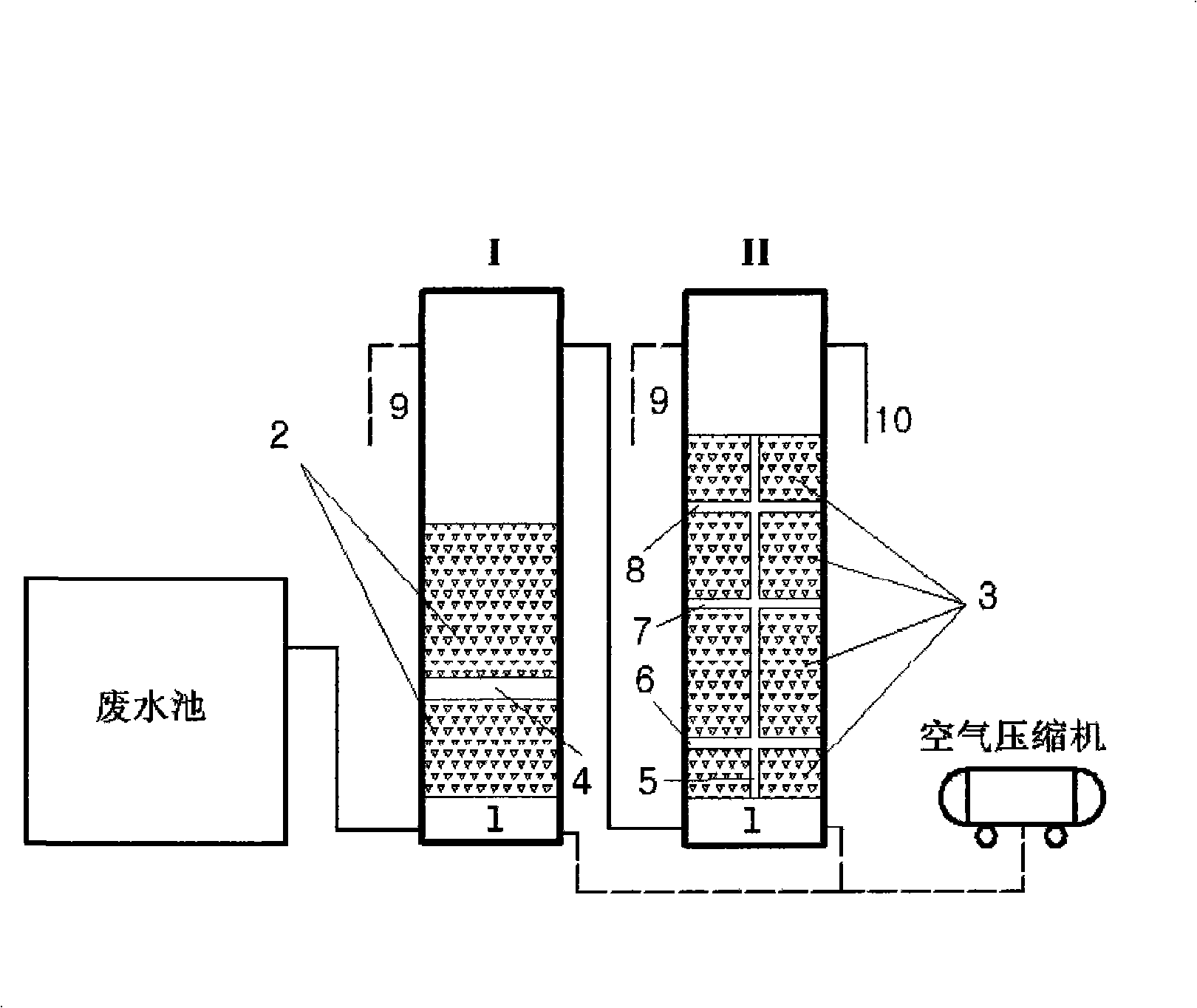

Tandem type two-stage three-segment aerating biological filter

An aerated biological filter, a series-type technology, is applied in the field of a series-type two-stage three-stage aerated biological filter, which can solve the problems of low contact efficiency between sewage and air, uneven wastewater treatment, secondary pollution, etc. Conducive to biofilm attachment, avoiding direct impact and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In a factory, a series-type two-stage three-stage biological aerated filter pilot plant was established, and the material was made of plexiglass. The inner diameter of the biological aerated filter is 50cm, the thickness is 5cm, and the overall height is 250cm; the height of the bottom support layer is 50cm, which is composed of homogeneous quartz sand with a particle size of 20cm; the height of the packing layer in the biological aerated filter I is 100cm, and the The filler layer in Pool II is 150cm high, and it is composed of porous and homogeneous volcanic rock particles with a particle size of 3-5cm. The bulk density of the volcanic rock particles is 750-780Kg / m 3 , The porosity is about 82%. In the aeration filter I, an aeration pipe with a diameter of 10 cm and 5 aeration holes with an inner diameter of 5 cm is set at a place 60 cm high from the supporting layer, and a stainless steel screen is built in it to prevent the filler from entering. In the aeration fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com