Encapsulation construction of LED

A light-emitting diode and packaging structure technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of inability to meet the miniaturized light-emitting diode packaging structure, poor heat resistance, unfavorable light reflection, etc., and achieve excellent reflection and durability. Effects of thermal characteristics, prolonging service life, and improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A light emitting diode packaging structure according to a preferred embodiment of the present invention will be described below with reference to related drawings.

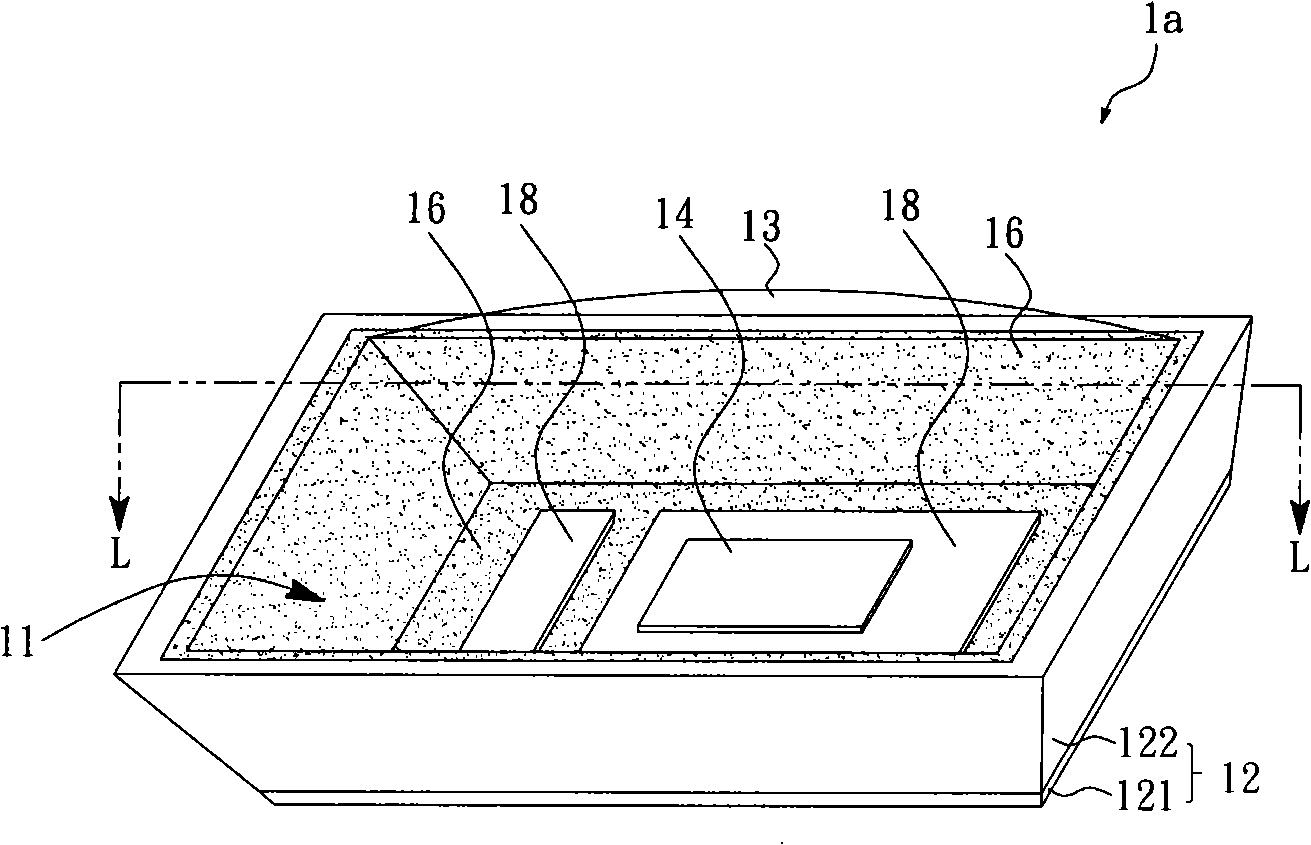

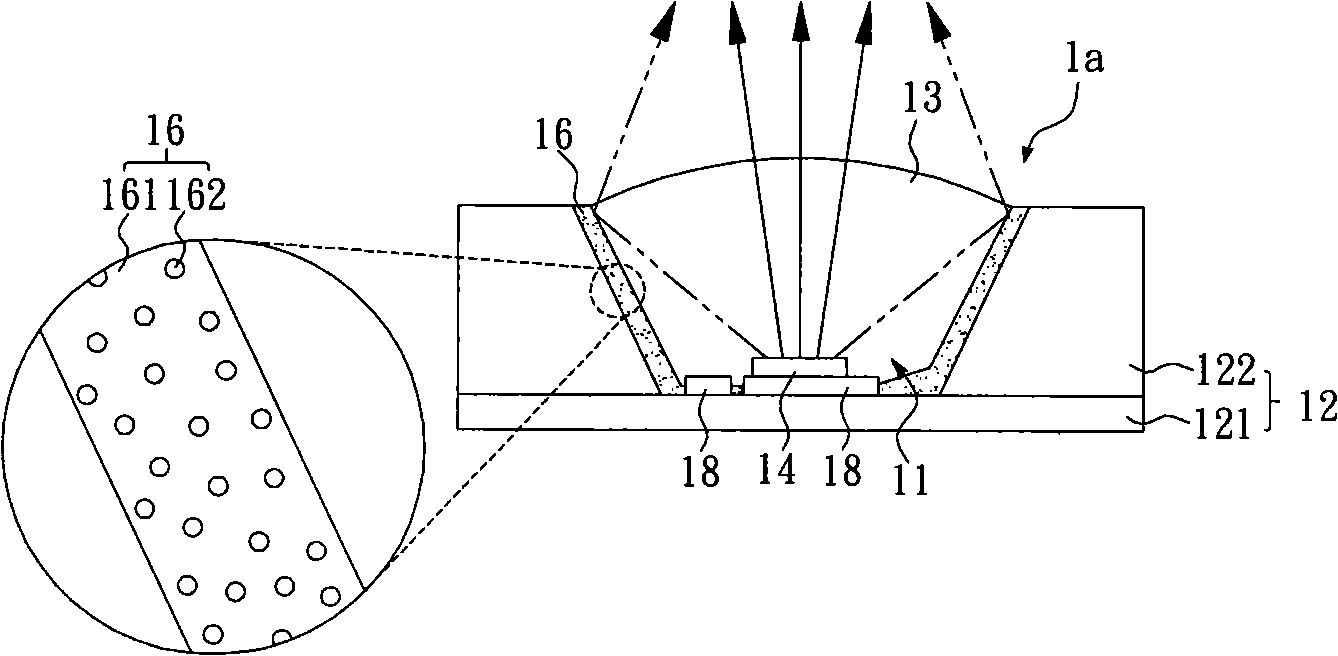

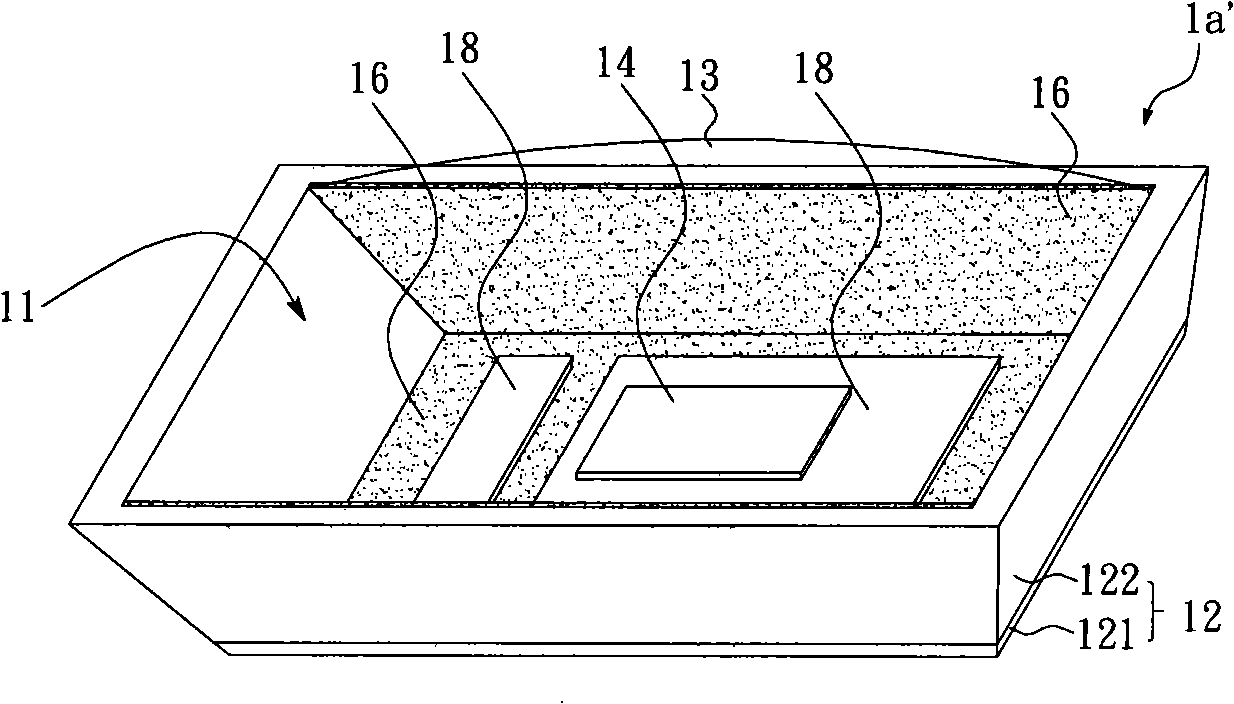

[0034] First, please also refer to Figure 1A , Figure 1B and Figure 1C shown, where Figure 1A is a perspective view of the LED packaging structure, and Figure 1B then along Figure 1A A cross-sectional view of the light-emitting diode package structure at the mid-section line L, Figure 1C then Figure 1A Another perspective view of .

[0035] First, according to Figure 1A and Figure 1B It can be seen that the LED package structure 1 a shown in the figure includes a carrying unit 12 , a LED chip 14 , a composite material layer 16 and a reflective electrode 18 . A reflective electrode 18 is set between the carrying unit 12 and the LED chip 14, in other words, the reflective electrode 18 is set on the carrying unit 12, and the light emitting diode chip 14 is located on the reflective electrode 18...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com