Pouring method for stove inner lining of aluminum solution holding stove

A technology for maintaining furnace and furnace lining, applied in the direction of lining repair, etc., can solve the problems of poor thermal insulation effect, difficult construction, long construction period, etc., and achieve the effect of good overall structure, simplified furnace construction process, and extended overhaul period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Describe in detail below in conjunction with embodiment.

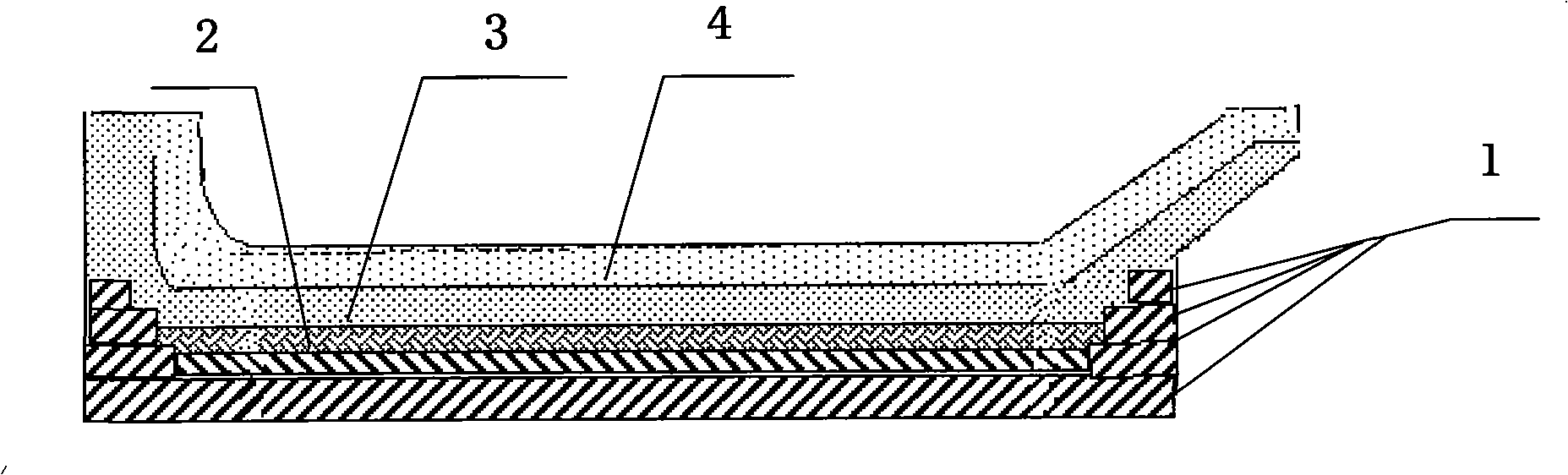

[0036] (1) Determination of the construction plan for maintaining the lining of the furnace

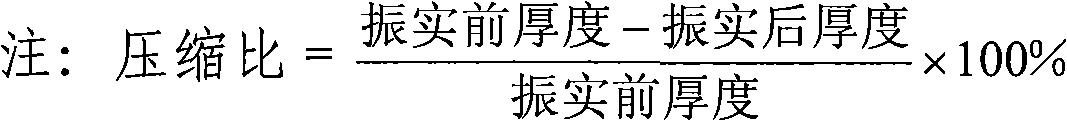

[0037] In order to maintain the capacity of the furnace, the total thickness of the furnace bottom lining is kept consistent with that before the transformation. The total thickness is 563mm, and the furnace bottom lining is constructed in 4 layers according to the material. The bottom layer is 120mm thick red brick. In order to more effectively insulate heat and prevent the infiltration of molten aluminum, a layer of BFS-II dry anti-seepage material with a thickness of 113mm is hammered on the second layer, that is, the upper part of the red brick, and the third layer is LBQ-0.8 light heat insulation Casting material, its thickness is 100mm. The uppermost layer, the fourth layer, is LBG-70 low-cement high-strength castable with a thickness of 230mm.

