Piston type multi-stroke connecting bar non-oscillating engine

A double-stroke, piston-type technology, applied in the field of piston-type engines, can solve the problems of complex crankshaft structure, difficult to guarantee machining accuracy and shape and position, and large engine crankcase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

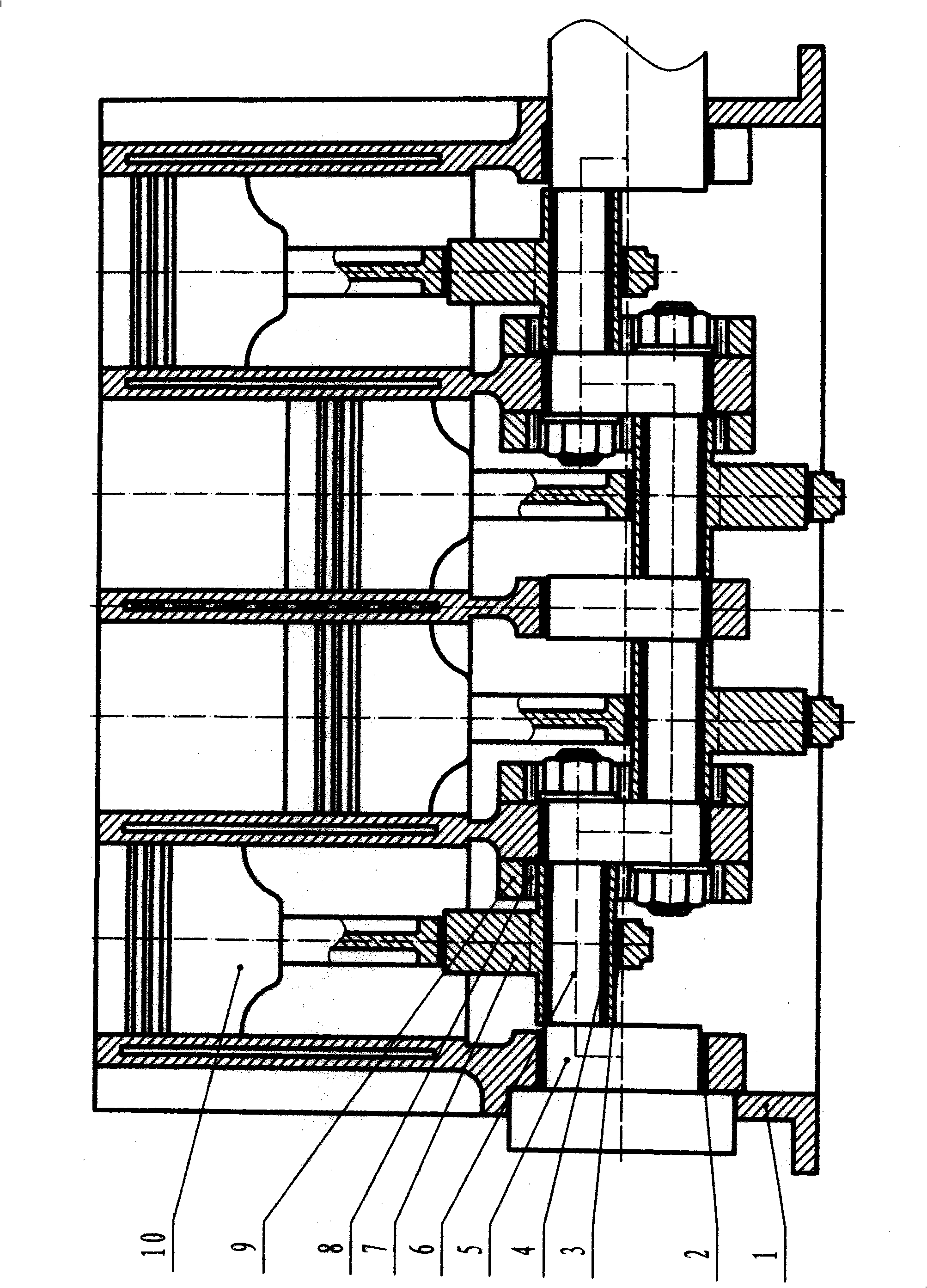

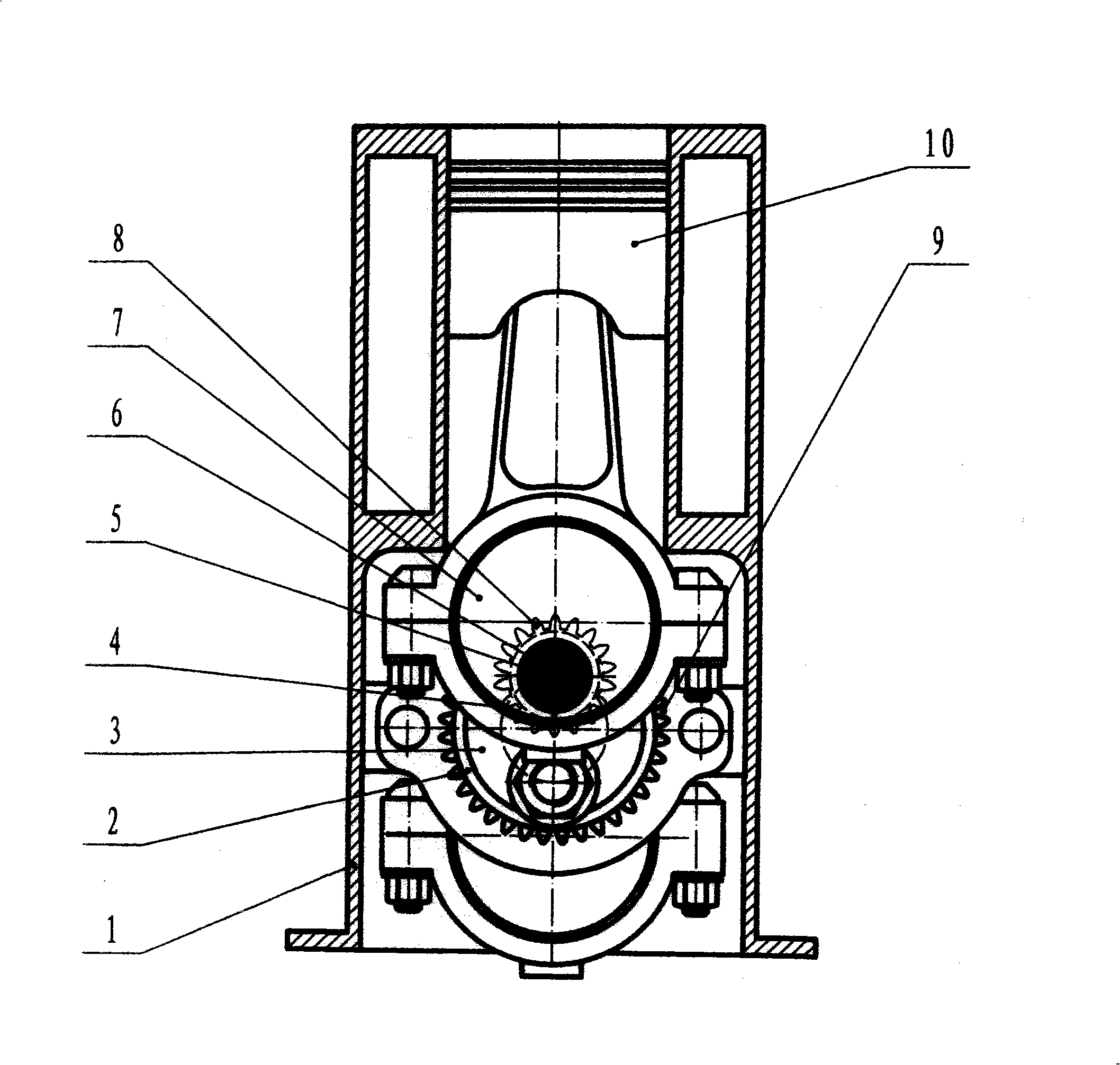

[0011] This four-cylinder piston-type double-stroke connecting rod of the present invention has an in-line arrangement without swing engine, has an organic base, and is fixedly arranged on the cylinder body (1), bearing, and internal gear of the base, and the cylinder body is equipped with a piston, and the piston The rear end is fixedly connected with a piston rod, and the inner gear is correspondingly meshed with a planetary gear (8). Piston rod and its axle sleeve that cooperates with eccentric wheel constitute piston-connecting rod assembly (10), and the crankshaft journal of crankshaft and its bearing and crankshaft constitutes crankshaft assembly (5). The crankshaft is integrated, which greatly simplifies the processing and installation process, and can ensure the overall row position tolerance and the smooth and reliable operation of the four-cylinder. The cylinder body (1) is located on the upper part of the base (crankcase), and the lower part of the base (crankcase) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com