Polylactic acid resin multilayer sheet and molded body made of same

A resin-like, polylactic acid technology, applied in the field of polylactic acid-based resin laminates, can solve the problems of non-existence, uninspired solutions, and no disclosure of heat resistance and plant-based impact resistance, and achieves excellent impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] As the preparation method of the above-mentioned polylactic acid-based resin, details will be described later, and a known polymerization method can be used, that is, a direct polymerization method from lactic acid, a ring-opening polymerization method via lactide, and the like can be used.

[0048] The melting point of the polylactic acid-based resin used in the present invention is not particularly limited, but is preferably 120°C or higher, more preferably 150°C or higher. The melting point of the above-mentioned polylactic acid resin can generally be improved by increasing the optical purity of the lactic acid component, and the polylactic acid resin with a melting point of 120° C. or higher can be obtained by containing 90 mol% to 100 mol% of the L-form, or 90 mol% to 100 mol% In addition, the polylactic acid resin with a melting point of 150° C. or higher can be obtained by containing 95 mol % to 100 mol % of the L form, or 95 mol % to 100 mol % of the D form.

[...

Embodiment 1

[0296] For layer A, use polylactic acid (P-1), polymethyl methacrylate (Q-4), and impact modifier (R-8) in a ratio of 93:2:5, and for layer B, Polylactic acid (P-1) and polymethyl methacrylate (Q-4) are supplied to independent respective vented twin-screw extruders at a ratio of 30:70, and the temperature of the die is set at The T-shaped die at 230°C is extruded together, and it is adhered to the casting drum cooled to 10°C by applying static electricity, and cooled and solidified to form B layer:A layer:B layer An unstretched sheet having a thickness ratio of 1:8:1 and an overall thickness of 0.5 mm.

[0297] The impact resistance of the obtained sheet was good, and the heat resistance of the molded article obtained from this sheet was also good, and the vegetation degree was also high.

