Polyester type polyurethane micropore elastomer added with low cost polycarbonate polyatomic alcohol and preparation thereof

A polyester polyurethane, microporous elastomer technology, applied in the application, shoe sole, clothing and other directions, can solve the problems of poor tensile strength and other physical properties, increase the cost of sole material, reduce the density and other problems, and achieve the reduction of raw material cost and improvement of physical properties. , the effect of reducing the molding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

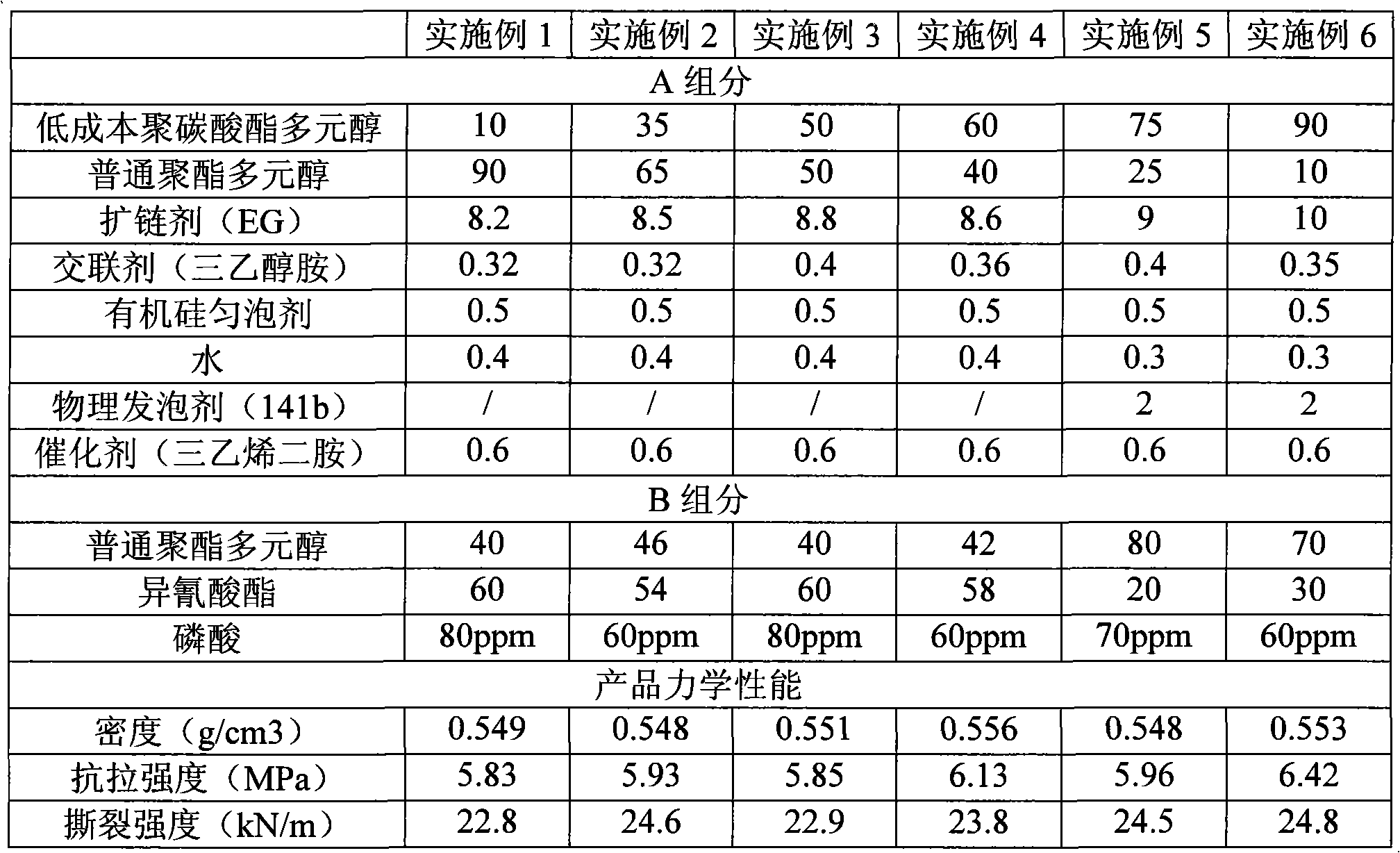

Examples

Embodiment 7

[0043]Embodiment 7: On the basis of Examples 1 to 6, the preparation method of polyester polyurethane microcellular elastomers with low-cost polycarbonate polyols added, (1) A component preparation: 10 to 90 parts by weight of Low-cost polycarbonate polyol, 90-10 parts by weight of ordinary polyester polyol, 5-30 parts by weight of small molecule diol chain extender, 0-10 parts by weight of cross-linking agent, 0.2-10 parts by weight Tertiary amine or organometallic catalyst, 0.2-2.5 parts by weight of organosilicon foam stabilizer, 0.01-5 parts by weight of water / physical foaming agent are placed in the reaction kettle, and fully mixed at 20-50°C for 2-4 hours Discharge, sealed and stored, to obtain component A; (2) Preparation of component B: put 40-80 parts by weight of isocyanate, 60-20 parts by weight of ordinary polyester polyol, and 10-200 ppm of side reaction inhibitor In the reaction kettle, react at 60-80°C for 2-3 hours, remove air bubbles in a vacuum, cool down to ...

Embodiment 8

[0048] Embodiment 8: on the basis of embodiment 7, according to the method described in embodiment 7, prepare the polyester polyurethane microcellular elastomer that adds low-cost polycarbonate polyol, this microcellular elastomer can be used for sole material and is especially suitable for Yulian shoes, casual shoes soles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com