Die enterprise informatization management system

An enterprise informatization and management system technology, applied in the field of mold enterprise management subsystem, can solve the problems of backward design and management methods, restricting enterprise development, long design and manufacturing cycle, etc., achieve paperless and unified management, improve information The speed of delivery and the effect of saving office costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

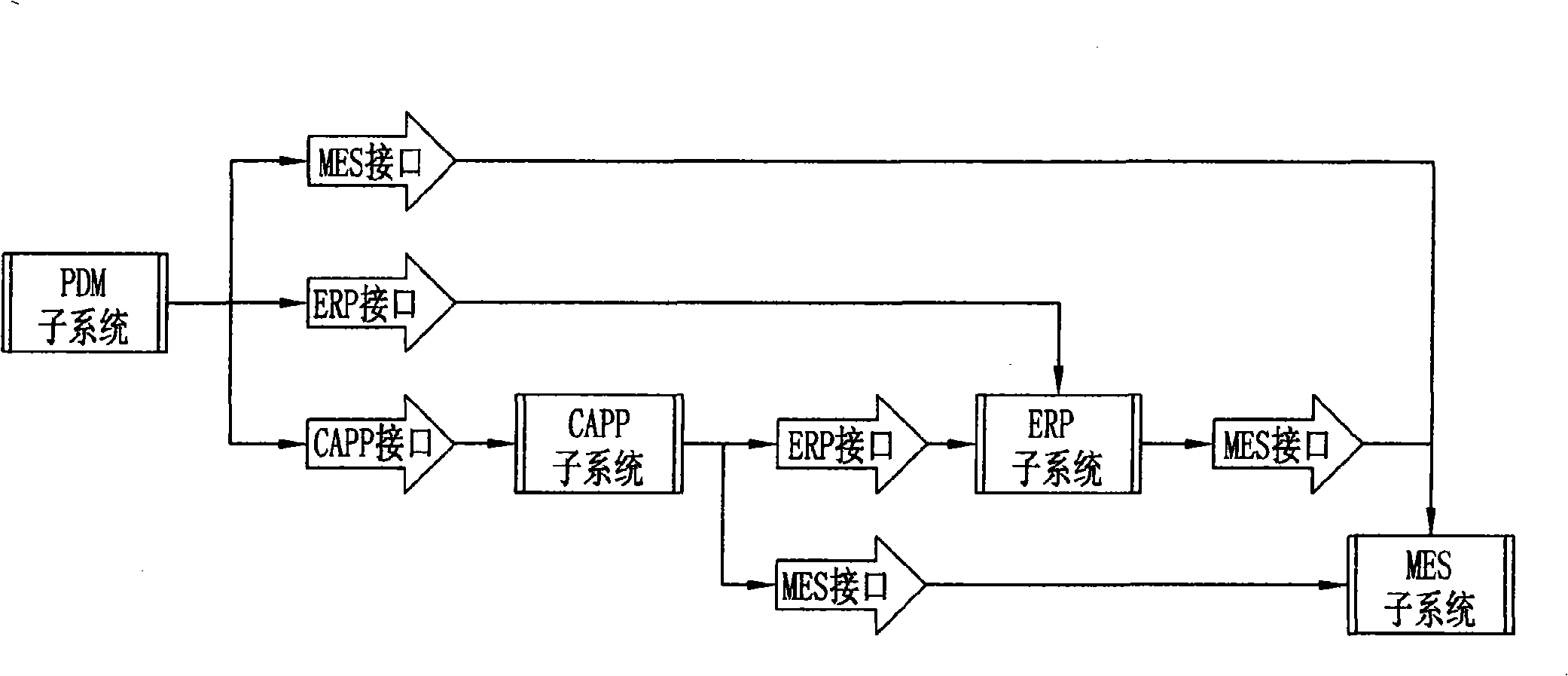

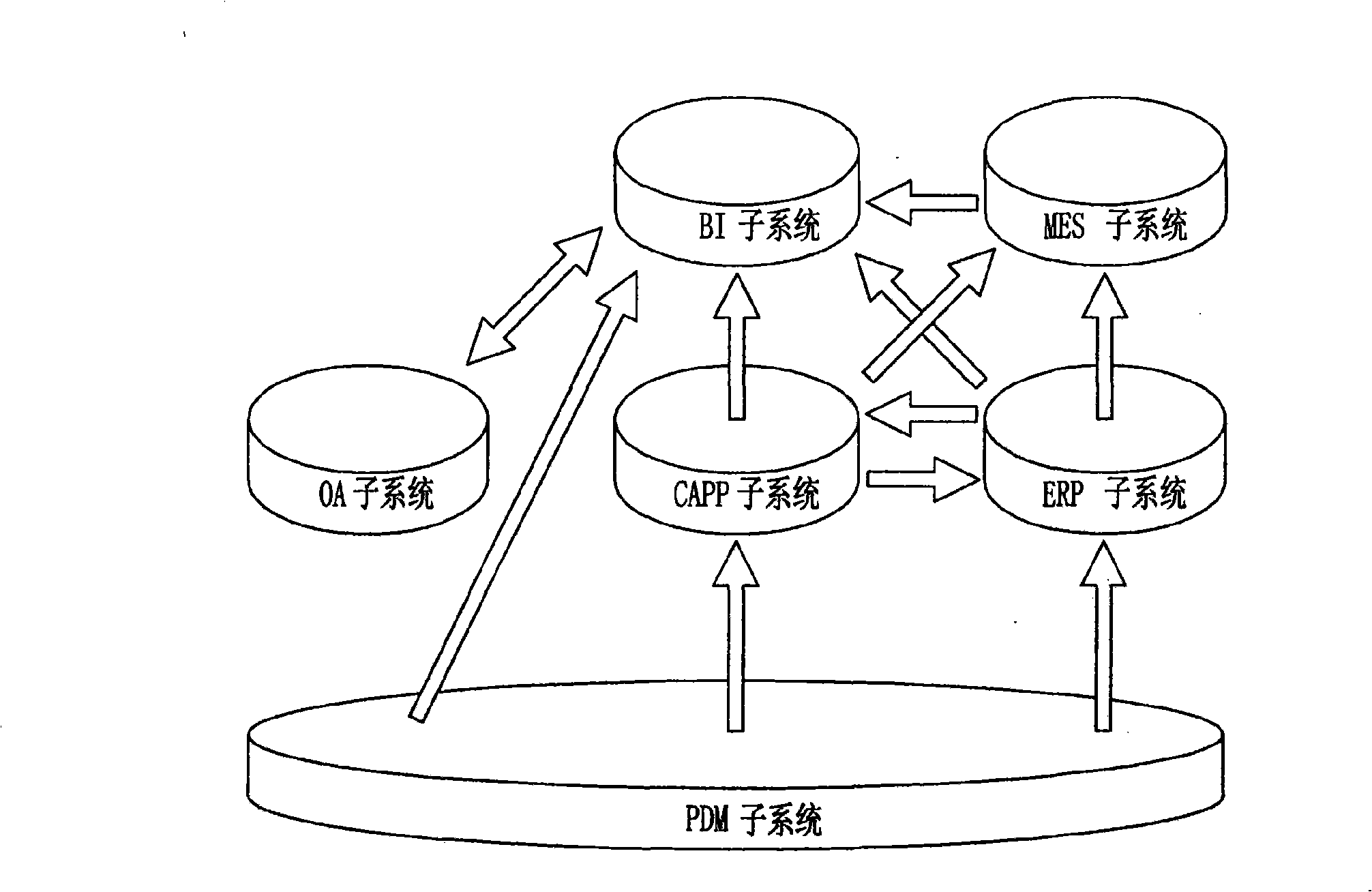

[0023] Such as figure 1 , figure 2 As shown, the mold enterprise information management system includes several subsystems connected through the network, and the subsystems include:

[0024] Product Data Management Subsystem (PDM, Product Data Management): Provides a basic management platform for the entire subsystem. It provides a guarantee for the interoperability of other different application subsystems and tools with a unified data format and user interface;

[0025] Computer Aided Process Planning Subsystem (CAPP, Computer Aided Process Planning): All source data comes from the PDM management platform, which is used to compile mold processing technology, count castings, forgings, standard parts and working hours information, and publish the process information to ERP Subsystem, which provides basic data for ERP subsystem to prepare production plan;

[0026] Enterprise Resource Planning Subsystem (ERP, Enterprise Resource Planning): All source data comes from the PDM m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com