Low powered steel-plate cutter

A cutting machine and steel plate technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of large thermal strain, high laser light source power, and poor beam quality, and achieve high beam quality and high brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical means of the present invention will be described in detail as follows. It is believed that the purpose, characteristics and characteristics of the present invention can be obtained from this in-depth and specific understanding. However, the following examples and illustrations are only provided for reference and illustration, and are not used to explain the present invention. be restricted.

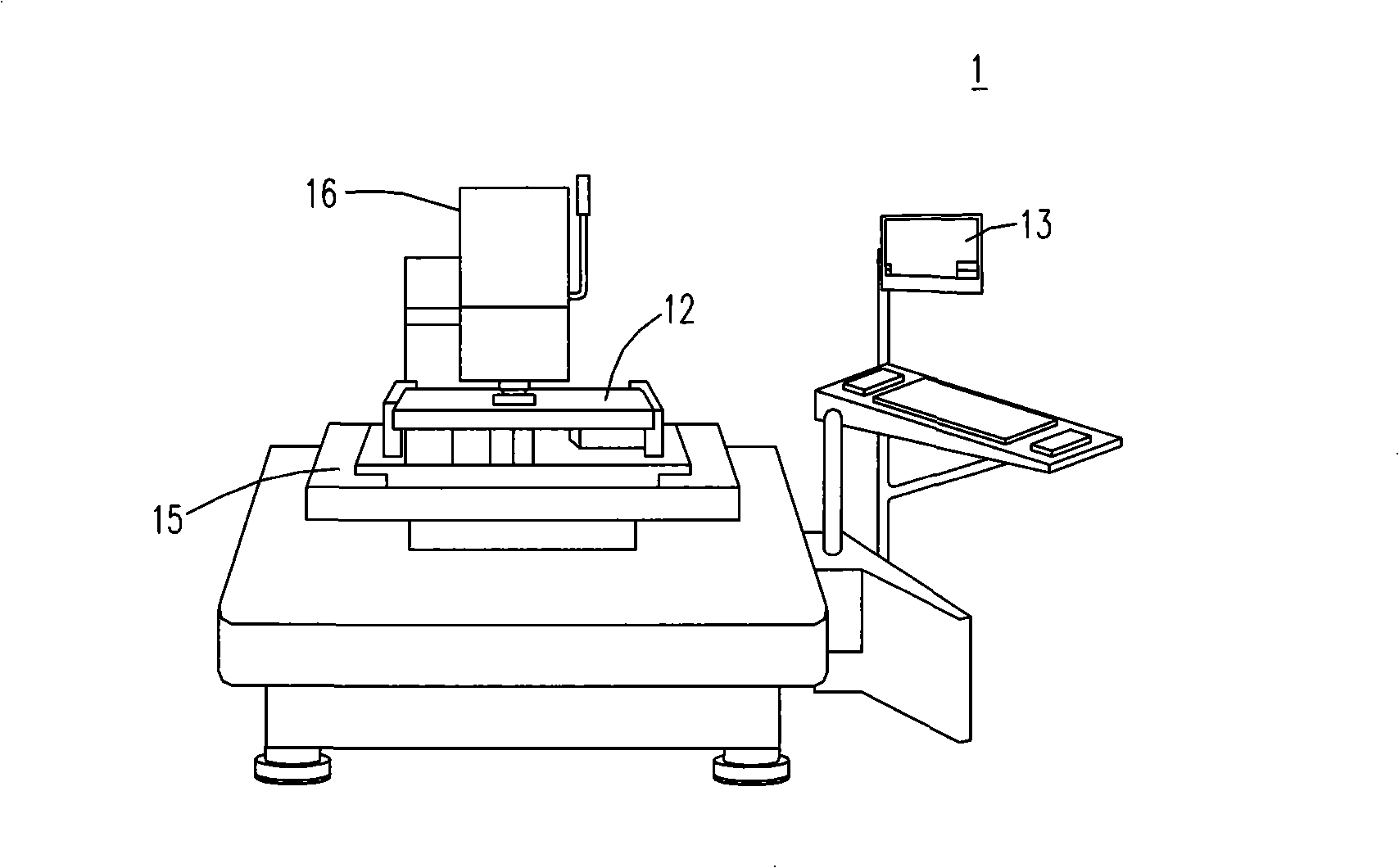

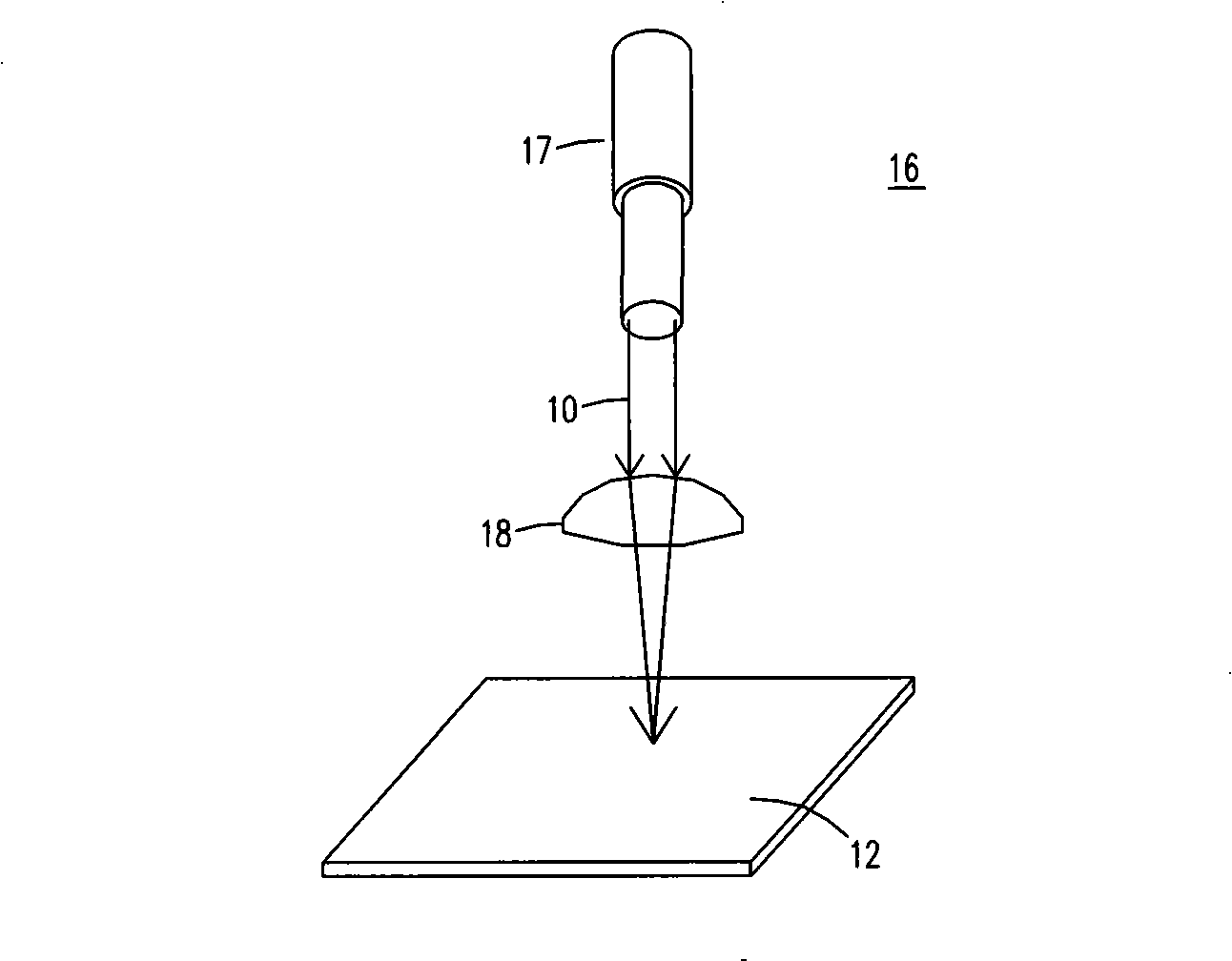

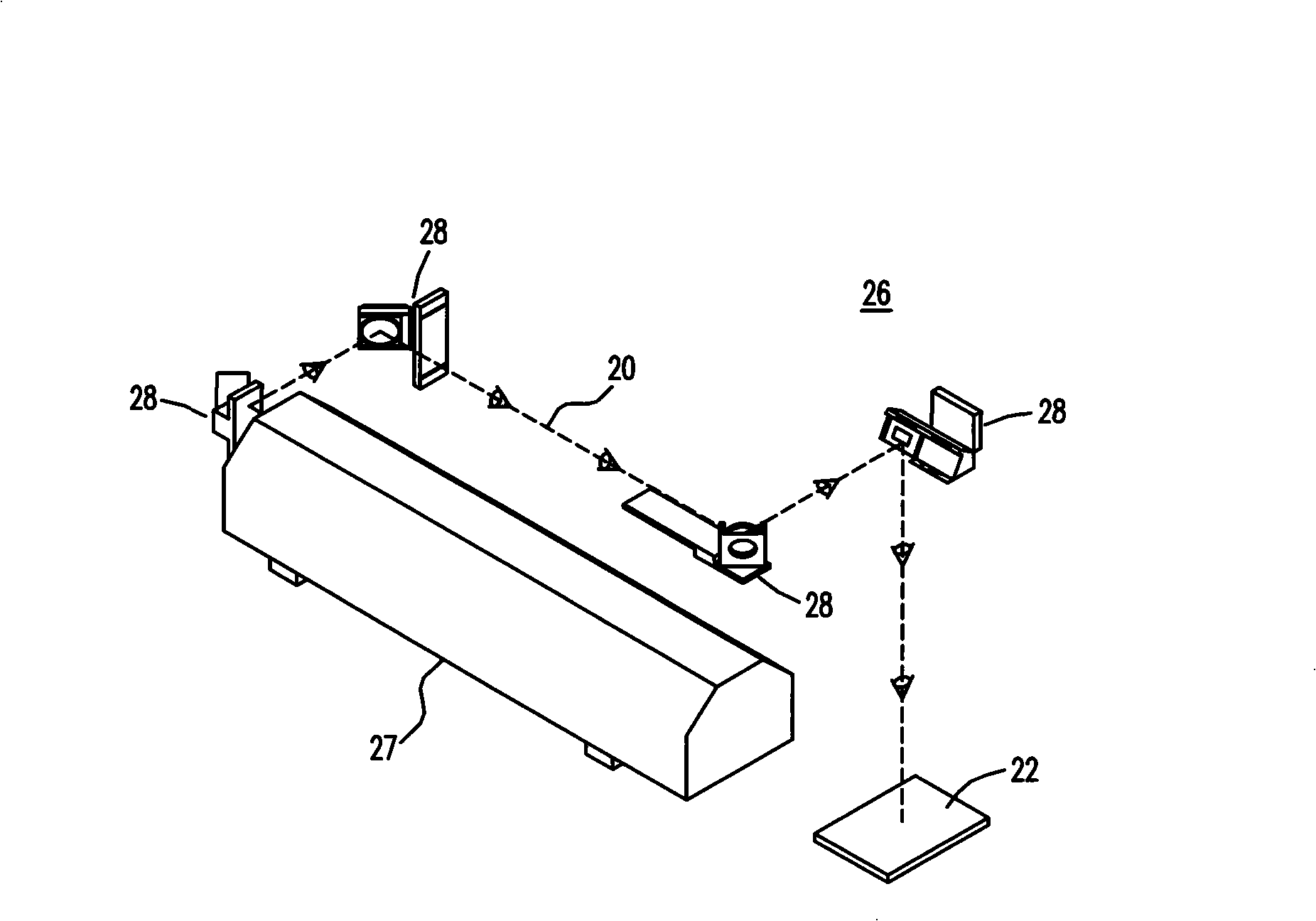

[0029] Please refer to Fig. 1 (A) at first, it is the schematic diagram of the first embodiment of steel plate cutting machine of the present invention, and this steel plate cutting machine 1 comprises a control system 13, a carrying device 15, and a light source system 16; The control system 13 is used to control the operation of the steel plate cutting machine 1, which can include various hardware equipment suitable for the steel plate cutting machine 1, and other software designed according to product requirements; the carrying device 15 is used to carry the steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com