Speed change control method for cam non-circular grinding based on constant contact arc length

A technology of contact arc length and control method, which is applied in the direction of abrasive belt grinder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

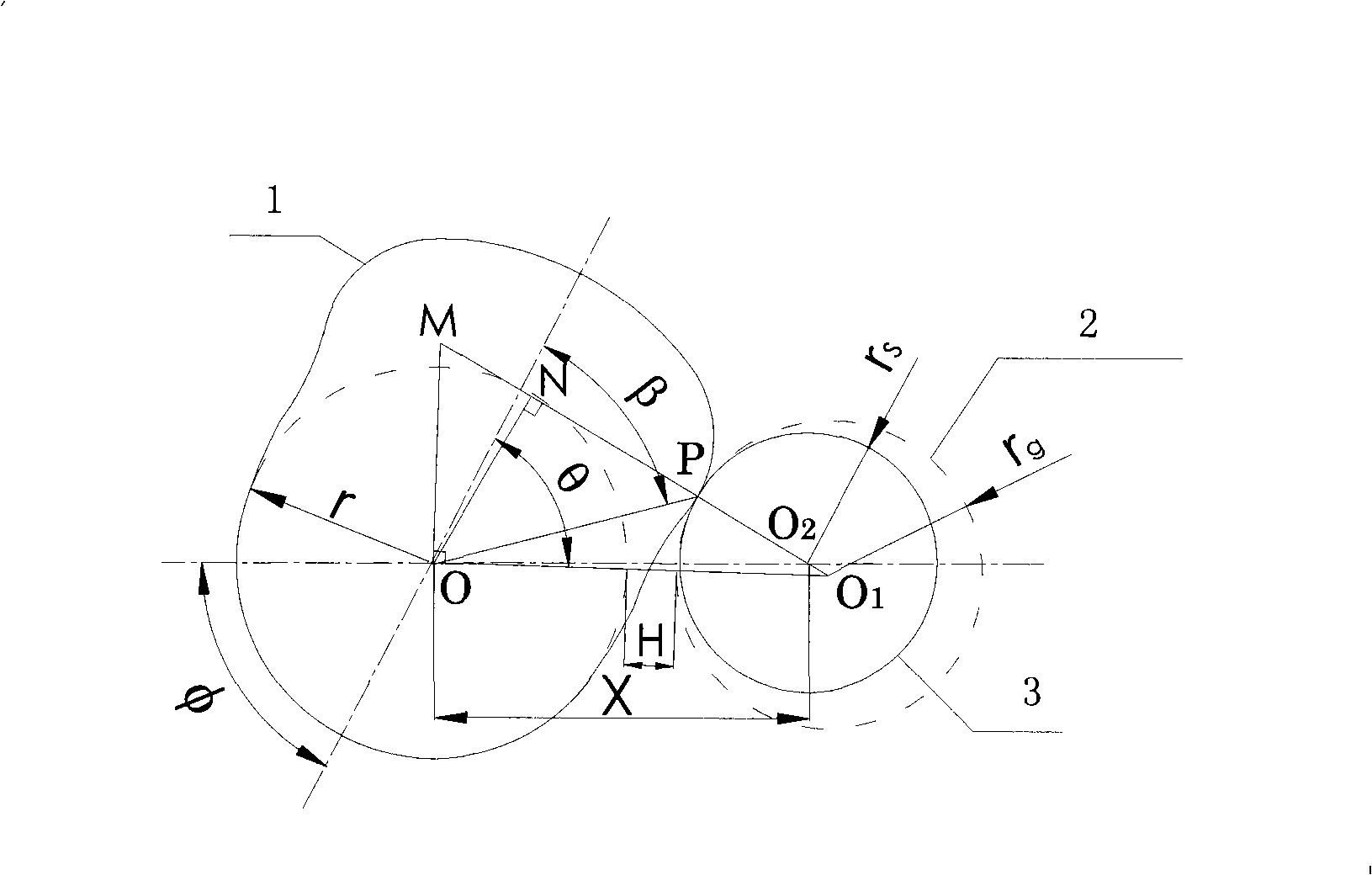

[0037] see figure 1 , label 1 among the figure is a cam, 2 is a tappet roller, and 3 is a grinding wheel. In this embodiment, the cam non-circular grinding technology is used to process a large concave-convex wheel. The specific implementation steps of the cam non-circular grinding based on the variable speed control method of constant contact arc length are as follows:

[0038] (1) Initialization parameters r, r g 、r S , θ, H, H(θ), ρ, V S 、a p , L

[0039] r is the base circle radius, r g is the roller radius, r S is the radius of the grinding wheel, θ is the center rotation angle of the roller, H is the lift value, H(θ) is the lift function, ρ is the radius of curvature, V S is the linear speed of the grinding wheel, a p is the grinding feed rate, and L is the contact arc length.

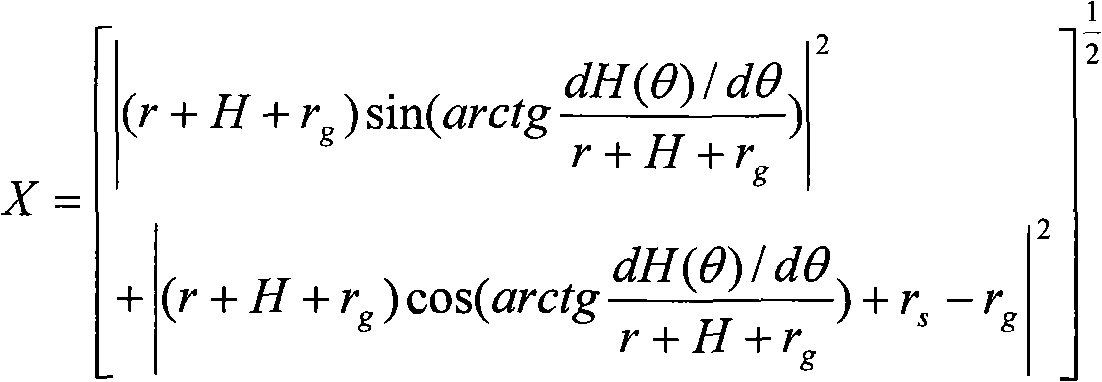

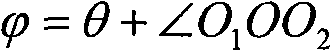

[0040] (2) Calculate the position X of the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com