Low-carbon sulfur-automatic steel with good cutability

A free-cutting steel and machinability technology, applied in the field of low-carbon sulfur free-cutting steel, can solve problems such as the deterioration of the roughness of the machined surface, and achieve the effect of good surface roughness and inhibiting the formation of pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

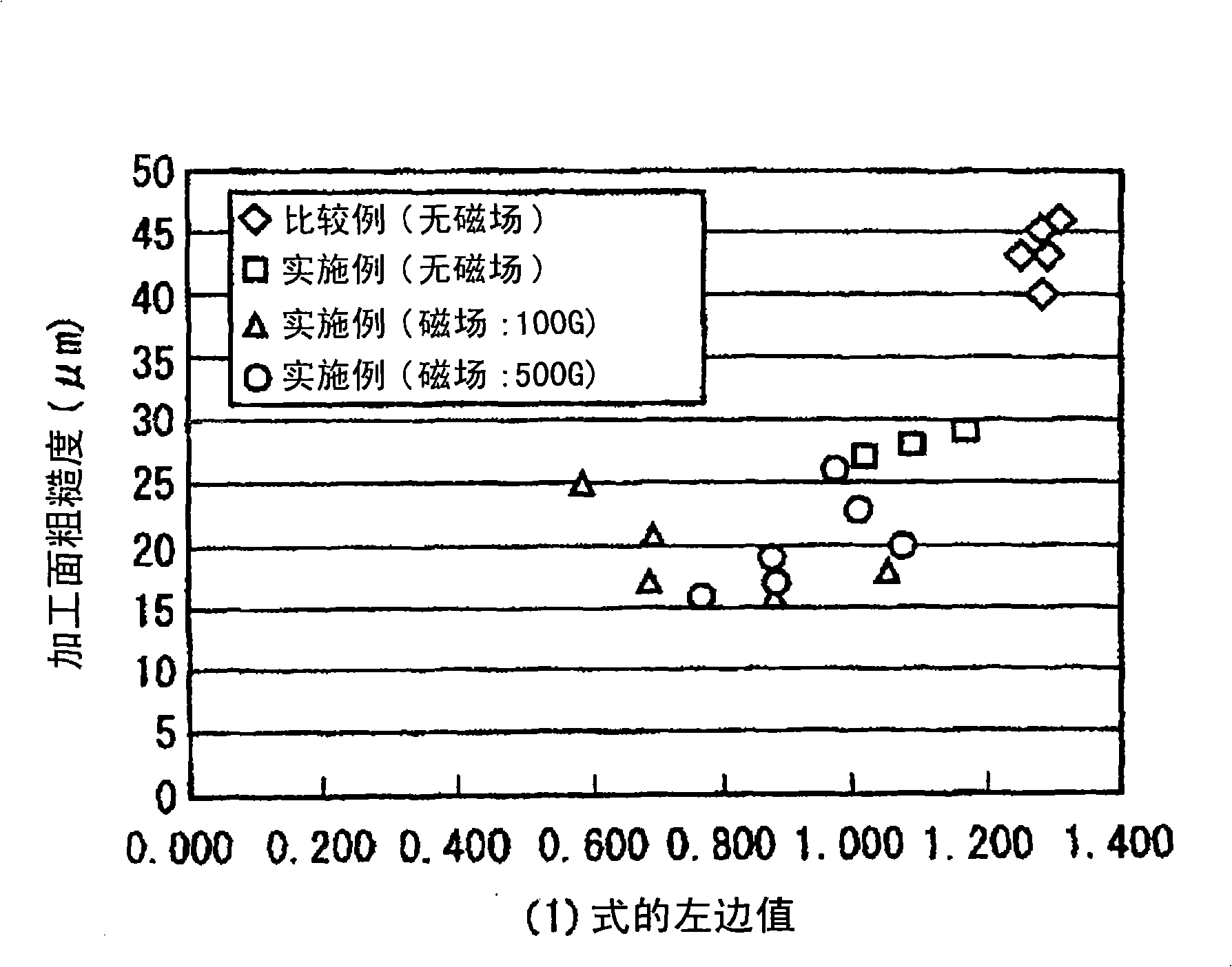

[0103] Various molten steels are smelted by changing the content of Si, Mn, S, Al, N, etc. by using a molten steel treatment facility consisting of a 3t-scale induction furnace, a 100t converter, and a ladle. At this time, Si and Al are adjusted by changing the Si concentration and Al concentration in the added Fe—Mn alloy and Fe—S alloy. Before casting the molten steel obtained in this way into a predetermined mold, it was measured using a free oxygen detector (trade name "HYOP10A-C150" manufactured by Heleus Electronite Co., Ltd.) to obtain a free oxygen concentration.

[0104] In addition, when performing continuous casting of a slab with a cross-section of 300mm×430mm or using a 3t-scale induction furnace, a cast iron mold (section size 300mm×430mm) designed for the same cooling rate as the slab is used. , Cast molten steel. At this time, if necessary, a magnetic field is applied to the mold to perform electromagnetic stirring.

[0105] The obtained slab (or ingot) was s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com