Resetting and calibration of detector for visible and infrared composite light path light axis parallelism

A technology of parallel optical axis and complex light, which is applied in the field of optical detectors to achieve the effects of high detection accuracy and convenient installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] This embodiment introduces a method for installing, adjusting and calibrating an optical axis parallelism detector for a combined visible and infrared optical path. The specific steps are as follows:

[0024] (1) Coarse adjustment of the instrument;

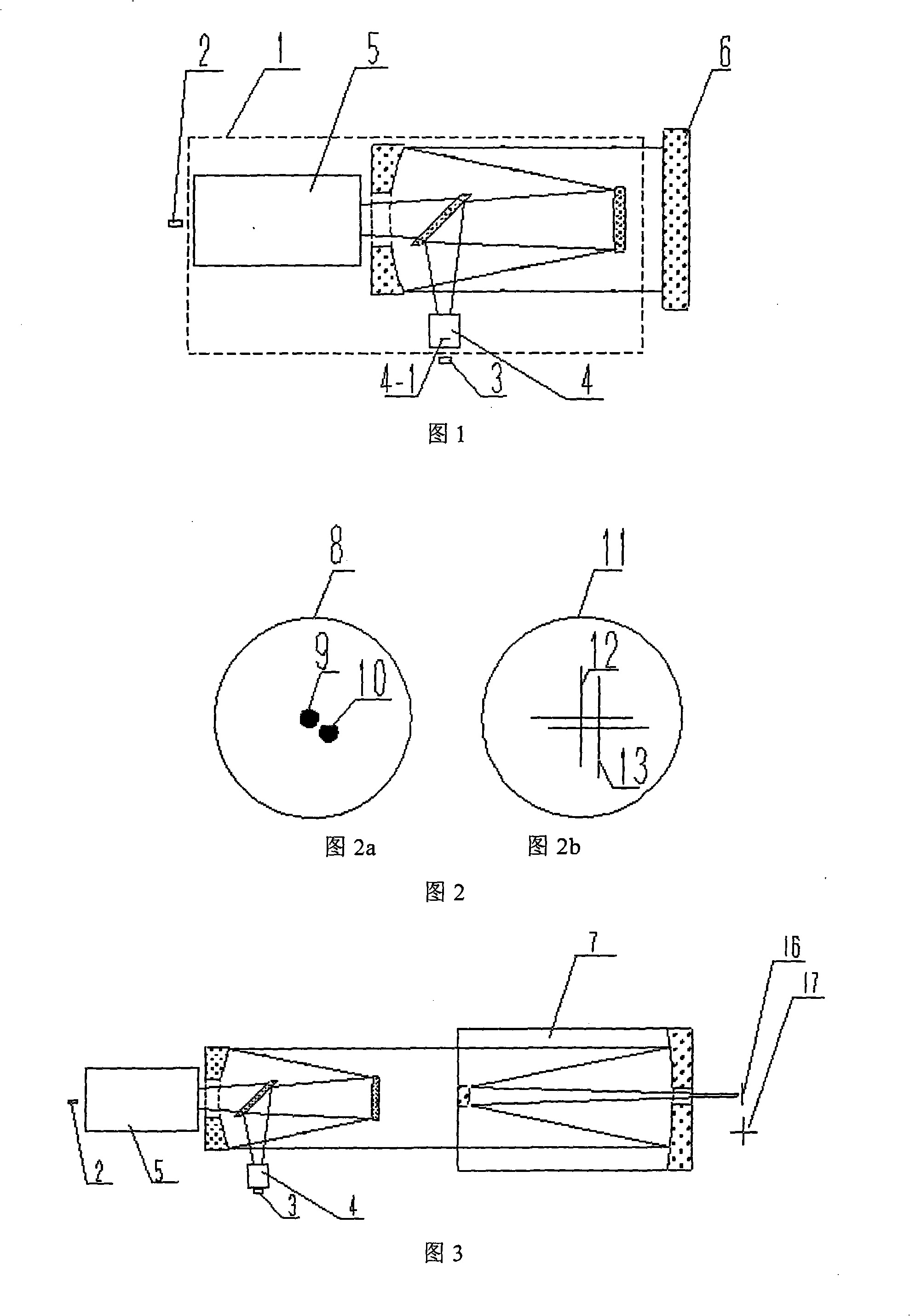

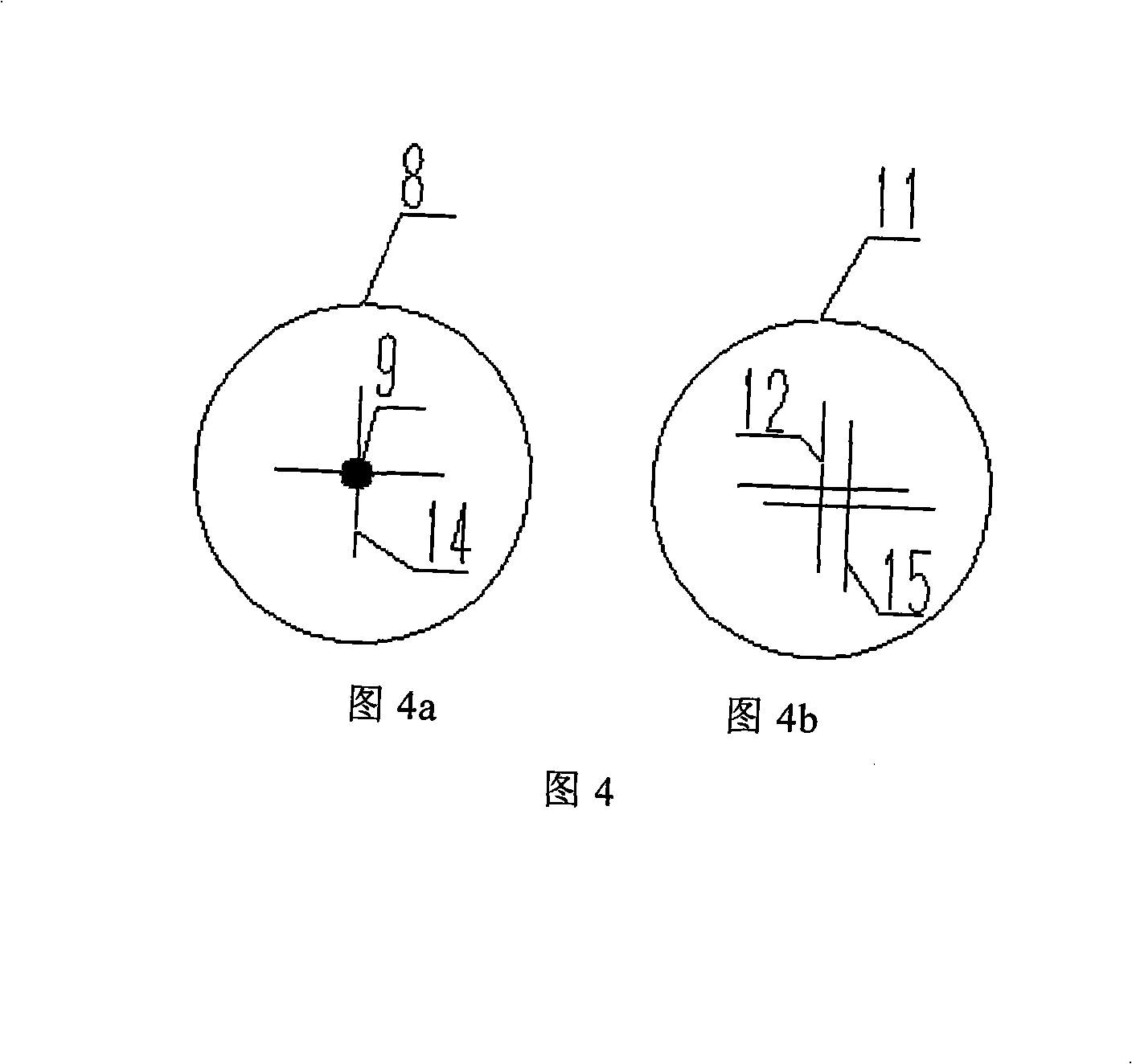

[0025] As shown in Figure 1, place a visible crosshair 4-1 on the focal plane of the visible light part 4 of the visible and infrared compound optical path optical axis parallelism detector 1, and then place a visible light CCD3; An infrared CCD2 is placed behind the focal plane of the infrared part 5 of the detector 1, and a standard flat mirror 6 is placed behind the visible and infrared compound optical path optical axis parallelism detector 1, and the inclination and pitch of the standard flat mirror 6 are adjusted so that the visible light CCD3 can See the image 12 of the outgoing v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fever temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com