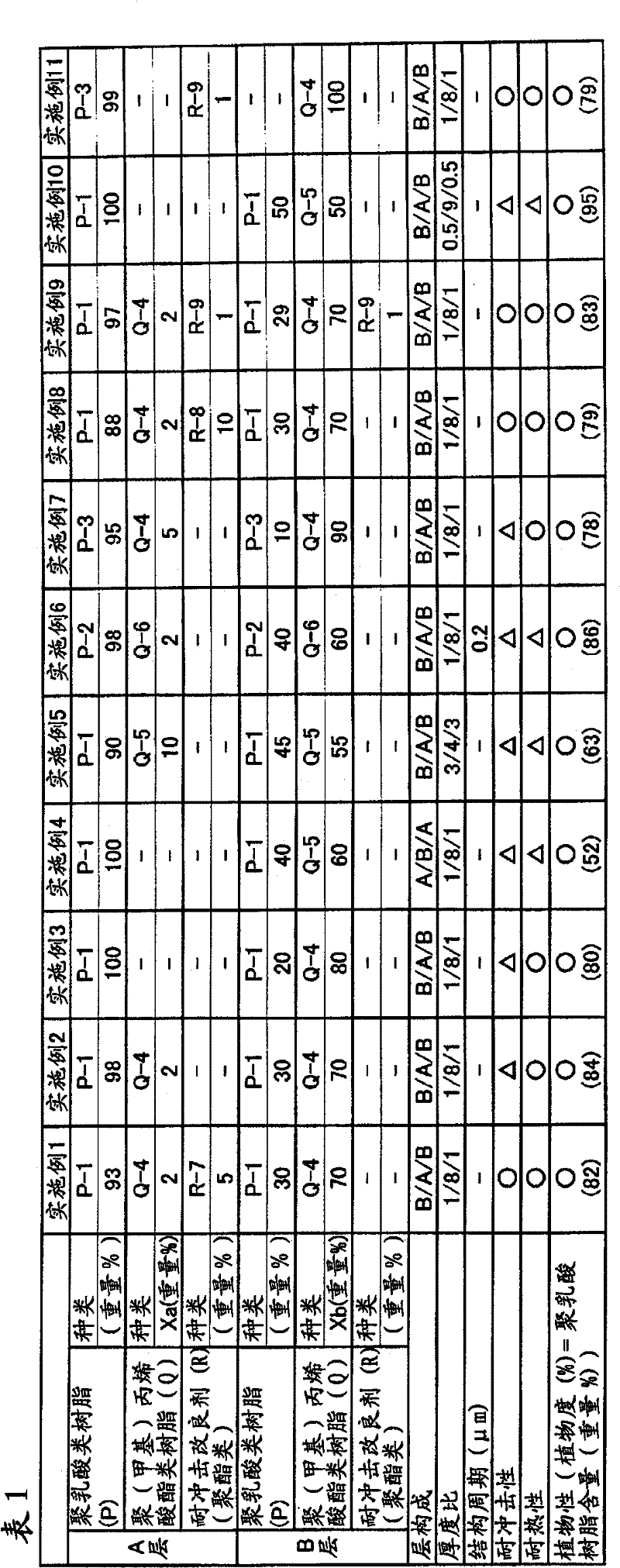

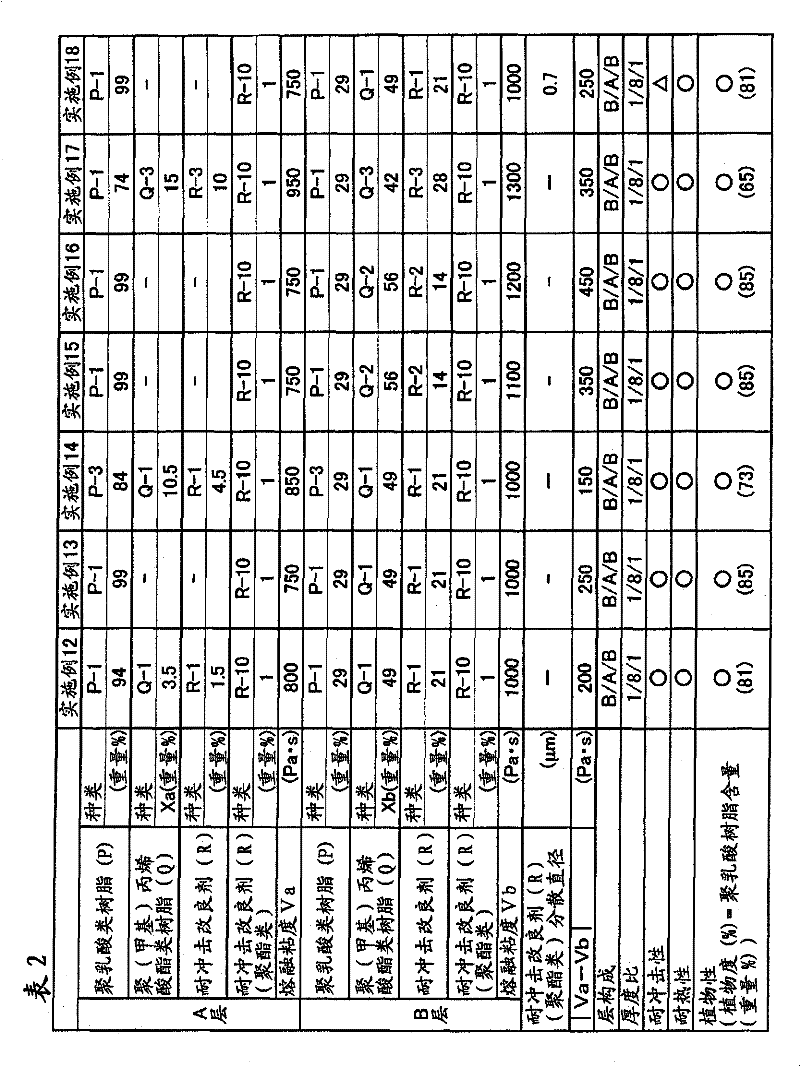

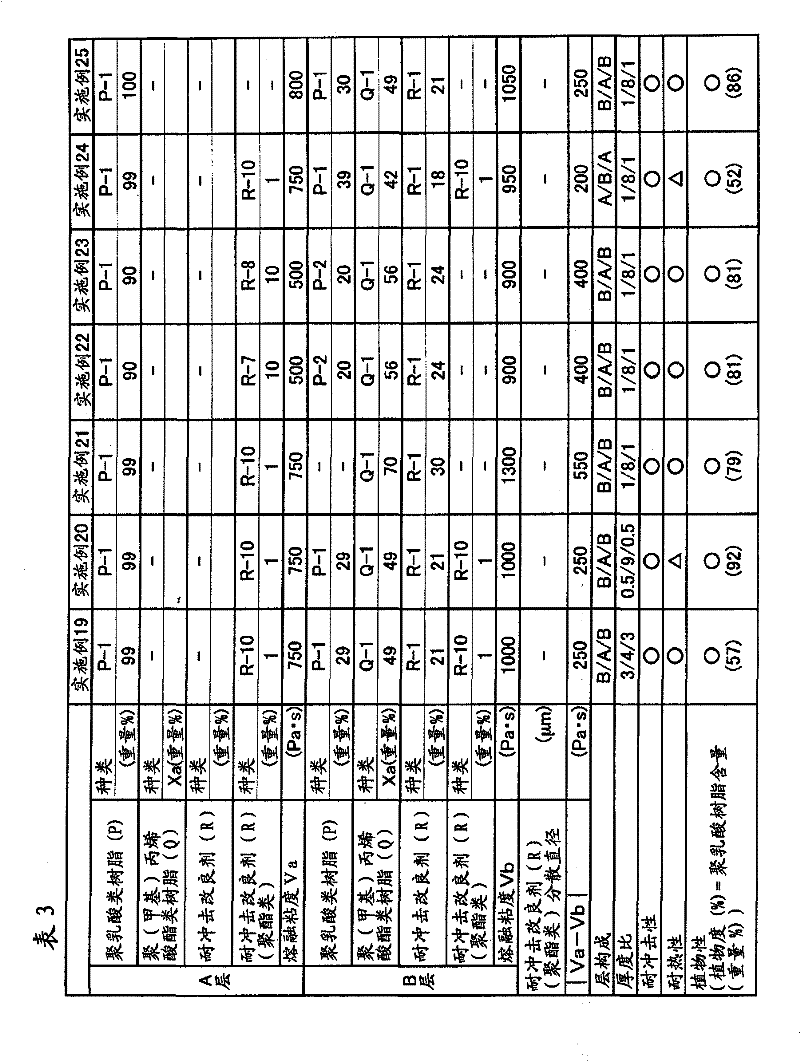

Embodiment 2~17、19~35

[0298] (Examples 2-17, 19-35, Comparative Examples 1-7)

[0299] In addition to changing the polylactic acid resin (P), poly(meth)acrylate resin (Q), impact modifier (R) constituting each layer, and the layer composition and thickness as shown in the table, Others were carried out in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com