Cold-forging precise forming technique of gear sleeve

A precision forming and gear sleeve technology, which is applied in the field of gear sleeve cold forging precision forming process and the cold forging precision forming process of the gear sleeve, can solve the problems of long gear sleeve forming process, low product qualification rate, and high material consumption, etc. Achieve the effect of shortening the processing process, improving the overall quality and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

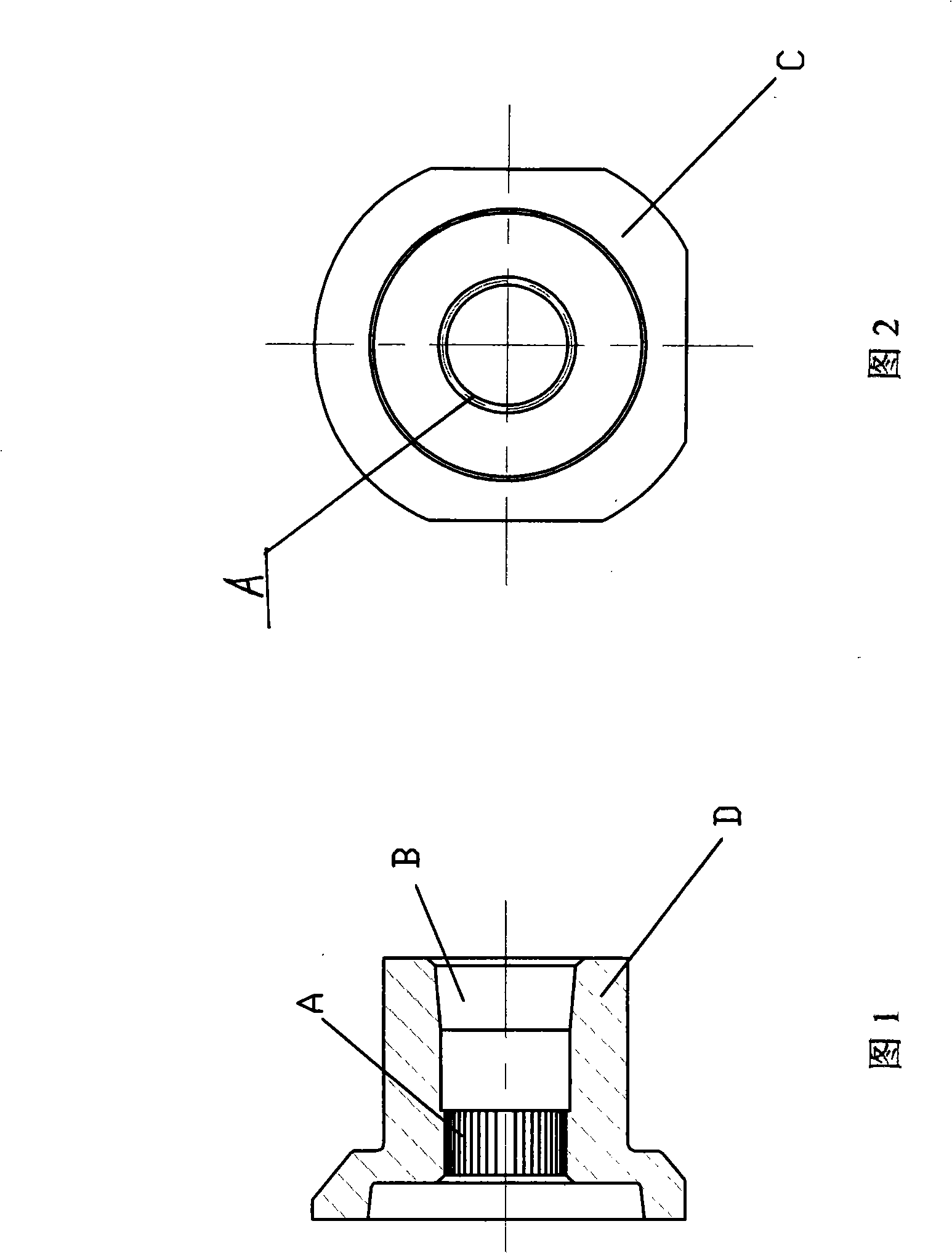

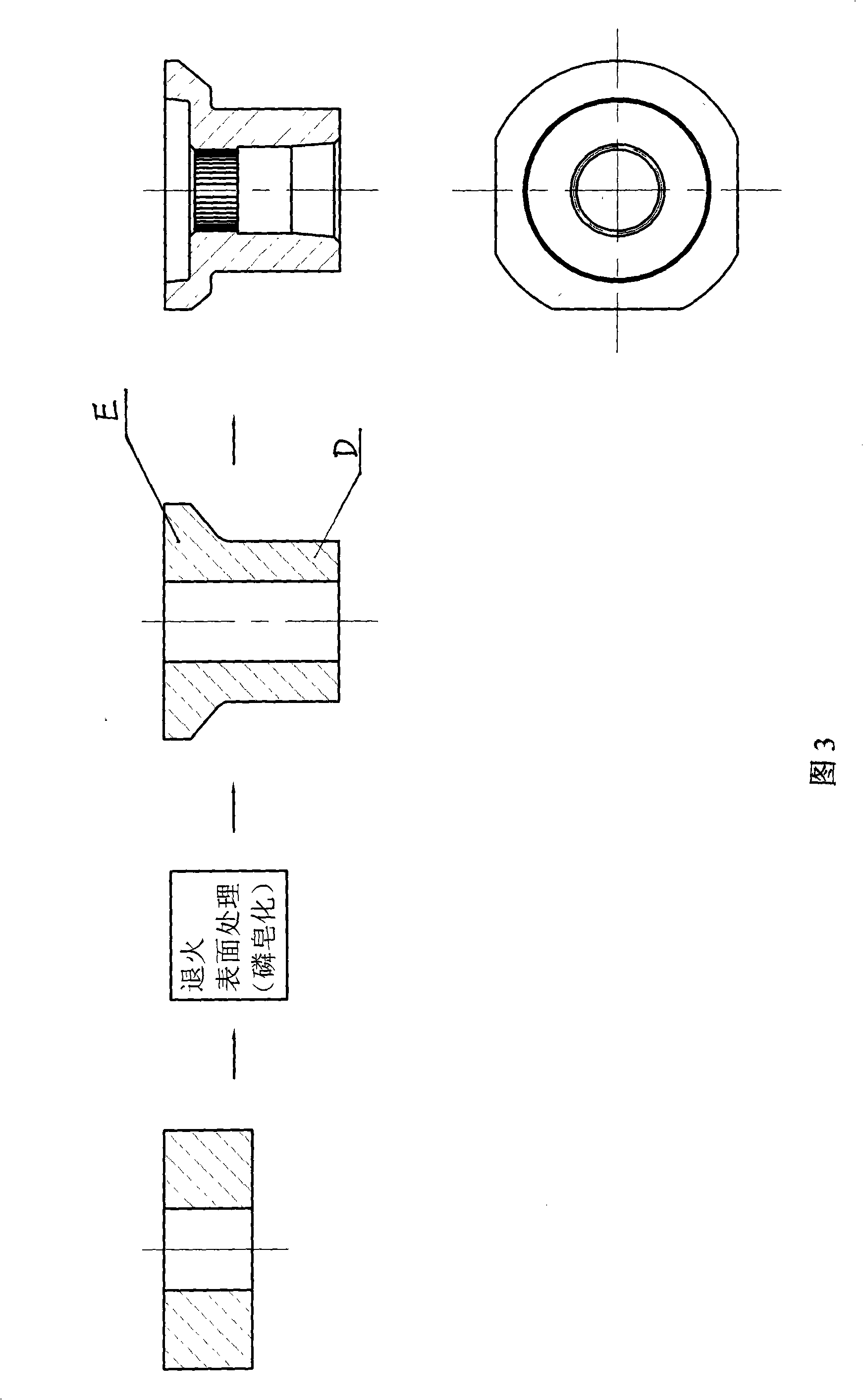

[0022] As shown in Figure 3, it is a cold forging process flow chart. A cold forging precision forming process for gear sleeves is as follows: the first step is to blank the alloy steel pipe billet with a circular saw, and the weight error between the blank blank and the gear sleeve ±0.5 grams;

[0023] In the second step, the blank steel tube is annealed in a pit furnace at 850°C for 6 hours, and then cooled to 300°C along with the furnace and released;

