Process for making full-degradable paper mulching film for agricultural use from agronomic crop stalks

A technology of paper mulch and wind and rain, applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of production decline, high price, and restrictions on the promotion and application of agricultural film, and achieve the effect of increased strength and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] For the purchase of crop stalks, purchase and processing points are set up in rural areas, and this work is handed over to local farmers. Processing and pre-treatment are handled by the processing point. The enterprise and the processing point sign a contract on how much processed raw material is needed each year. The factory only stores processed raw material for 15 days at most.

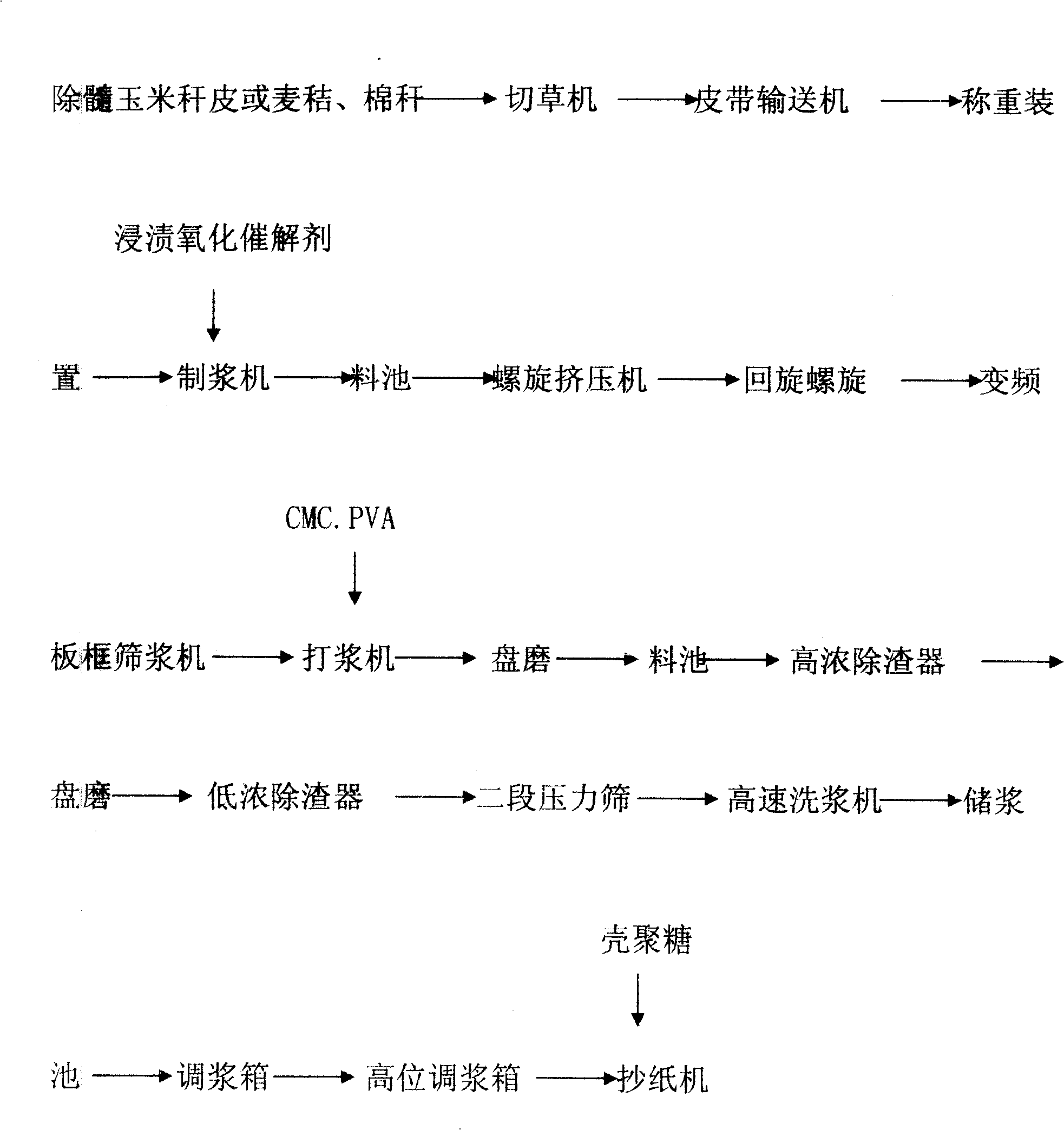

[0017] When the raw materials arrive at the factory, they are directly fed into the pulp and paper production line. The process flow is shown in the attached drawing, which is the process flow chart of the paper mulching film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com