Side direction multilevel open type igniting center powder feeding vortex combustor of small oil mass gasification combustion

A swirling burner, open technology, applied in the direction of burner, burner, combustion method, etc. for burning powder fuel, can solve the problem of large amount of coal powder ignited, achieve the reduction of smoke resistance and reduce ignition energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

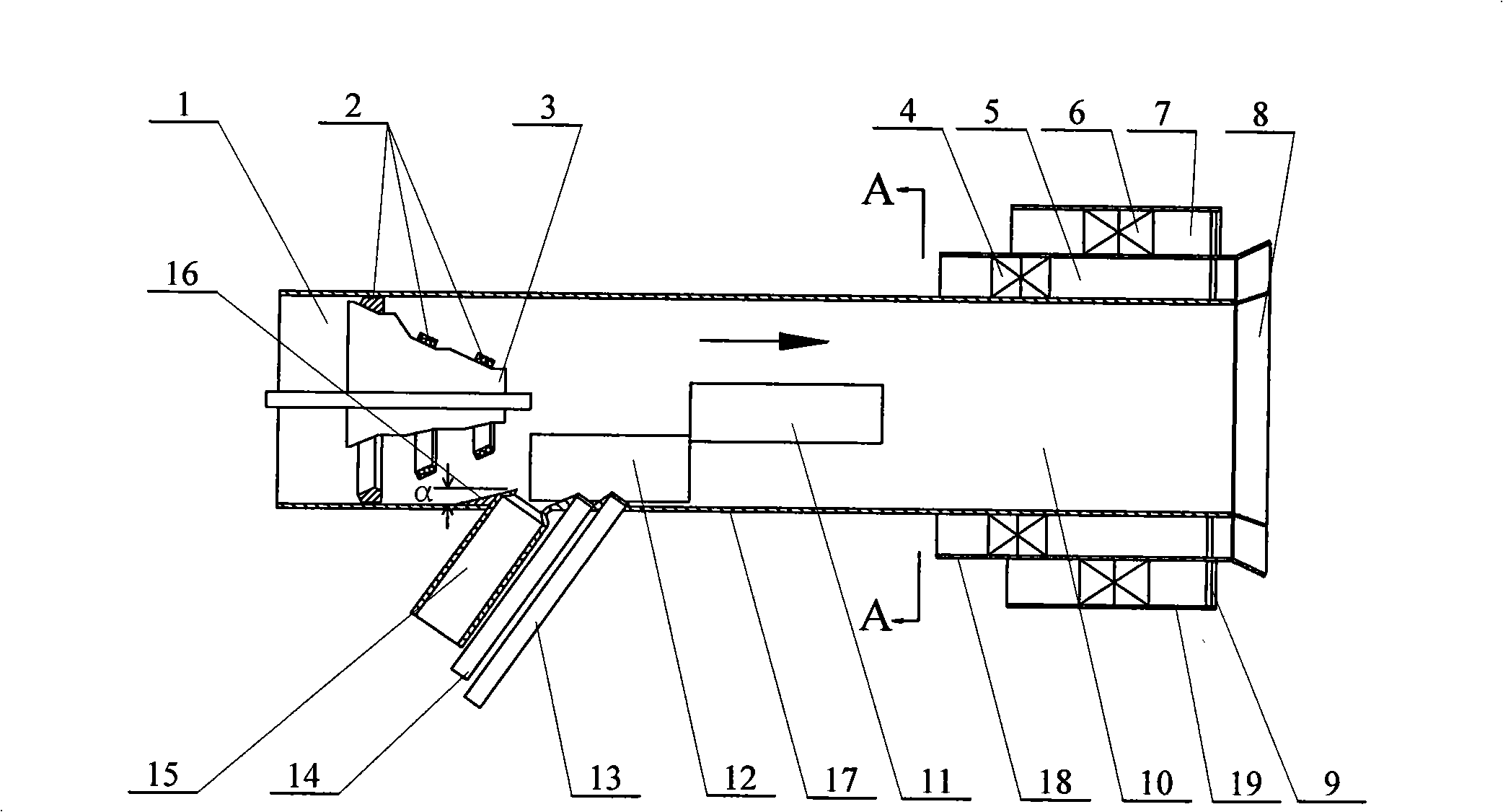

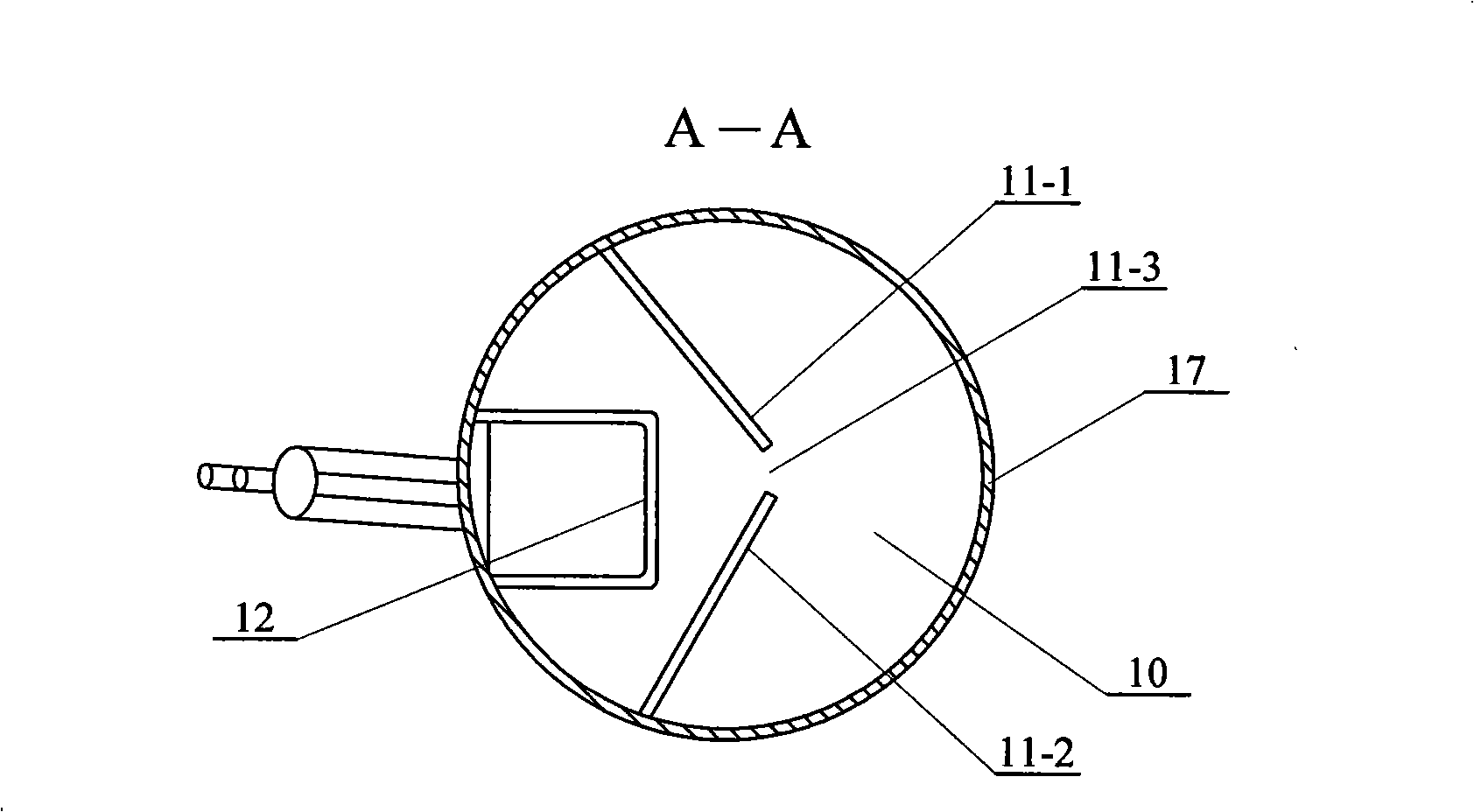

[0006] Specific implementation mode one: (see Figure 1 ~ Figure 2 ) This embodiment includes burner primary air duct 1, concentration ring 2, support plate 3, inner swirler 4, inner secondary air duct 5, outer swirler 6, outer secondary air duct 7, burner 8. Support rod 9, third-stage combustion chamber 10, second-stage combustion chamber 11, first-stage combustion chamber 12, main oil gun 15, block 16, first air duct pipe 17, second air duct pipe 18 and The third air duct pipe 19, the primary air duct 1 of the burner is inside the first air duct pipe 17, the outlet end of the first air duct pipe 17 is the burner 8, and the support plate 3 is fixed at the entrance of the first air duct pipe 17 end, the concentration ring 2 is fixed on the support plate 3, the first-stage combustion chamber 12 is fixed in the first air duct pipe 17 at the front end of the support plate 3, and the second-stage combustion chamber 11 is fixed on the first-stage combustion chamber 12 at the front ...

specific Embodiment approach 2

[0007] Specific implementation mode two:. (see Figure 1 ~ Figure 2 ) The difference between this embodiment and the specific embodiment one is that it increases the auxiliary oil gun 13, the auxiliary oil gun 13 is arranged in parallel with the main oil gun 15, the auxiliary oil gun 13 communicates with the first-stage combustion chamber 12, and the auxiliary oil gun 13 is connected with the first-stage combustion chamber 12. The outlet end of the gun 13 is arranged in the middle of the combustion chamber 12 of the first stage. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0008] Specific implementation mode three: (see Figure 1 ~ Figure 2 ) The difference between this embodiment and the specific embodiment two is that it has increased the flame detection device 14, and the flame detection device 14 is arranged between the auxiliary oil gun 13 and the main oil gun 15, and the flame detection device 14 and the first-stage combustion chamber 12 connected. Others are the same as in the second embodiment.

