Capillary pipe optical fibre light forceps and its manufacture method

A technology of optical fiber optical tweezers and a manufacturing method, applied in the field of optical tweezers, can solve problems such as low efficiency of manipulation and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

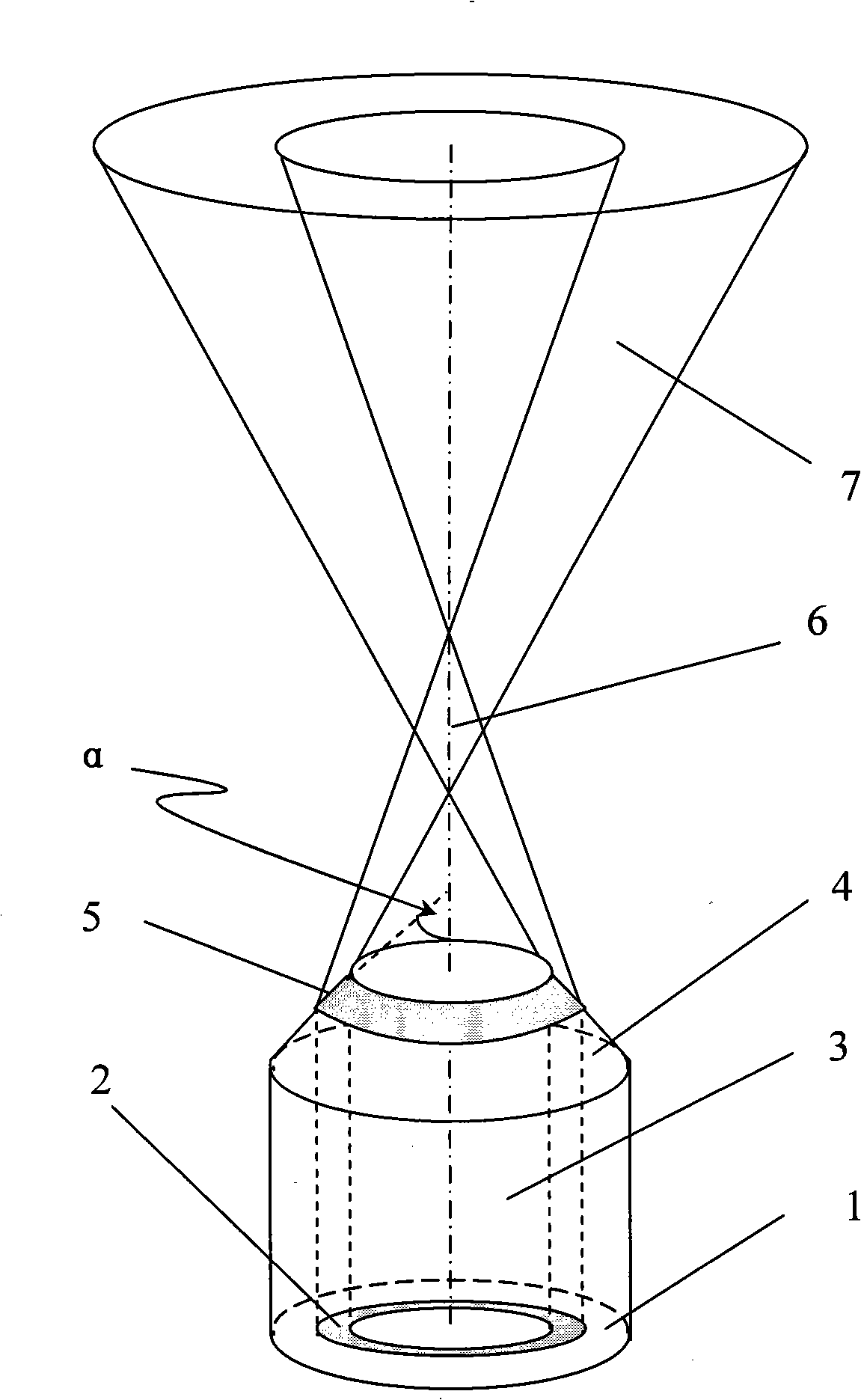

[0029] figure 2 An implementation method of the tapered fiber optical tweezers of the present invention is given. Its implementation process is as follows:

