Method for preparing bimalieimide resin modified cyanate preimpregnation material

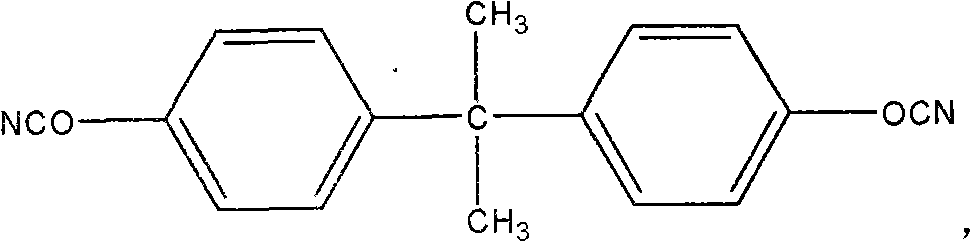

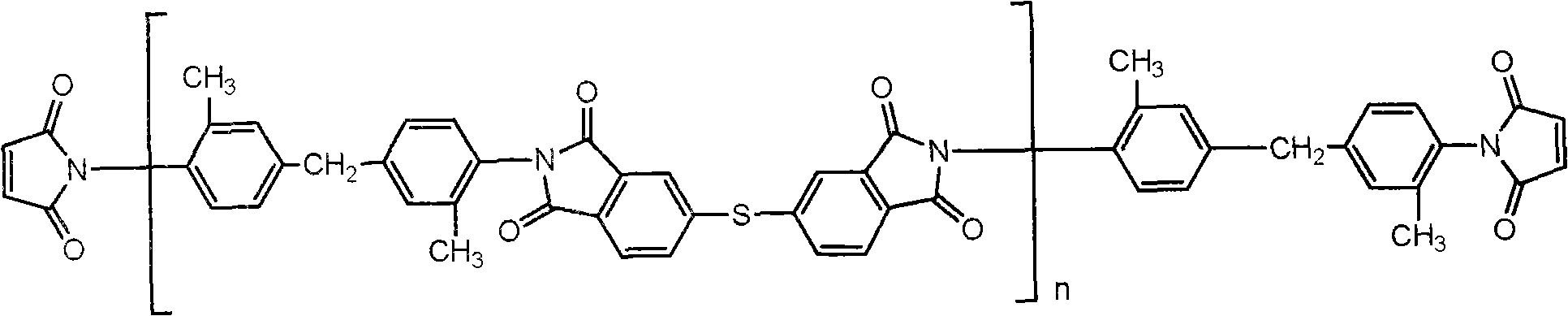

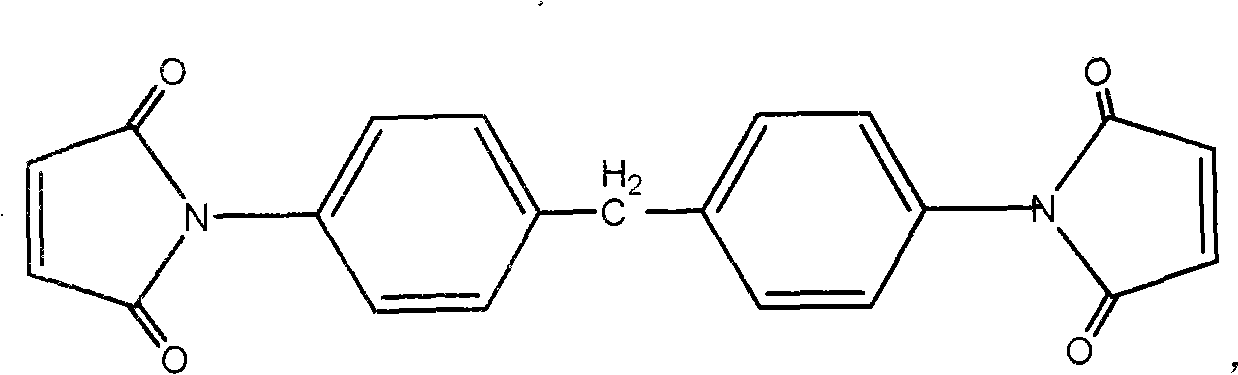

A technology of double horse resin and cyanate ester, which is applied in the field of preparation of double horse resin modified cyanate ester prepreg, can solve the problems of low molecular weight, high crosslinking density of BT resin, poor resin toughness, etc., and achieve high toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Take by weighing 30g of bisphenol A type cyanate ester (BCE) resin at room temperature, 70g of M1 resin in a reaction flask, add dioxane and ethylene glycol monomethyl ether with a volume ratio of 4:3:3 , ethylene glycol dimethyl ether mixed solvent 234ml, after refluxing for 5 minutes, a kind of bis-horse resin modified cyanate ester prepreg was obtained.

Embodiment 2

[0017] Example 2: Weigh 30 g of bisphenol A type cyanate ester (BCE) resin and 30 g of M1 resin in a reaction flask at room temperature, and add 140 ml of a mixed solvent of dioxane and ethylene glycol monomethyl ether in a volume ratio of 6:4 After reflux for 30 minutes, a bis-horse resin modified cyanate ester prepreg was obtained.

Embodiment 3

[0018] Example 3: Weigh 30 g of bisphenol A cyanate ester (BCE) resin and 3.33 g of M1 resin in a reaction flask at room temperature, and add a mixed solvent of dioxane and ethylene glycol dimethyl ether in a volume ratio of 5:5 78ml, after refluxing for 60 minutes, a kind of double horse resin modified cyanate ester prepreg was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com