Polyurethane elastomers comprising allophanate modified isocyanates

A technology of polyurethane elastomer and allophanate, applied in the field of polyurethane elastomer, can solve problems such as no working example

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

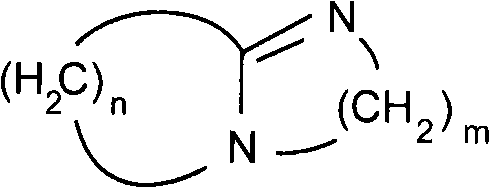

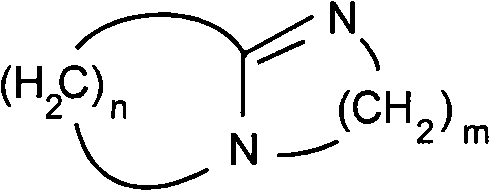

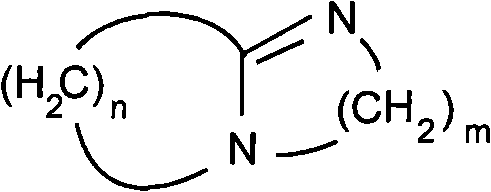

Image

Examples

Embodiment

[0087] Isocyanate A: An allophanate based on IPDI and isobutanol was prepared by mixing 15740 grams (142 equivalents) of IPDI with 971 grams (13 equivalents) of isobutanol. The resulting allophanate contained 30.55% NCO. A prepolymer of allophanate was prepared by mixing 16720 grams (103 equivalents) of the above allophanate with 1091 grams (4.3 equivalents) of trimethylolpropane. The NCO group content of the obtained prepolymer was 25.9% by weight.

[0088] Polyol A: Polyether polyol with a nominal functionality of about 3, a molecular weight of about 6000, an OH value of about 28, and a maximum unsaturation content of about 0.005 meq / g. The polyether polyol comprises the reaction product of glycerol and propylene oxide, contains about 20% EO capping, and is prepared in the presence of a double metal cyanide catalyst.

[0089] Polyol B: Crosslinking agent, functionality about 4, molecular weight about 350, OH value about 630, including propoxylated products of ethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com