Handhold rotating circular tray type automatic outside rendering machine

A rotating disk and disk-type technology, which is applied in the direction of construction and building construction, can solve the problems of poor mortar adhesion, falling, and complicated adjustment, and achieve the effect of smooth surface, light weight, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

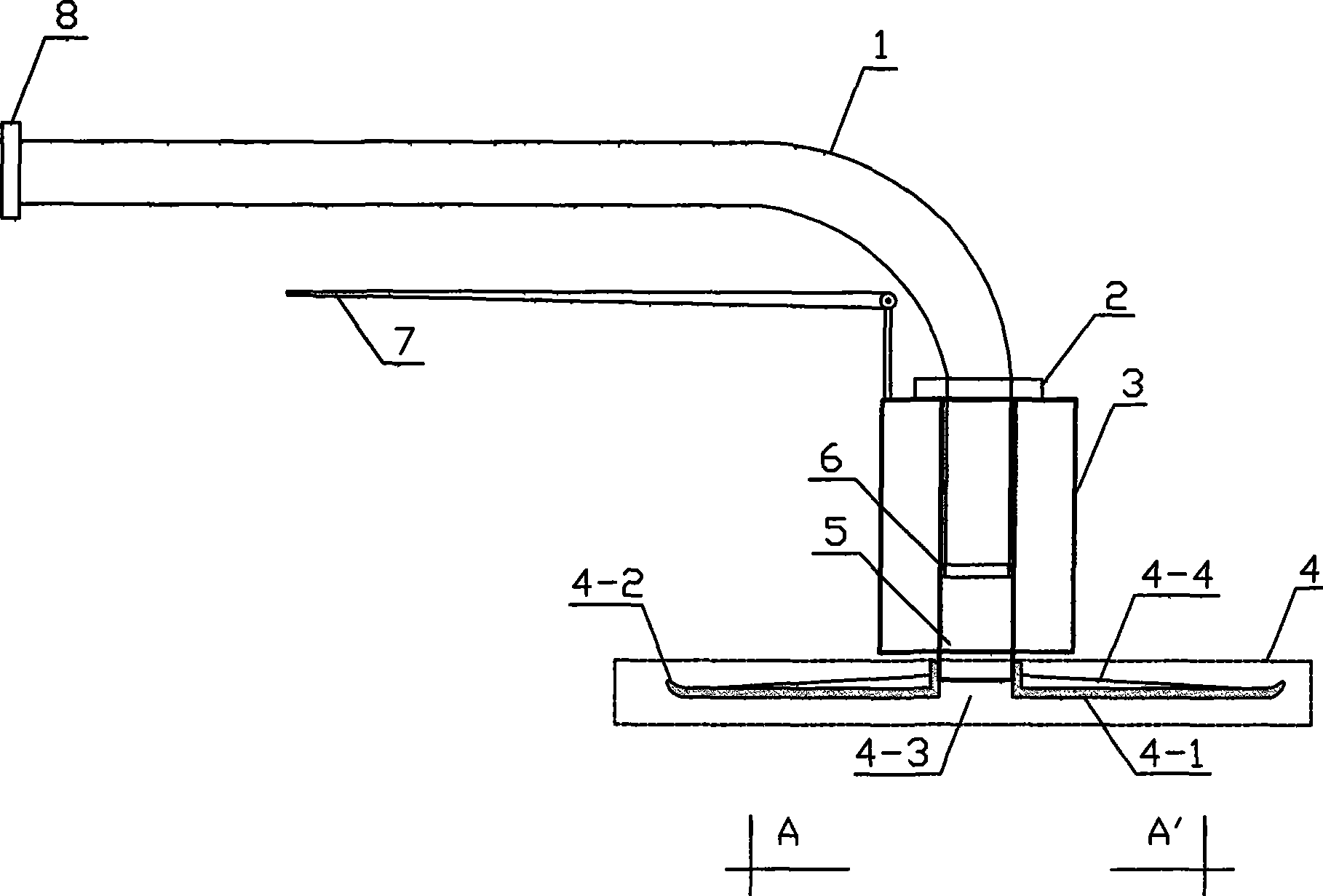

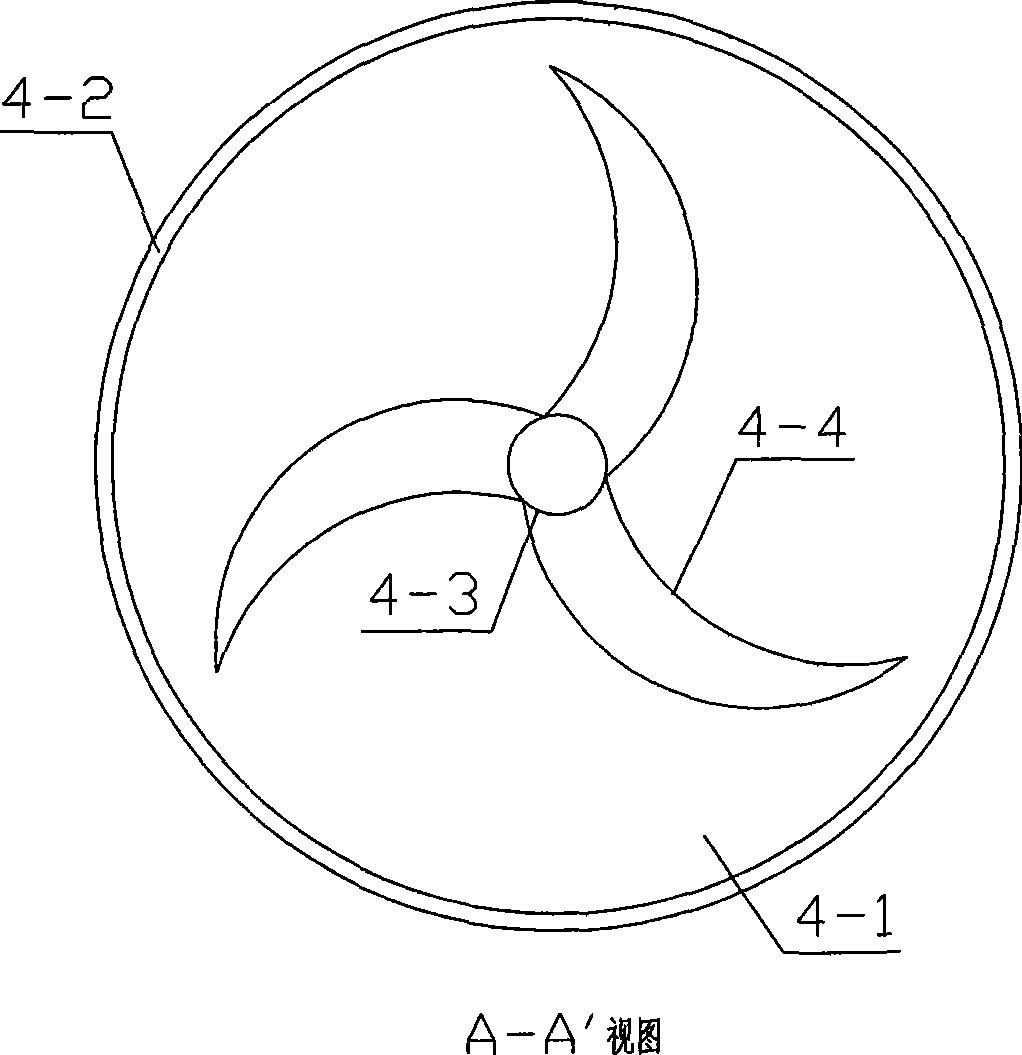

Embodiment 1

[0040] Embodiment 1: In actual use, such as image 3 As shown, the present invention can be used in conjunction with an automatic feeding system (automatic mortar conveying system), and the feeding pipe (1) is connected and fixed with the feeding pipe of the automatic feeding system. Connect the air source of the air motor (3), hold the control switch (7), the rotor of the air motor starts to rotate, drives the hollow shaft (5) to rotate synchronously, and drives the disc plastering board (4) to rotate; when the mortar is It is transported up by the automatic feeding system, passes through the feeding pipe (1), enters the hollow shaft (5) of the air motor (3), and then reaches the central hole (4-3) of the disc plastering board (4); When the external powder machine is pressed on the working surface that needs to be plastered, due to the pressure and the rotation of the disc, the mortar will enter the spiral guide groove (4-4) and be spread evenly, so as to realize the purpose ...

