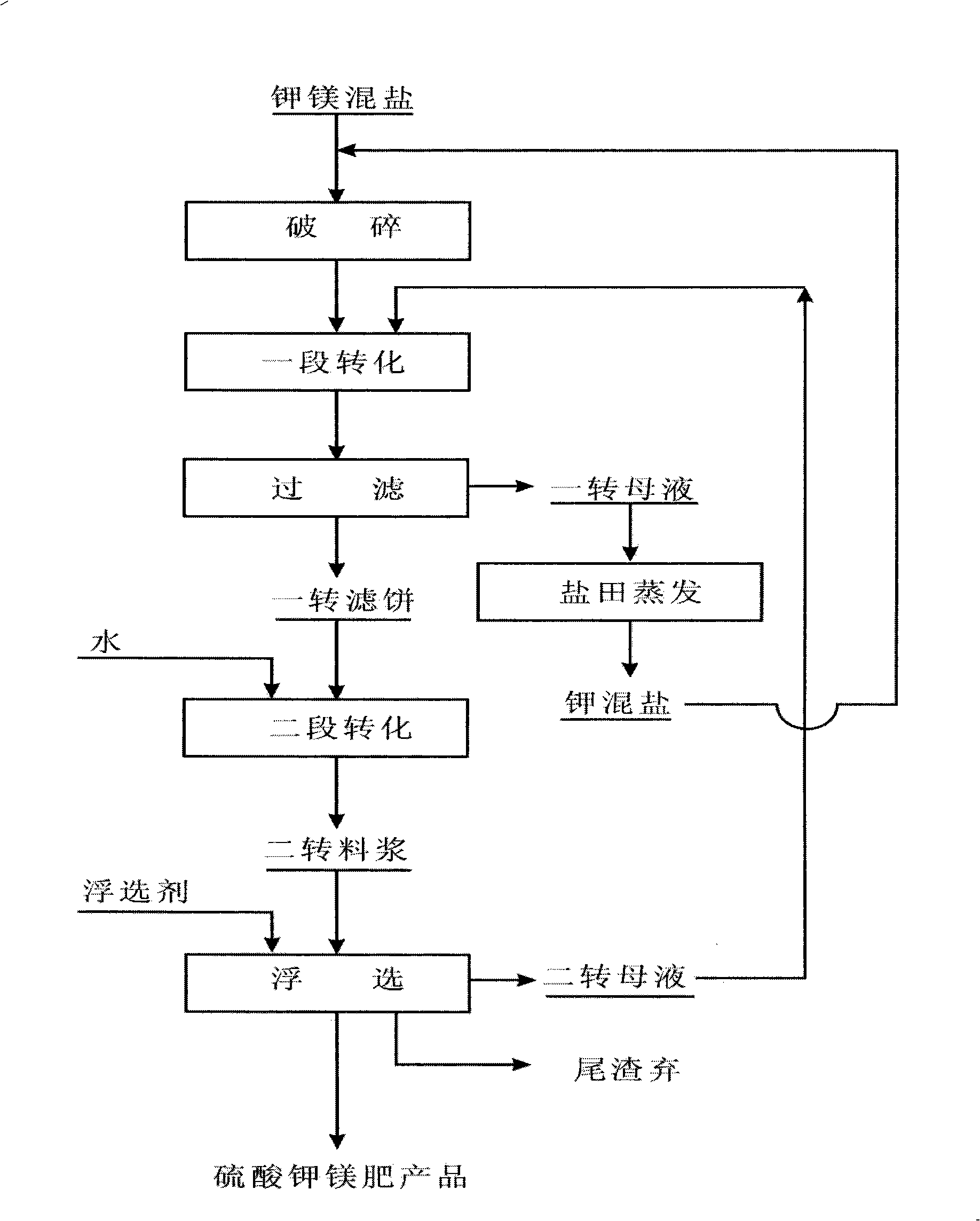

Process for preparing potassium magnesium sulfate fertilizer with two-stage conversion and floatation method

A technology of potassium and magnesium sulfate fertilizer and flotation method, which is applied in the field of salt chemical industry, which can solve the problems of high potassium content, high energy consumption, and low operation recovery rate, so as to reduce the loss of potassium element, shorten the process flow, and improve the recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

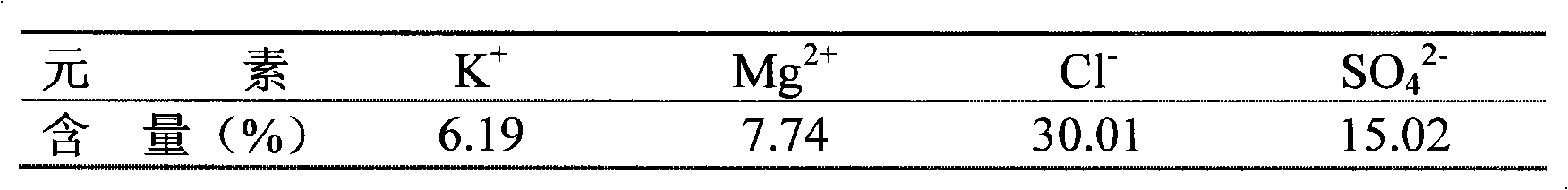

[0008] Embodiment 1 A kind of technique of two-stage conversion, flotation method producing potassium magnesium sulfate fertilizer, get 6000 grams of potassium magnesium mixed salt ore, crush to 1mm particle diameter, put into stirring reactor, press potassium magnesium mixed salt ore: two Transfer mother liquor = 1:0.4 ratio ingredients, stir and react at room temperature for 30 minutes, complete one-stage transformation, filter the first-stage transformation slurry to obtain 5300 grams of first-transfer filter cake and 4750 grams of first-transfer mother liquor, and return to salt field to evaporate the first-stage mother liquor to obtain Potassium-magnesium mixed salt ore is mixed according to the ratio of filter cake: water = 1:0.5, stirred and reacted at room temperature for 30 minutes, and the second-stage conversion is completed. The potassium-magnesium mixed salt ore: floating The ratio of agent selection=1t:150g is added to the flotation agent. The flotation agent is s...

Embodiment 2

[0009] Embodiment 2 A kind of technology of two-stage conversion, flotation method producing potassium magnesium sulfate fertilizer, get 6000 grams of potassium magnesium mixed salt ore, crush to 20mm particle diameter, put in stirring reactor, press potassium magnesium mixed salt ore: two Transfer to mother liquor = 1:1 ratio of ingredients, stir and react at room temperature for 120 minutes, complete one-stage transformation, filter the first-stage transformation slurry to obtain 5100 grams of first-transfer filter cake and 6800 grams of first-transfer mother liquor, and return to salt field to evaporate the first-stage mother liquor to obtain Potassium-magnesium mixed salt ore is mixed according to the ratio of filter cake: water = 1:0.2, stirred and reacted at room temperature for 60 minutes, and the second-stage conversion is completed. The potassium-magnesium mixed salt ore: floating The ratio of agent selection=1t:400g is added to the flotation agent. The flotation agent...

Embodiment 3

[0010] Embodiment 3 A kind of technology of two-stage conversion, flotation method to produce potassium magnesium sulfate fertilizer, get 6000 grams of potassium magnesium mixed salt ore, crush to 10mm particle diameter, put into stirring reactor, press potassium magnesium mixed salt ore: two Transfer mother liquor=1:0.8 ratio ingredients, stir and react at normal temperature for 90 minutes, complete one-stage conversion, filter the first-stage transformation slurry to obtain 5200 grams of first-transfer filter cake and 5,500 grams of first-transfer mother liquor, and return to salt field to evaporate the first-stage mother liquor to obtain Potassium-magnesium mixed salt ore, batching according to the ratio of filter cake: water = 1:0.35, stirred and reacted at room temperature for 45 minutes, and completed the second-stage conversion, and mixed potassium-magnesium salt raw ore: floating The ratio of agent selection=1t:200g is added to the flotation agent, the flotation agent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com