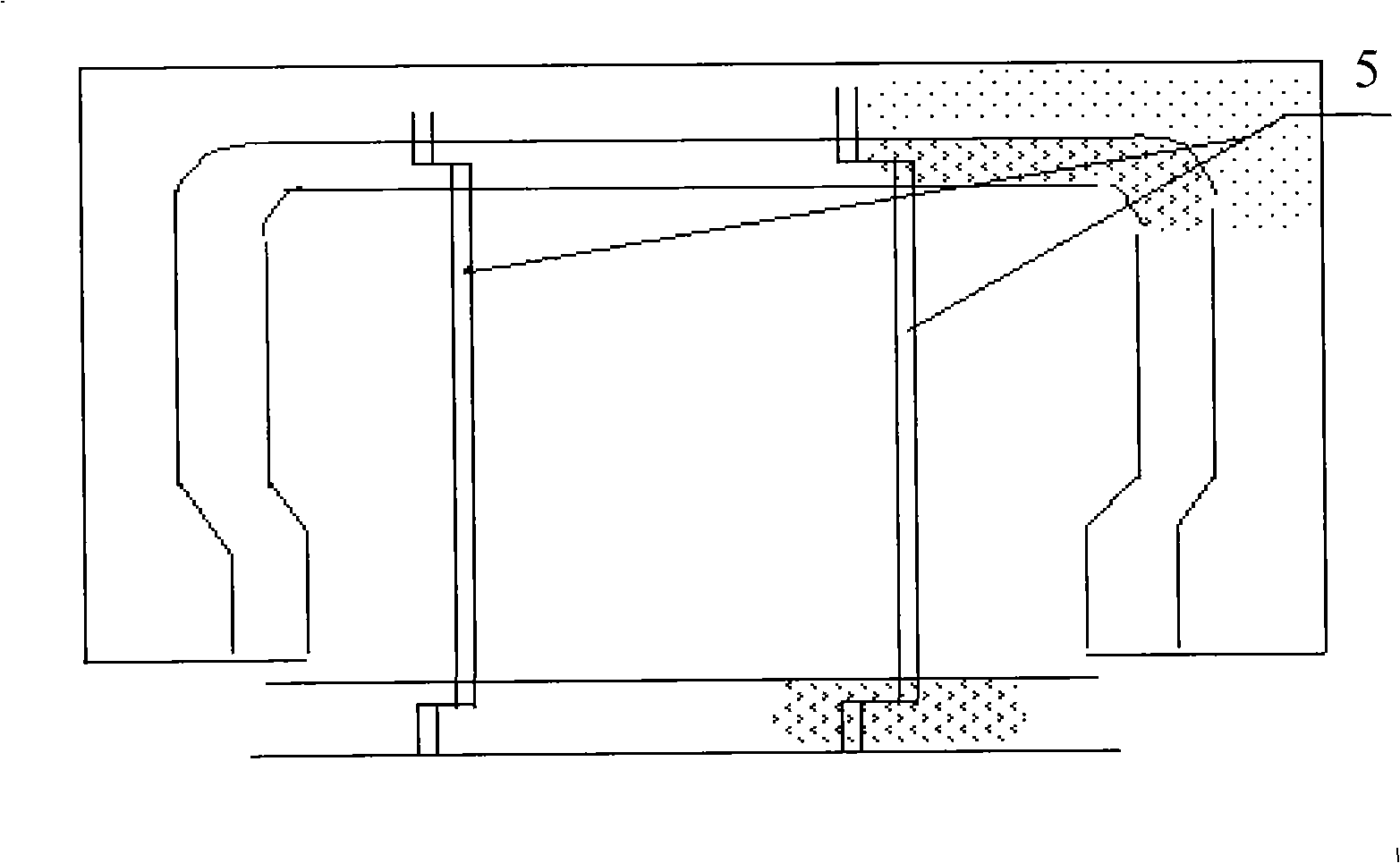

[0038] The lining of the maintenance furnace (containment pool) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com