Prefabricated light thin type low temperature hot water floor radiation heating system

A low-temperature hot water and radiant heating technology, which is applied in hot water central heating systems, heating systems, heating methods, etc., can solve the problems that cannot be simply applied to the renovation of old buildings, cannot meet the heating requirements, and the thickness of the product affects the height of the floor. , to achieve the effect of clear responsibility determination, wide selection of heat sources, and reduction of load-bearing design standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

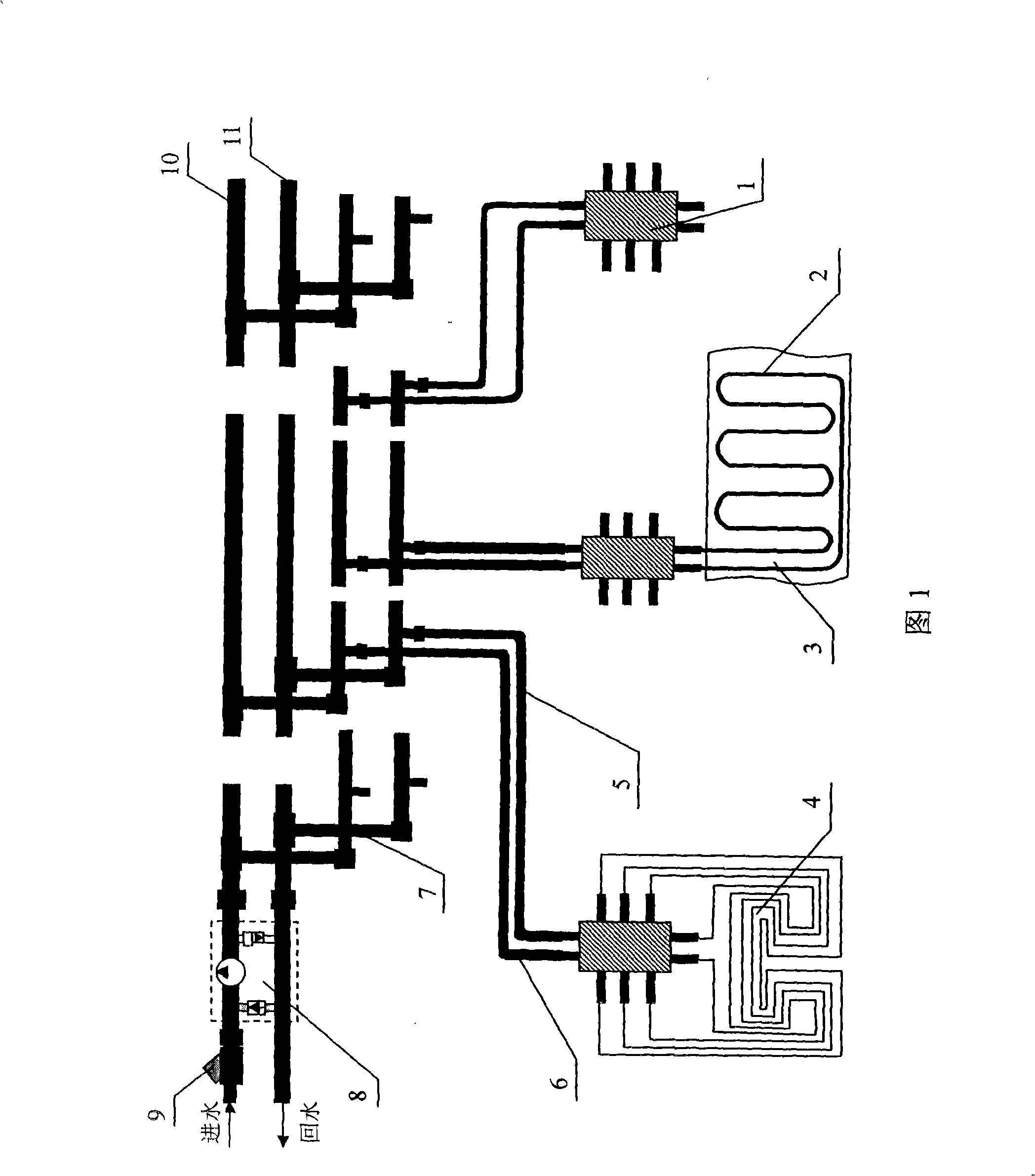

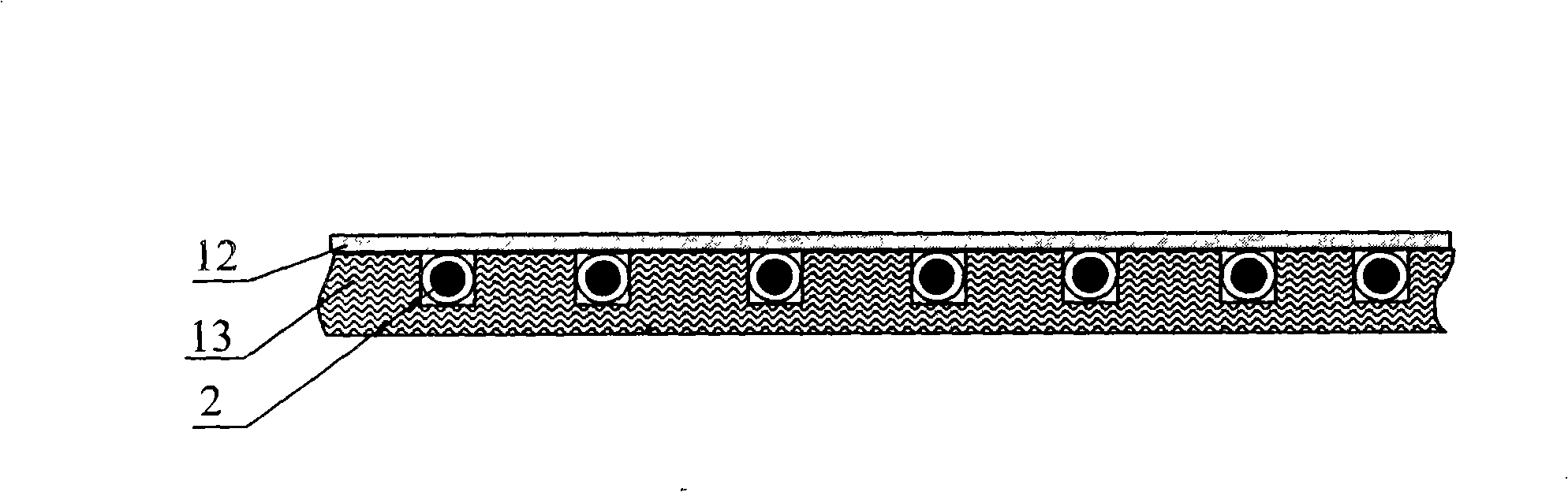

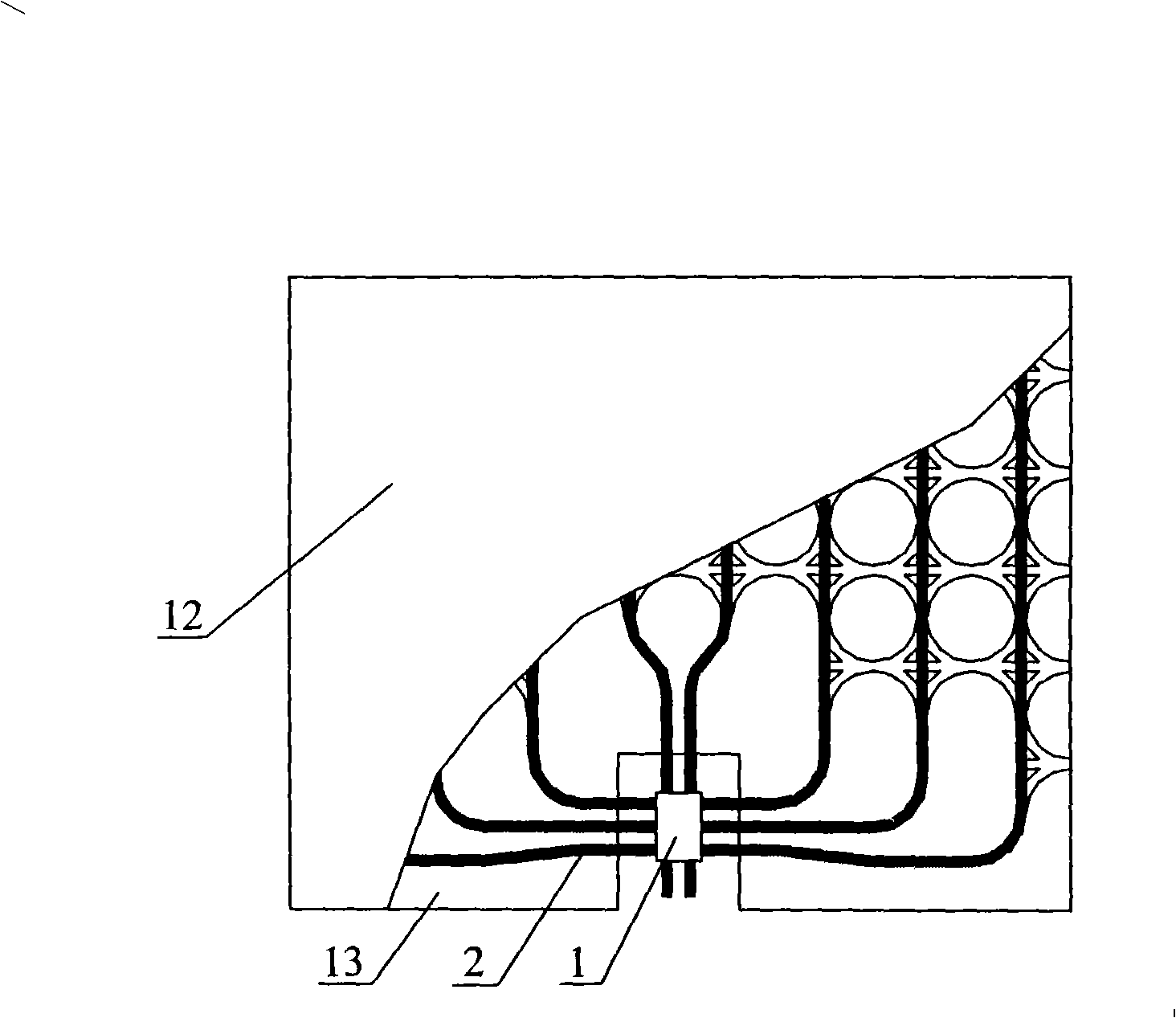

[0044] Please refer to Fig. 1, a prefabricated light and thin low-temperature hot water floor radiant heating system of the present invention is a mountain filter device 9, a water mixing device 8, a primary water collector system 7, and a secondary water collector system 1 , total water supply pipe 10, total return water pipe 11, contact water supply pipe 6, contact return water pipe 5, heating loops 3, 4, heating pipe 2 and insulation board 13; among them, the primary water collector system 7 and the secondary The water collecting and distributing system 1 is composed of 1 to N primary water collecting and distributing devices 7 and 1 to N secondary water collecting and distributing devices 1 according to the size of the heating area; According to the specific housing conditions, 1 to N secondary water collectors are selected, and each secondary water collector 1 adopts 1 to N heating circuits 3 according to the design requirements. The hot water reaches the water mixing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com