Steel faucet prestress steel cylinder concrete thermal insulation pipe

A technology of reinforced concrete and prestressed steel wire, which is applied in the direction of heat preservation and heat insulation to protect pipes and pipes, etc., which can solve the problems of weak resistance to uneven settlement, the impact of anti-corrosion layer on the conveying medium, and increased manufacturing costs. Adverse effects, good water-tightness of joints, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

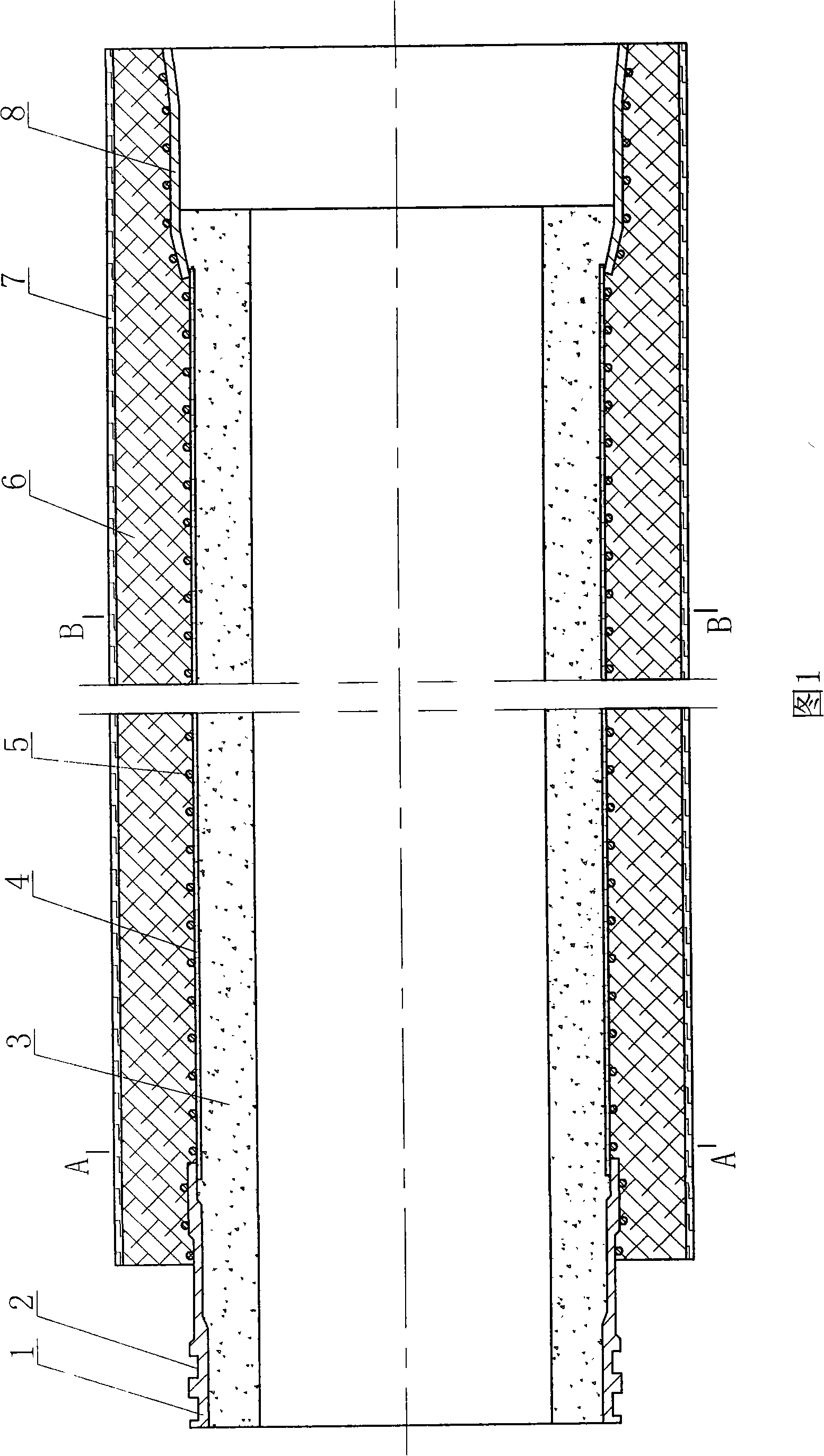

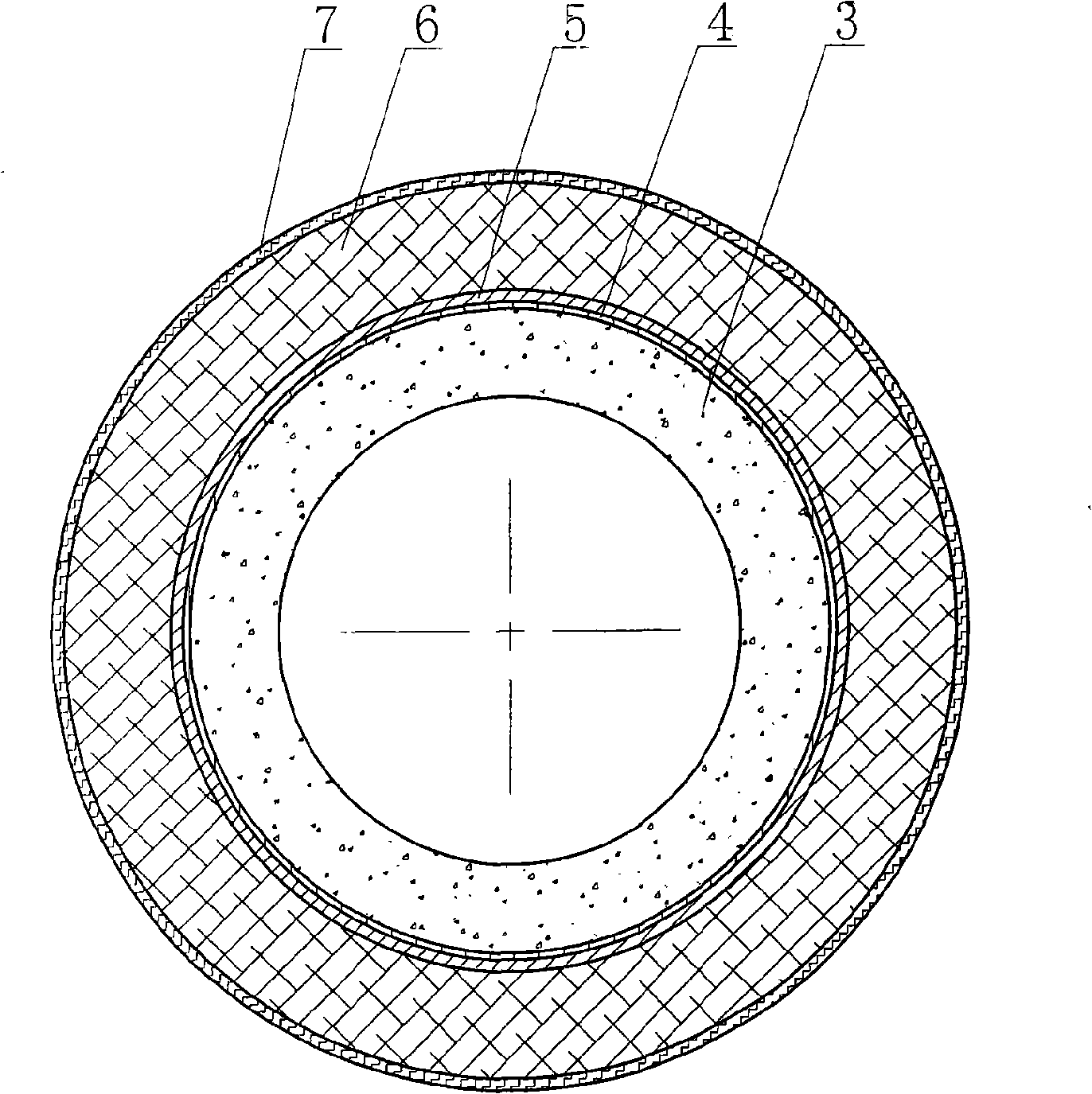

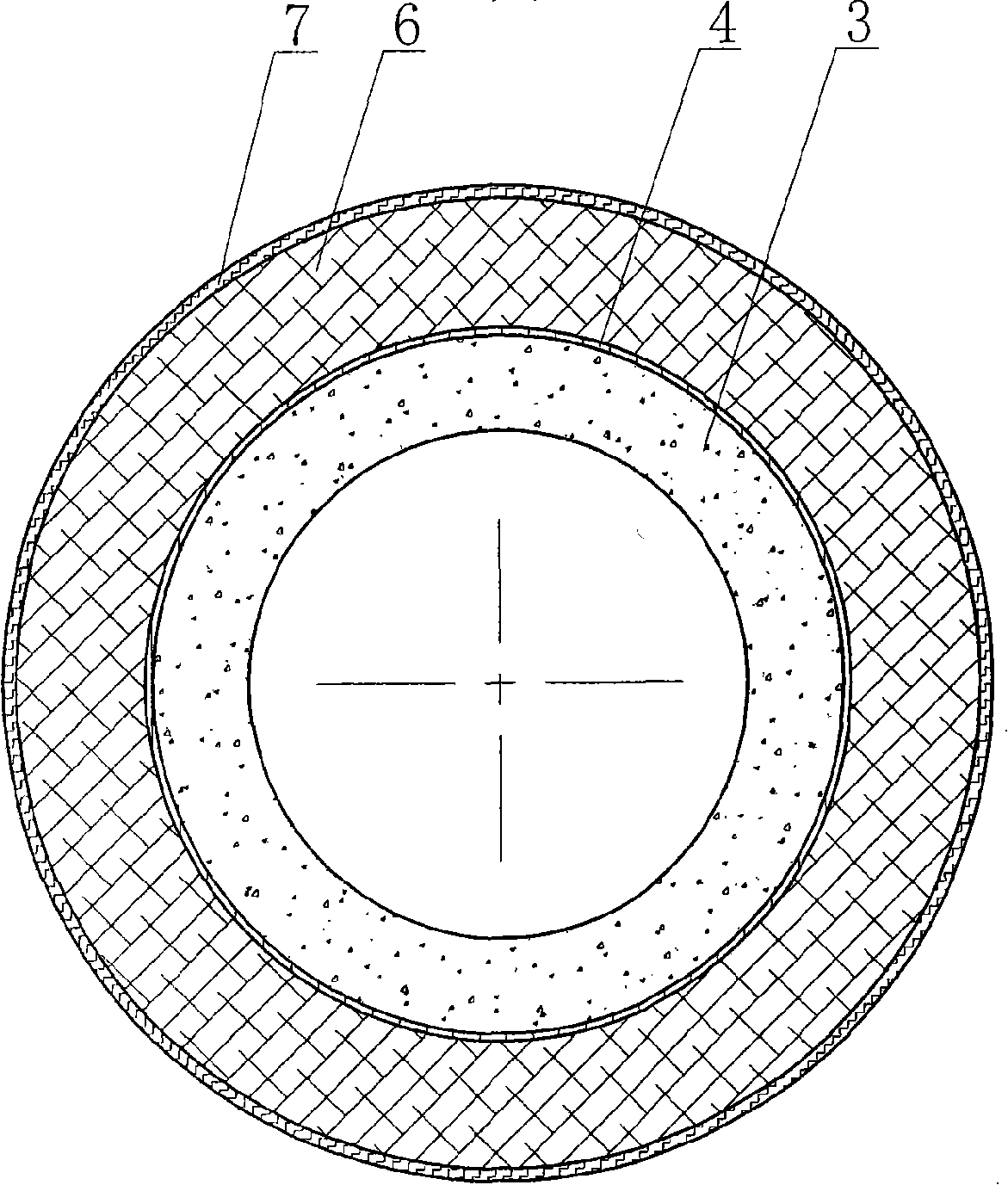

[0022] The steel socket prestressed steel cylinder concrete insulation pipe is composed of a tube core 3 and an insulation layer. The insulation layer is composed of polyurethane rigid foam 6 and high-density polyethylene 7 from inside to outside. The polyurethane rigid foam is made of The conventional process is foamed on the outer wall of the tube core, and the high-density polyethylene is wound on the outside of the polyurethane rigid foam layer. The pipe core is composed of a concrete pipe core and a steel cylinder 4. The steel cylinder is coaxially fixed on the outer wall of the concrete pipe core. A socket 1 and a socket 8 are respectively fixed at both ends of the pipe core. 1-3 grooves 2 (2 grooves are shown in the accompanying drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com