Laser for laser cutting machine

A laser cutting machine and laser technology, applied in the field of lasers, can solve the problems of low output power, shallow cutting depth, slow cutting speed, etc., and achieve the effect of large output power, deep cutting depth and fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

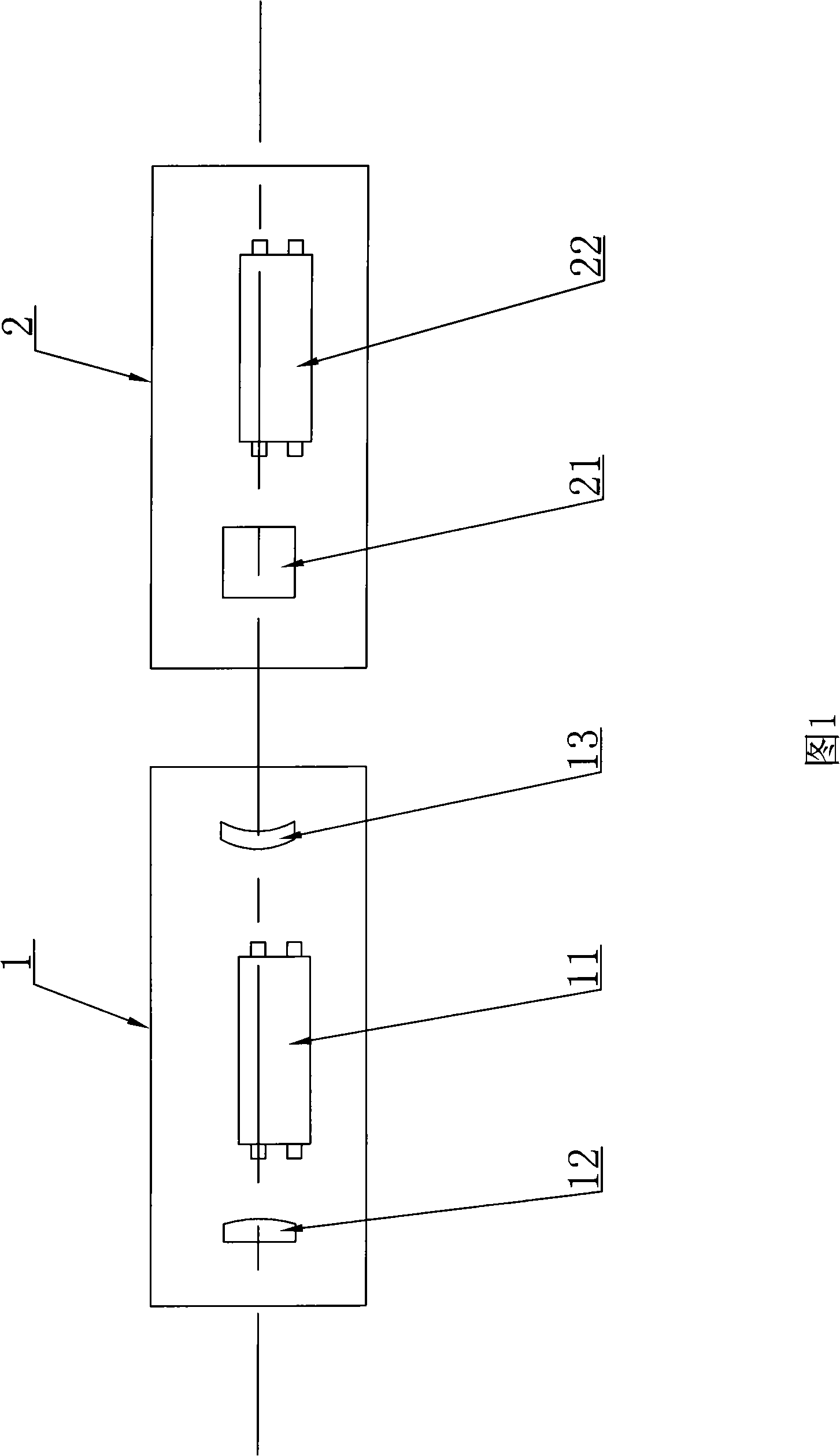

[0010] As shown in Figure 1, a kind of laser device that is used on the laser cutting machine comprises: Oscillation stage 1, and oscillation stage 1 is made of a lamp pump cavity 11 and is respectively arranged on the total reflection mirror 12 and the lamp pump cavity 11 both sides. The output mirror 13 is composed of an amplification stage 2 outside the output mirror 13, and the amplification stage 2 is composed of a coupling mirror 21 near the output mirror 13 and another lamp pump cavity 22.