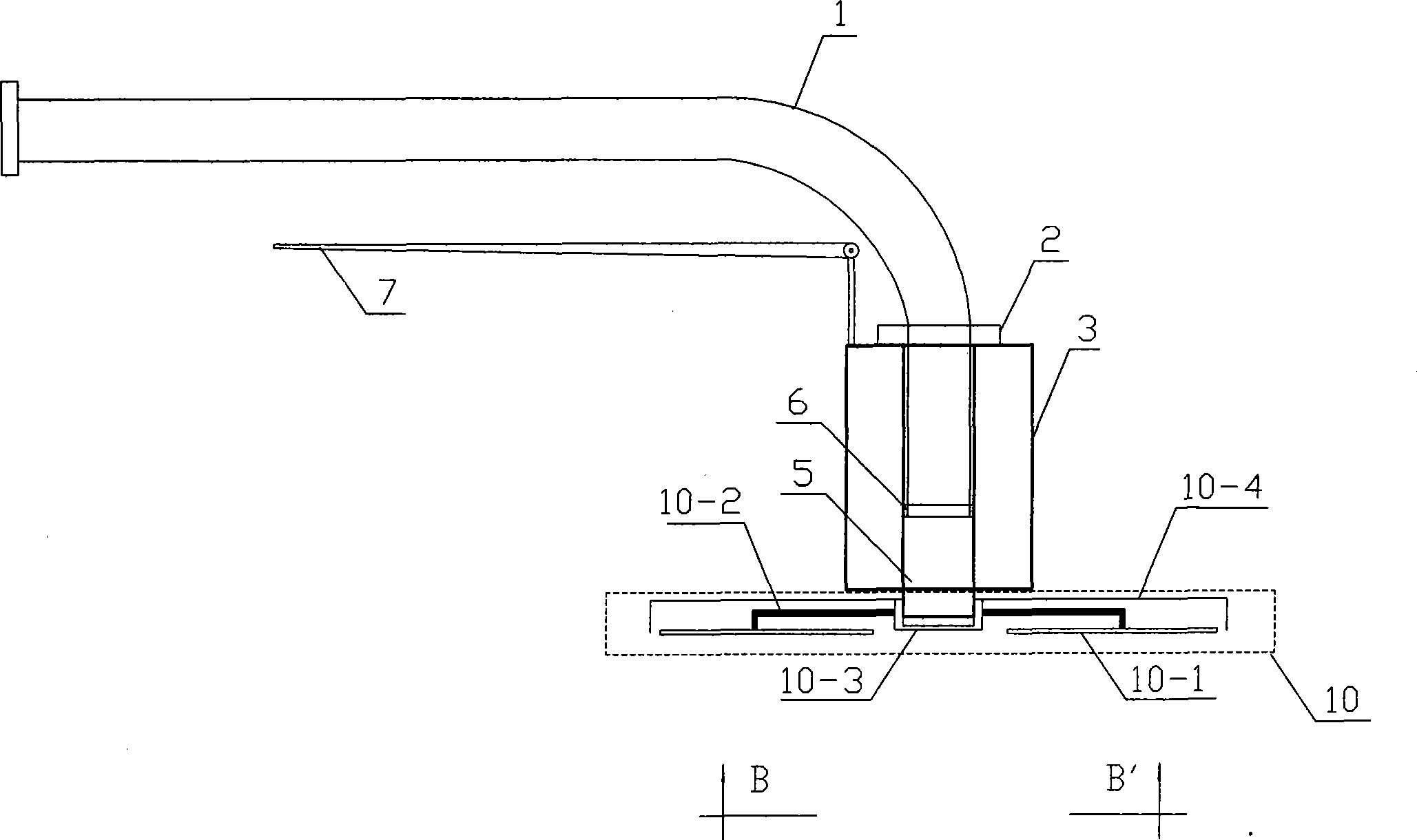

Embodiment 2

[0041] Embodiment 2: In actual use, after the present invention is installed with the rotary calendering plate (10), the calendering operation in the external powder can be carried out, and the central pipe no longer needs ash at this time. When the grip switch (7) is held down, the rotary calendering plate (10) rotates with the hollow shaft (5) of the air motor (3); when the rotary calendering plate (10) is pressed on the working surface, the pressing The rotation of the smoothing blade (10-1) forms a continuous smoothing operation on the working surface to achieve a calendering effect. Protective cover (10-4) plays a safety protection role.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap