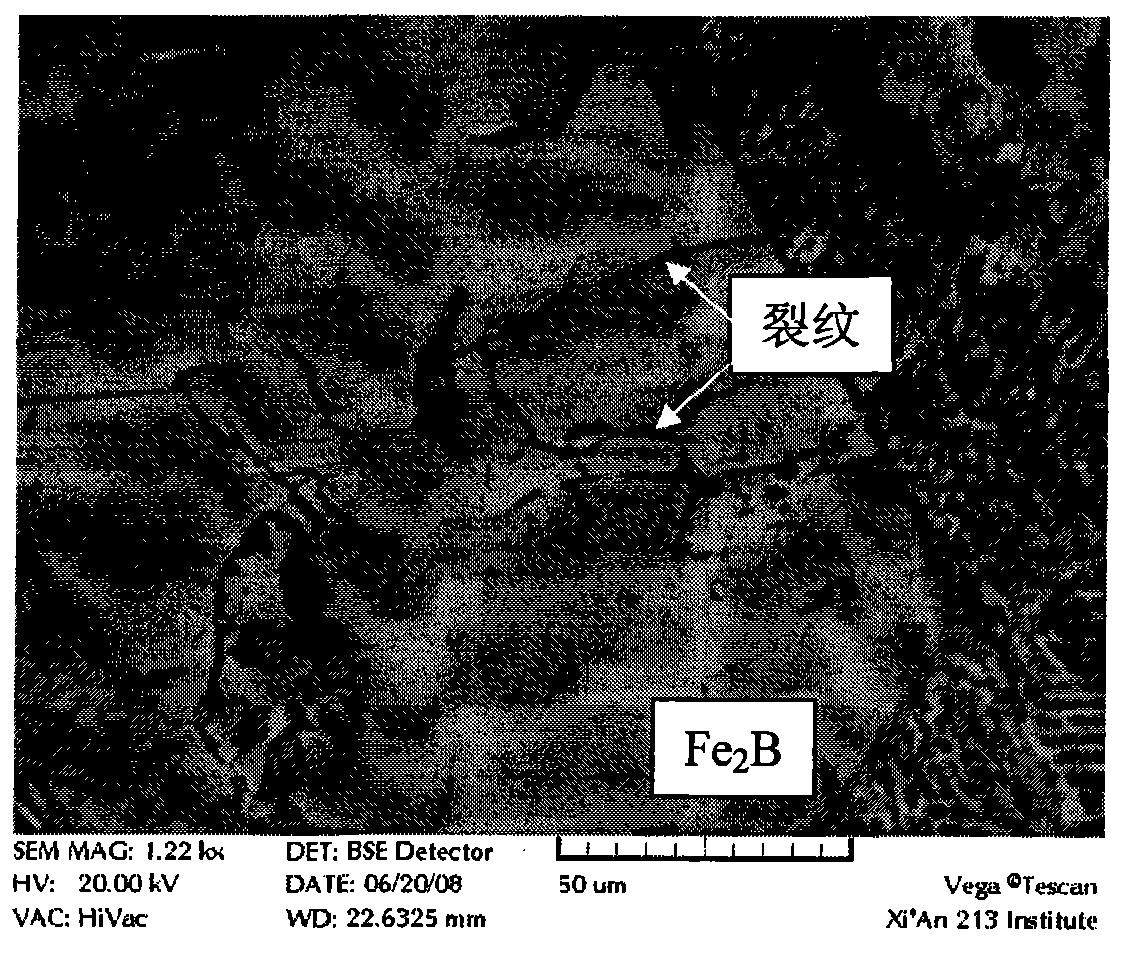

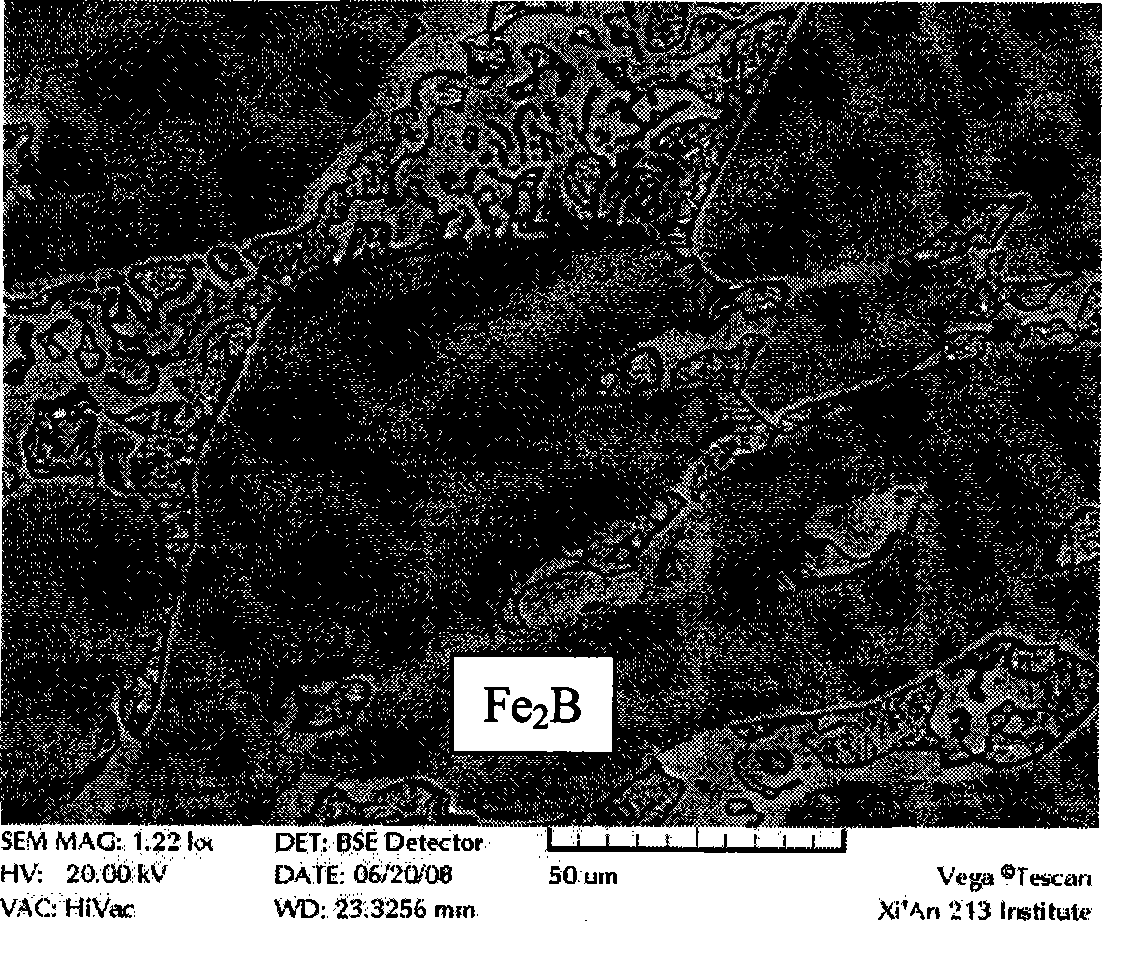

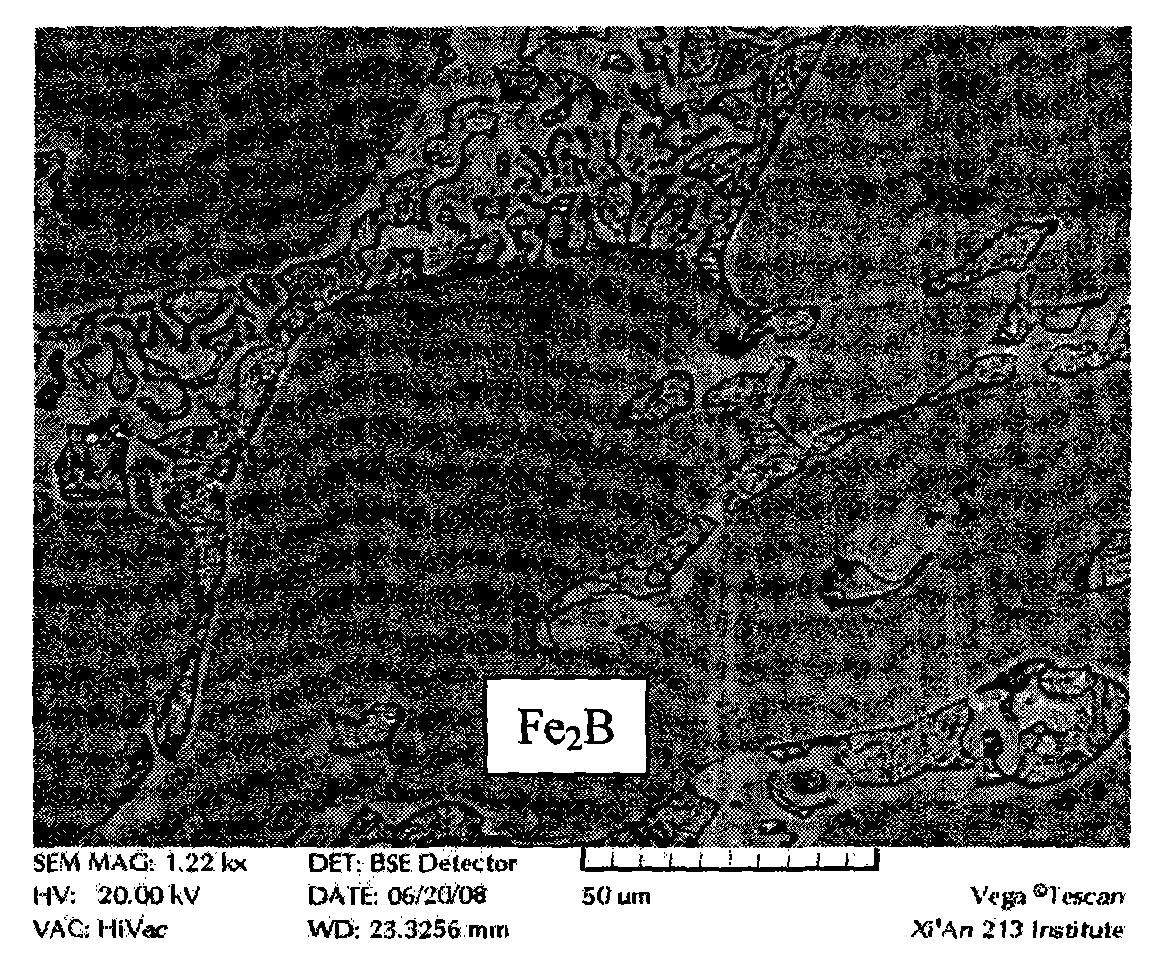

Toughening processing method of hard phase Fe2B in iron boron wear-resistant alloy

A wear-resistant alloy and toughening treatment technology, which is applied in the field of iron-boron wear-resistant casting alloys, can solve the problems of inability to play an anti-wear effect, decrease in wear performance, and peeling off, so as to improve effective anti-wear effects, improve toughness, and improve The effect of fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

[0021] (1) According to the technical solution of the present invention, the chemical composition (wt.%) of the iron-boron cast wear-resistant alloy is determined to be: C: 0.1%, B: 0.01%, Mn: 0.6%, Si<1.1%, P, S <0.04%, the rest is Fe element. On the basis of the above-mentioned chemical composition being the same, without adding Mo element, based on the total weight of grinding alloy ingredients during iron-boron casting, different weight percentages of Cr element are added, and they are respectively 0.5%, 1.0%, 3.0%, 5.0%, 7.0%, 9.0%, and 9.5%, eight groups of samples can be obtained, among which 0# sample is the sample without adding Cr element, and the others are the samples after adding Cr element, which are defined as 1#, 2 #, 3#...7# samples.