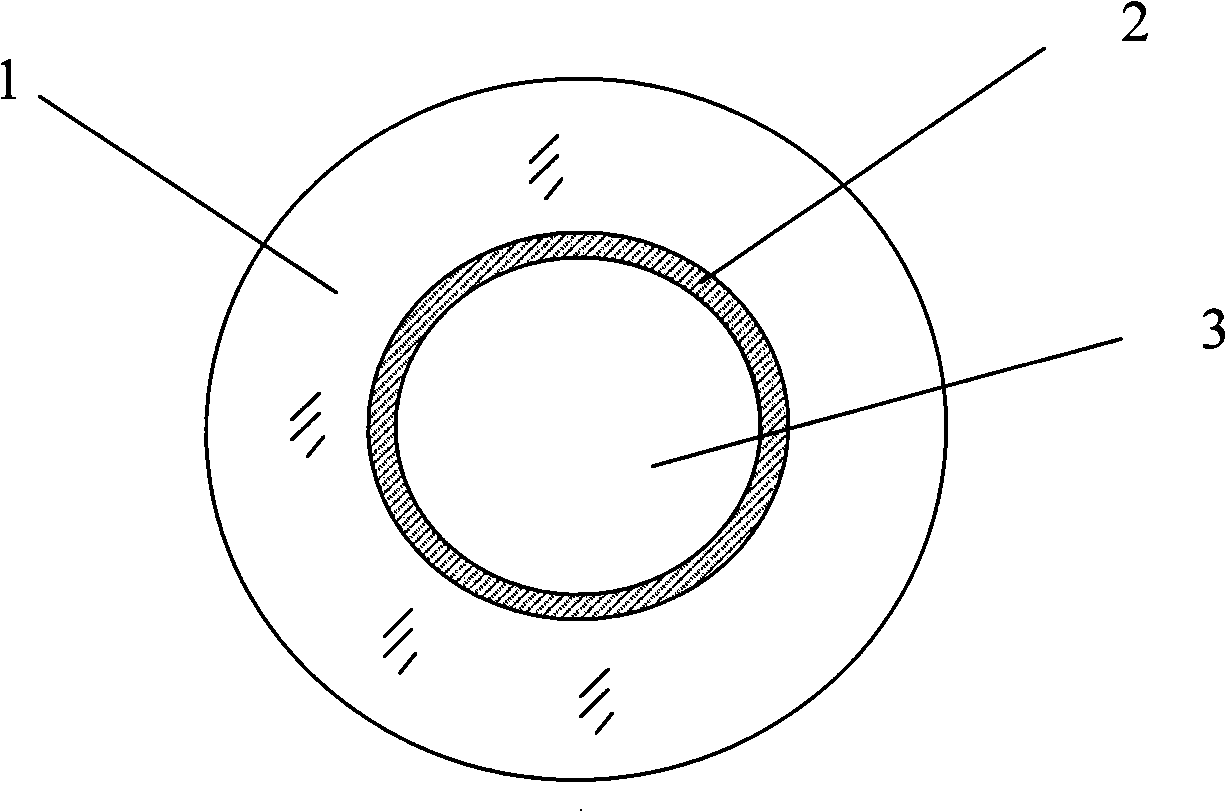

[0030] Step 1, Cone Grinding: Take a section Figure 1-a In the illustrated ring-core capillary fiber, the waveguide layer of the fiber is located on the inner wall of the capillary. With the aid of the bare fiber end grinding system, one end is ground into a figure 2 In the shape of the cone shown, in order to ensure that the outgoing light can form intersecting cone beams after being refracted by the cone surface, the half-cone angle α is controlled at π / 2-arcsin(n liquid / n core )core =1.4868, cladding refractive index n cladding =1.4571, and the liquid refractive index n where the fiber optical tweezers are located water = 1.333, the range of the half-cone angle should be controlled between 26.3° and 80°.

[0031] Step 2, cone polishing: put the above-mentioned ground optical fiber cone in the bare optical fi...