[0024] The third step is to phosphatize and saponify the annealed steel tube blanks according to the conventional process using a phosphorus saponification line to form a surface lubricating layer. The phosphating temperature is 80°C and the time is 20 minutes; the saponification temperature is 60°C. The time is 10 minutes;

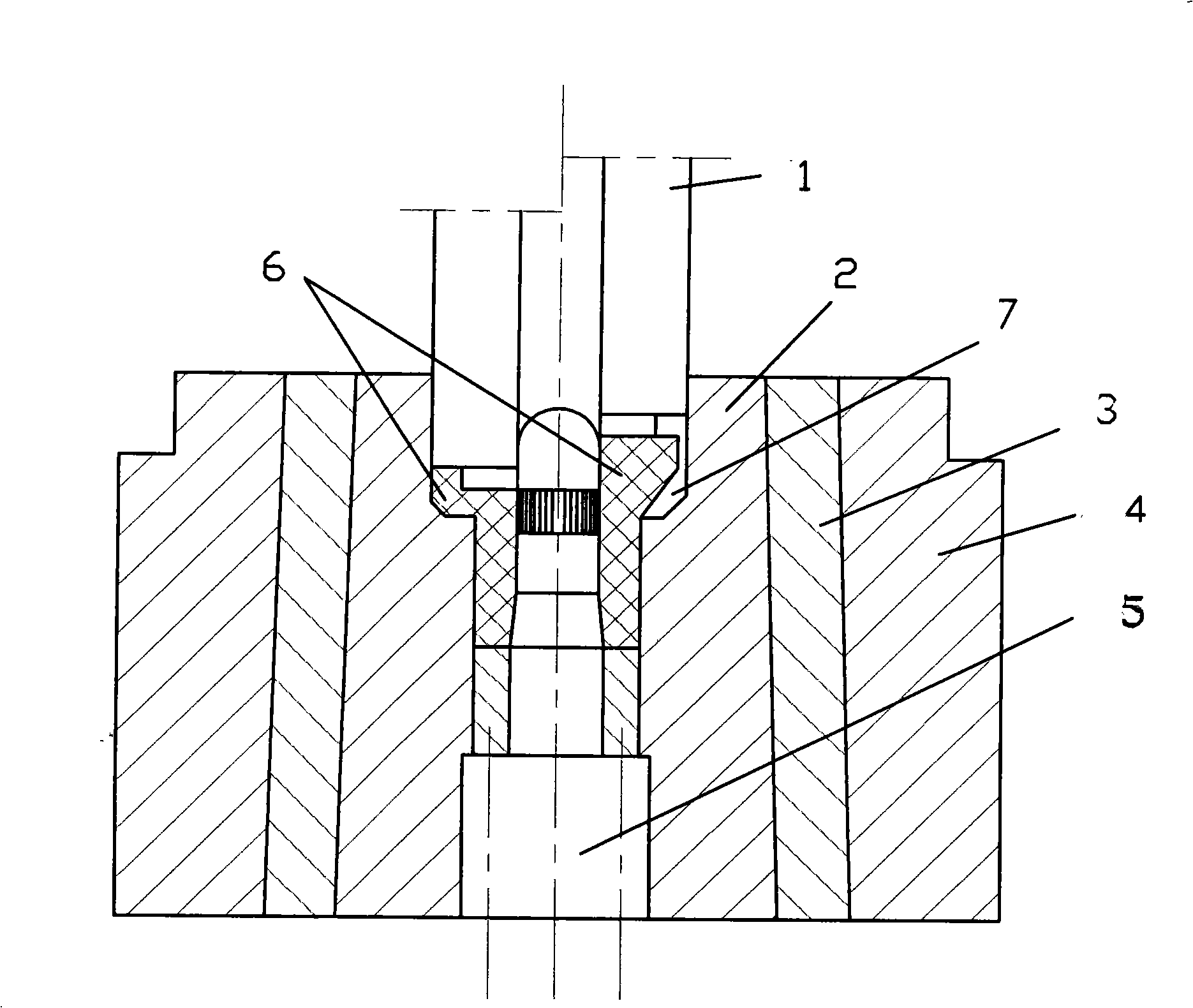

[0025] The fourth step is to use high-strength die steel to manufacture pre-formed molds and occluded forging molds;

[0026] The fifth step is to use a 400T mechanical press, a four-column universal die se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com