[0022] (2) According to the chemical composition determined in the step (1), and the composition of steel scrap, ferrochrome, ferromanganese and ferroboron, determine their proportioning relationship, and provide a batching wit...

Embodiment ( 2

[0028] (1) According to the technical scheme of the present invention, the chemical composition (wt.%) of determining the iron-boron casting wear-resistant alloy iron is: C:: 0.3%, B: 1.0%, Mn: 1.6%, Si<0.7%, P , S<0.04%, and the rest is Fe element. On the basis of the above chemical composition being the same, different weight percentages of Cr and Mo elements are added, based on the total weight of iron-boron cast wear-resistant alloy ingredients, the weight percentages of Cr and Mo (a total of eight percentage combinations) are shown in Table 2 As shown in , eight sets of samples can be obtained.

[0029] (2) According to the chemical composition determined in the step (1), and the composition of steel scrap, ferrochrome, ferromolybdenum, ferromanganese, and ferroboron, determine their proportioning relationship, and provide a batching with a total weight of 100 kg.

[0030] (3) Heat the scrap steel in an induction furnace to 1650°C and melt it. After the molten steel is m...

Embodiment ( 3

[0035] (1) According to the technical scheme of the present invention, determine the chemical composition (wt.%) of iron-boron casting wear-resistant alloy iron as: C: 0.4%, B: 3.5%, Mn:: 0.7%, Ca: 0.1%, Si <0.5%, P, S<0.04%, the rest is Fe element. On the basis of the above chemical composition being the same, different weight percentages of Cr and Mo elements are added, based on the total weight of iron-boron cast wear-resistant alloy ingredients, the weight percentages of Cr and Mo (a total of six percentage combinations) are shown in the table. As shown in 3, six sets of specimens can be obtained.

[0036](2) According to the chemical composition determined in the step (1), and the composition of steel scrap, ferrochromium, ferromolybdenum, ferromanganese, silicon-calcium alloy, and ferroboron, determine their proportioning relationship, and provide a total weight of 100 kilograms ingredients.

[0037] (3) Heat scrap steel in an induction furnace to 1650°C and melt it. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com