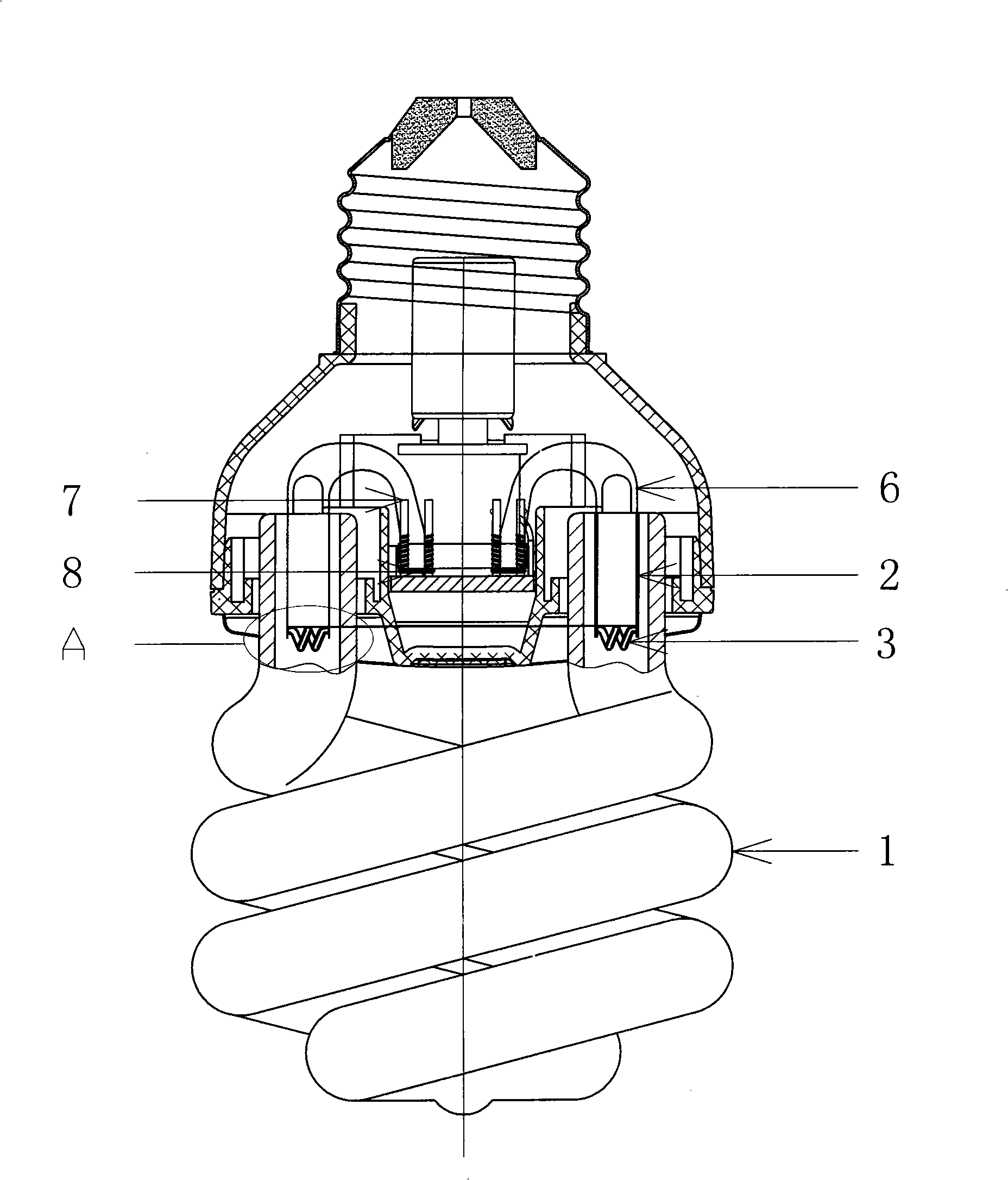

Cold-starting low-voltage fluorescent lamp

A fluorescent lamp and cold start technology, applied in discharge lamps, gas discharge lamps, electrical components, etc., can solve problems such as increased sputtering of electronic powder, decreased switching times and life, and decreased filament temperature, so as to reduce production costs and improve competition. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

