Shallow groove isolation construction and forming method thereof

A technology of isolation structures and shallow trenches, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as short circuits between word lines, reduce internal stress of the substrate, and achieve the effect of providing stress relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

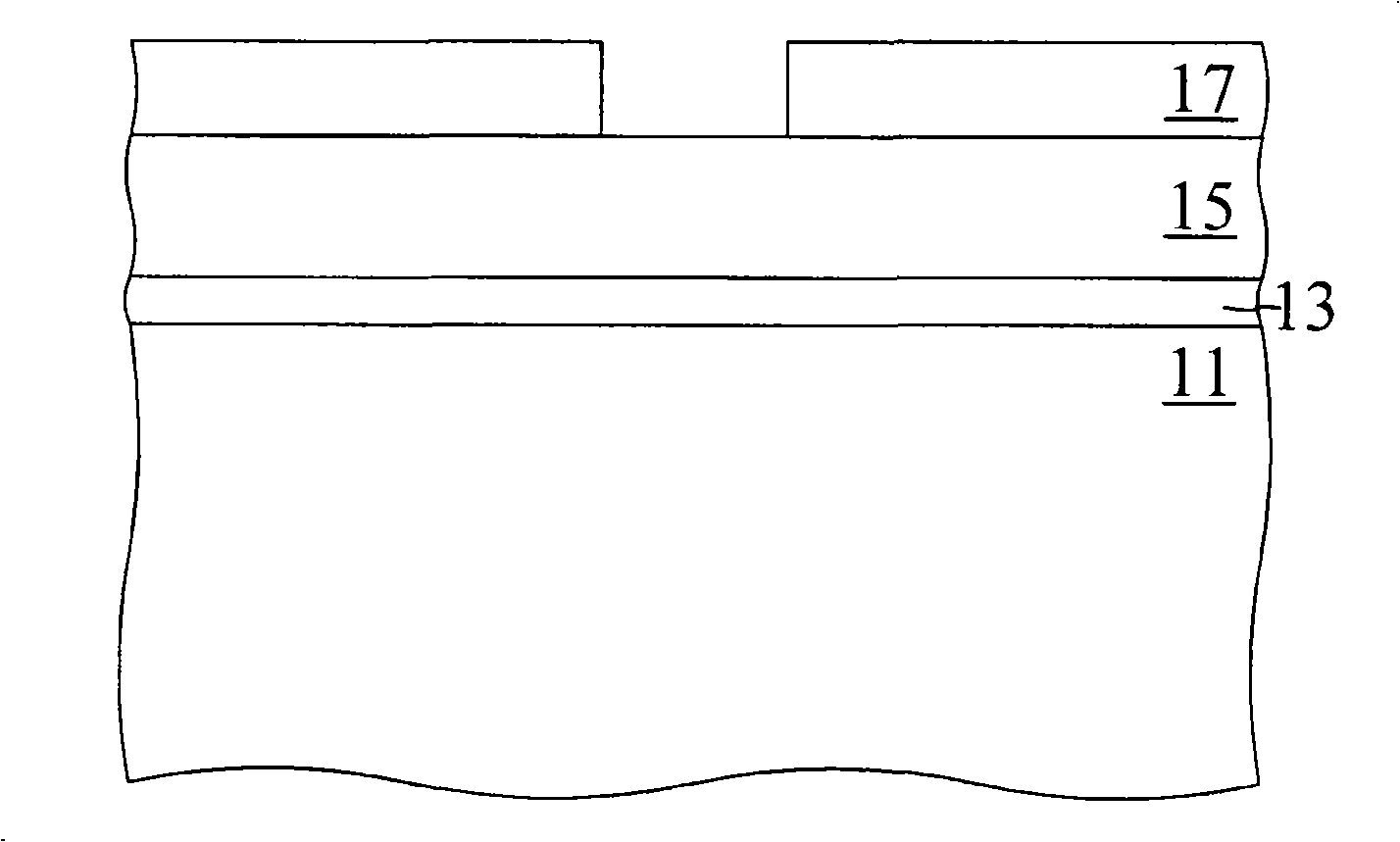

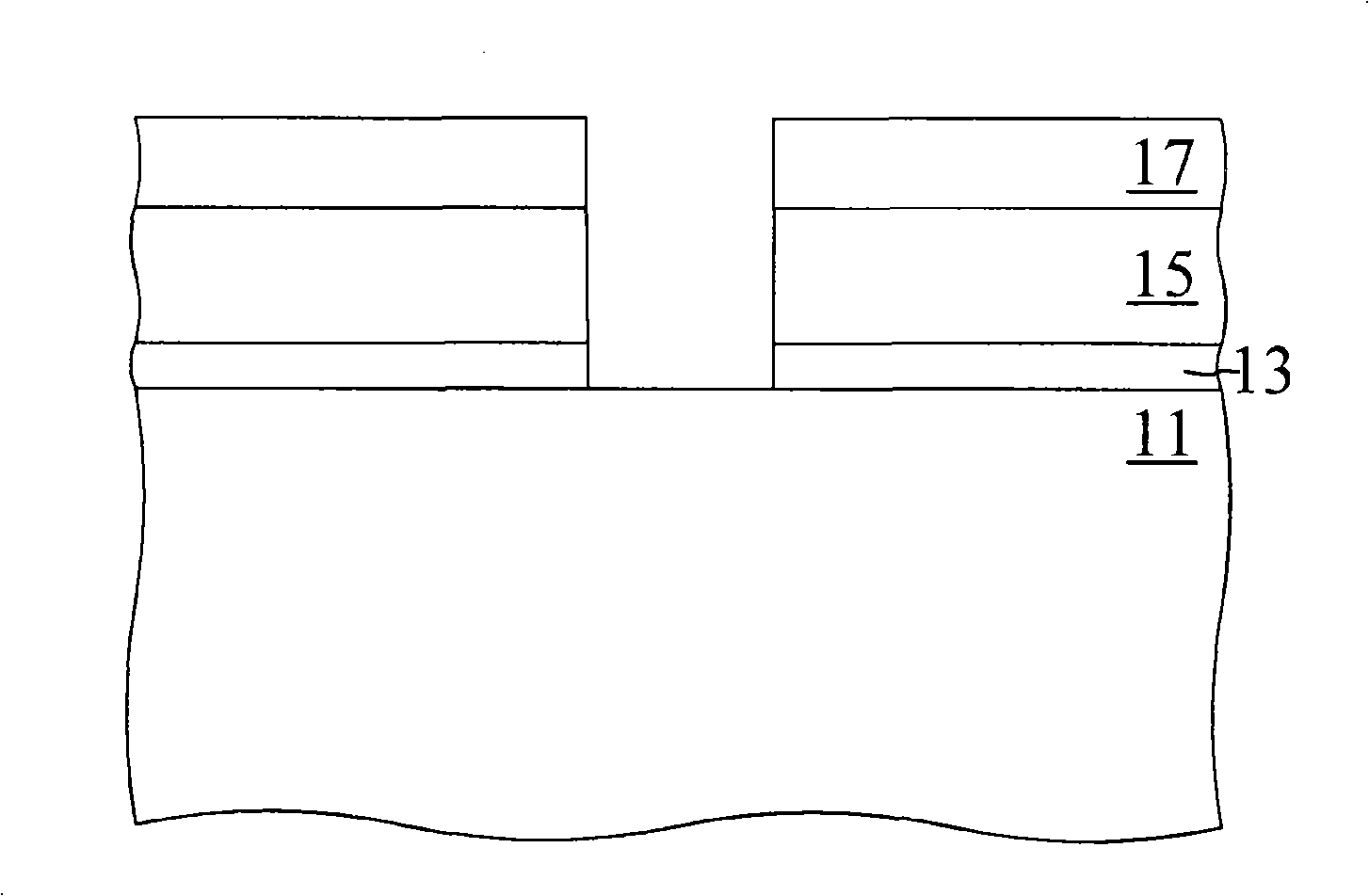

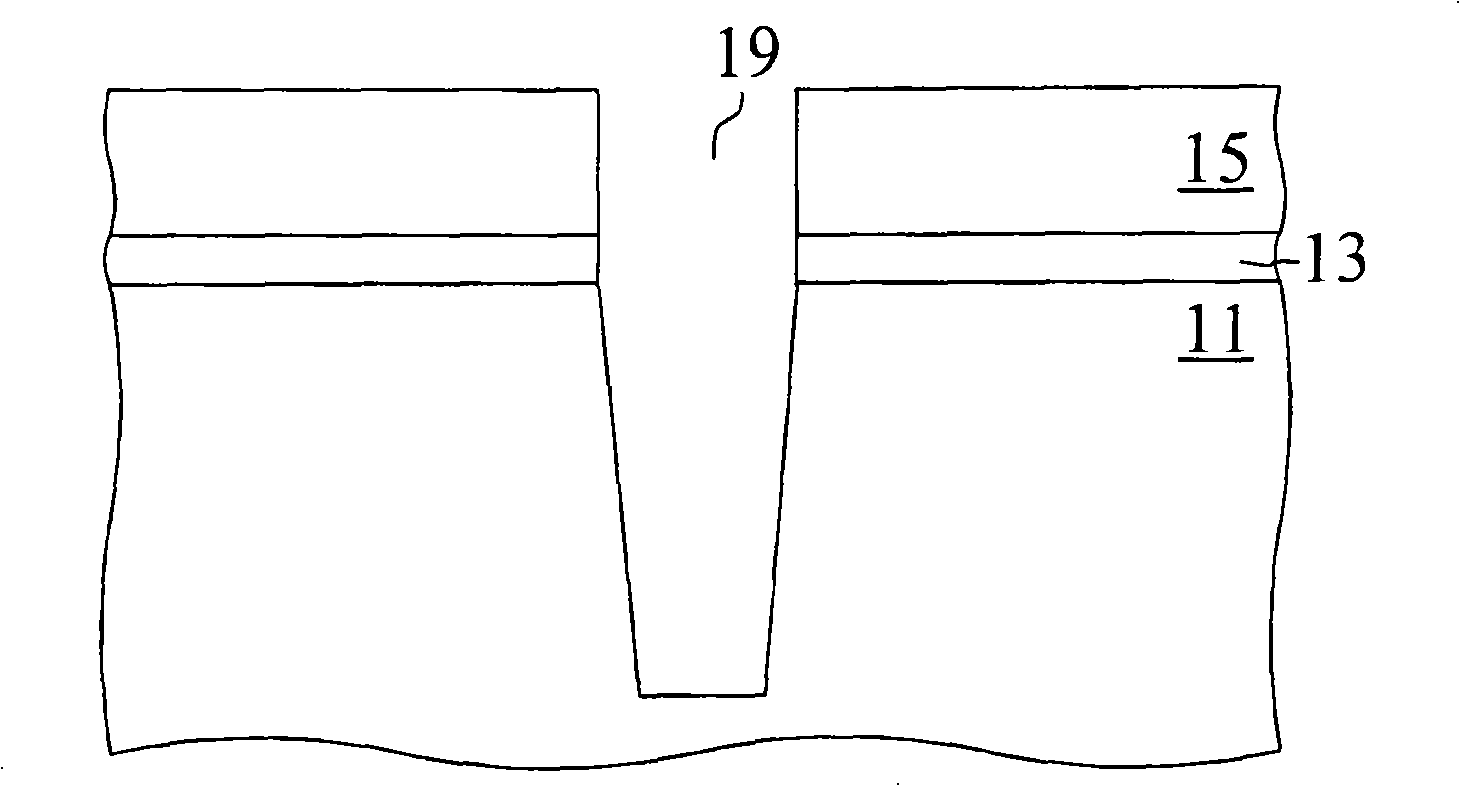

[0023] Firstly, a trench substantially having a wide top and a narrow bottom is formed in the substrate by conventional techniques. In detail, refer to Figure 2A , sequentially forming a pad oxide layer 203 and a pad nitride layer 205 on a substrate 201 to obtain a substrate 207 having the substrate 201 , the pad oxide layer 203 and the pad nitride layer 205 . Wherein, the method of forming the pad oxide layer 203 may be, for example (but not limited to): performing a thermal oxidation process on the substrate 201 at an appropriate temperature in an oxygen-containing environment free of moisture; in addition, the pad nitride layer 205 can be provided by, for example, but not limited to, a low pressure chemical vapor deposition process. The total thickness of the pad oxide layer 203 and the pad nitride layer 205 is generally 80 to 200 nanometers (nm), preferably 90 to 120 nanometers (nm), such as about 100 nanometers (nm).

[0024] Afterwards, a patterned photoresist layer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com