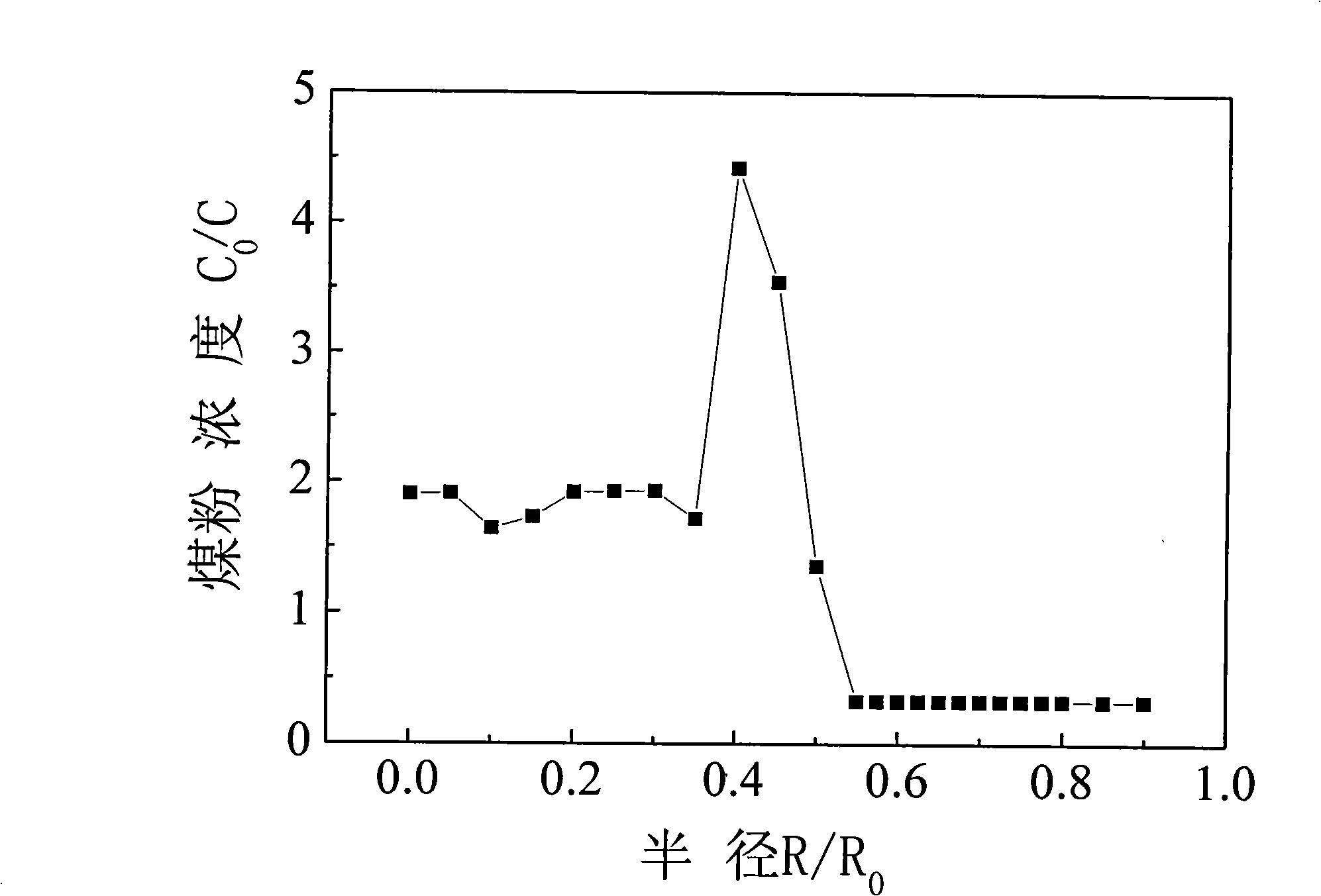

[0009] The pulverized coal is sent into the primary air duct 1 of the burner, and the pulverized coal is concentrated through the pulverized coal concentrator 2, and a high concentration of pulverized coal is formed in the central area of the primary air duct 1 of the burner. The 600MW subcritical boiler is calculated by fluent software Concentration distribution results such as ( image 3 As shown), the high concentration area of pulverized coal is in the center of the primary air duct 1 as the center of the 0.6R 0 Within, the rest is li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com