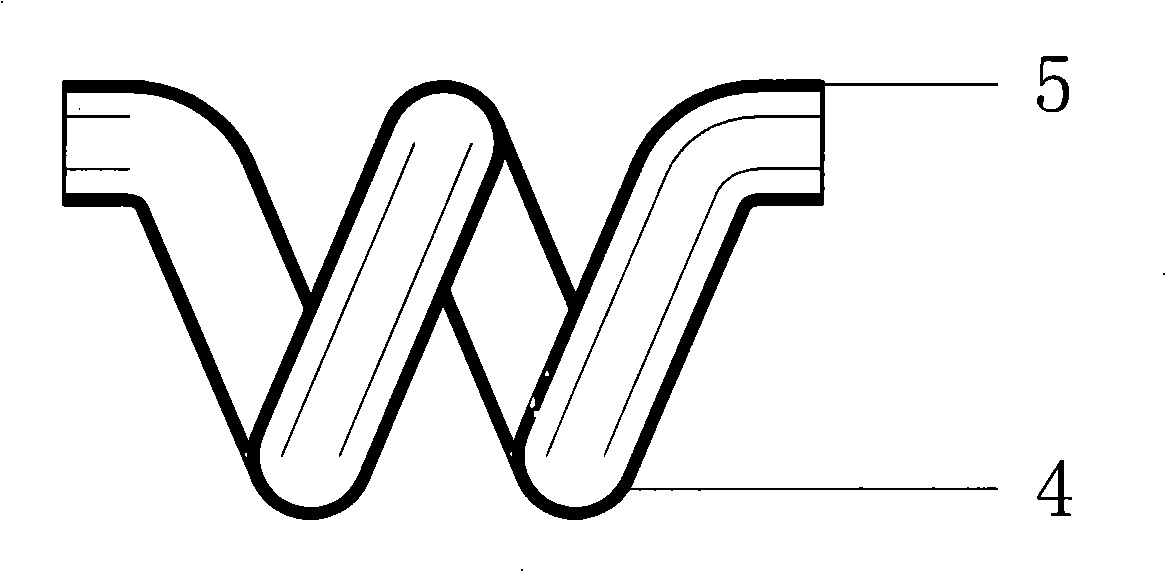

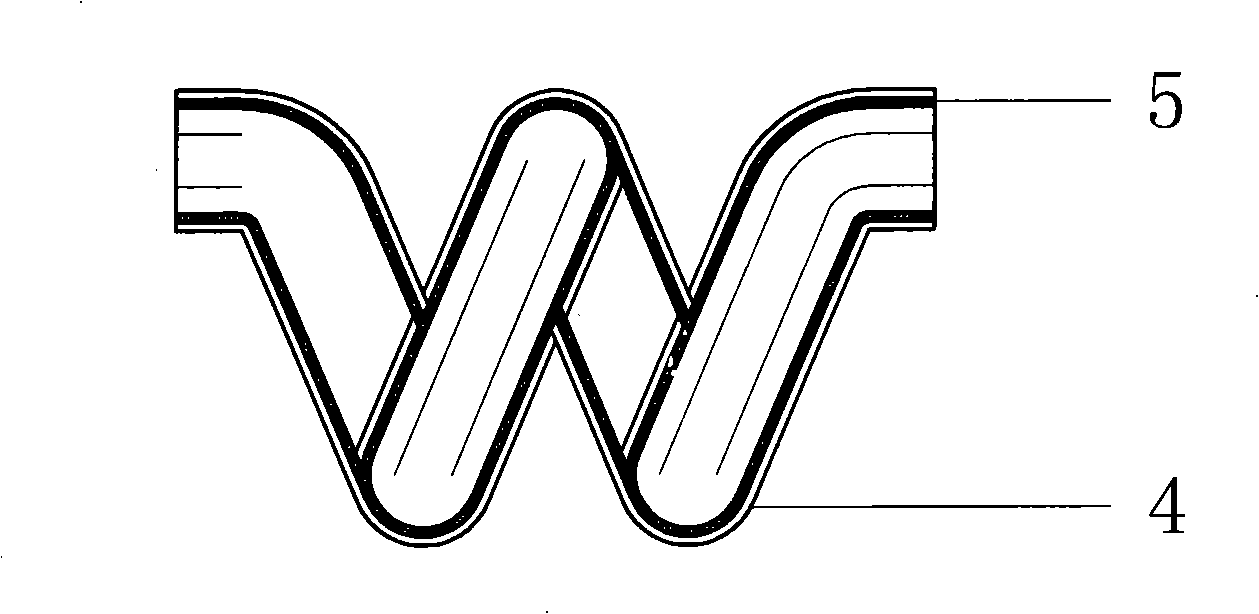

Embodiment 1

[0020] The fluorescent tube of the present invention is improved on the prior art. First, the rare earth oxide slurry is prepared, and 10 grams of yttrium oxide, 20 grams of zirconia, 70 grams of aluminum oxide and deionized water are mixed into 1000 ml of slurry, and the filament First apply electronic powder on the main part in the middle, and then apply rare earth oxide slurry on the wire feet at both ends, then take the baked powder tube and the filament dipped in electronic powder, and seal and discharge according to the normal process. Gas and post-treatment, made of 13W energy-saving lamps. The average initial luminous flux is 960Lm, the average switching times is 12,000 times, and the service life reaches 15,000 hours.

Embodiment 2

[0022] First prepare the rare earth oxide slurry, take 50 grams of yttrium oxide, 30 grams of zirconia, 20 grams of aluminum oxide and deionized water to prepare a 1000ml slurry, first coat the filament with electronic powder on the main part in the middle, and then The end wire foot part is coated with rare earth oxide powder, and then the baked powder tube and the filament coated with electronic powder are taken, and the sealing, exhaust and post-treatment are carried out according to the normal process to make a 23W energy-saving lamp tube. The average initial luminous flux is 1650Lm, the average switching times is 13,000 times, and the service life reaches 15,000 hours.

Embodiment 3

[0024] First prepare the rare earth oxide slurry, take 20 grams of europium oxide, 40 grams of zirconia, 40 grams of aluminum oxide and deionized water to prepare a 1000ml slurry, first coat the filament with electronic powder on the main part in the middle, and then The end wire foot part is coated with rare earth oxide powder, and then the baked powder tube and the filament coated with electronic powder are taken, and the sealing, exhaust and post-treatment are carried out according to the normal process to make a 42W energy-saving lamp tube. The average initial luminous flux is 2900Lm, the average switching times is 12000 times, and the service life reaches 15000 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com