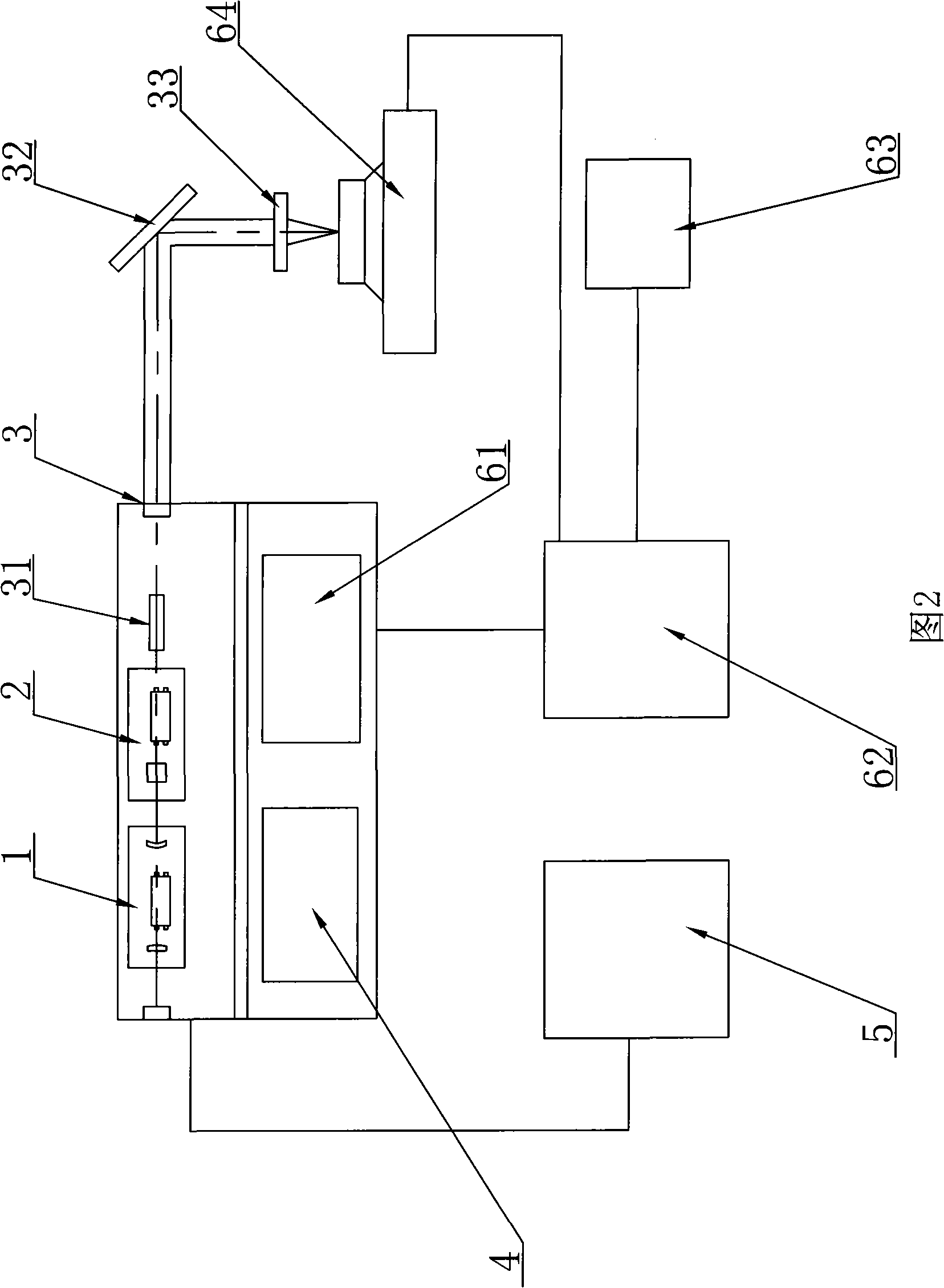

[0011] As shown in FIG. 2 , the laser with the above-mentioned structure is used on a laser cutting machine, and the laser cutting machine generally includes: an optical system, a power supply system 4 , a control system and a cooling system 5 . The power supply system 4 is a device that provides power for the laser cutting machine. The control system mainly includes: a control system 61, a numerical control device 62, an operation panel 63 and a processing table 64. The control sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com