Embodiment ( 2

[0036] image 3 Another implementation method of optical tweezers with a ring-core capillary tube provided by the present invention is given. Its implementation process is as follows:

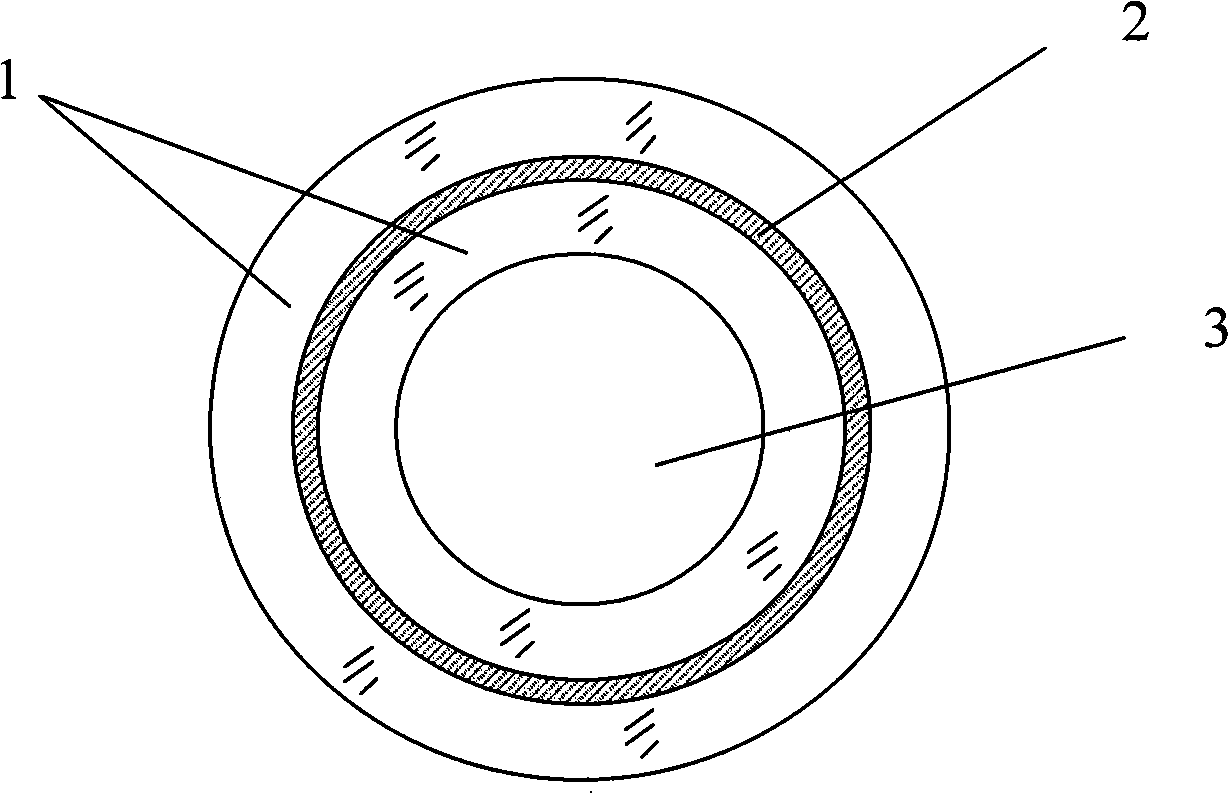

[0037] Step 1, Cone Grinding: Take a section Figure 1-b The ring-core capillary fiber shown has one end ground to a shape such as image 3 In the shape of the frustum of the cone shown, in order to ensure that the outgoing light can form total internal reflection light after passing through the conical surface 4 of the frustum of the cone, and refracted by the top surface of the frustum of the cone to form intersecting conical beams, the half-cone angle α should be controlled at 0liquid / n core )In the range. For the core refractive index n core =1.4868, cladding refractive index n cladding =1.4571, and the liquid refractive index n where the fiber optical tweezers are located water = 1.333, the range of the half-cone angle α should be controlled between 10° and 26.3°.

[0038] Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com