Oil gas recovery method

A recovery method, oil and gas technology, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve problems such as complicated processes and inability to be used directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

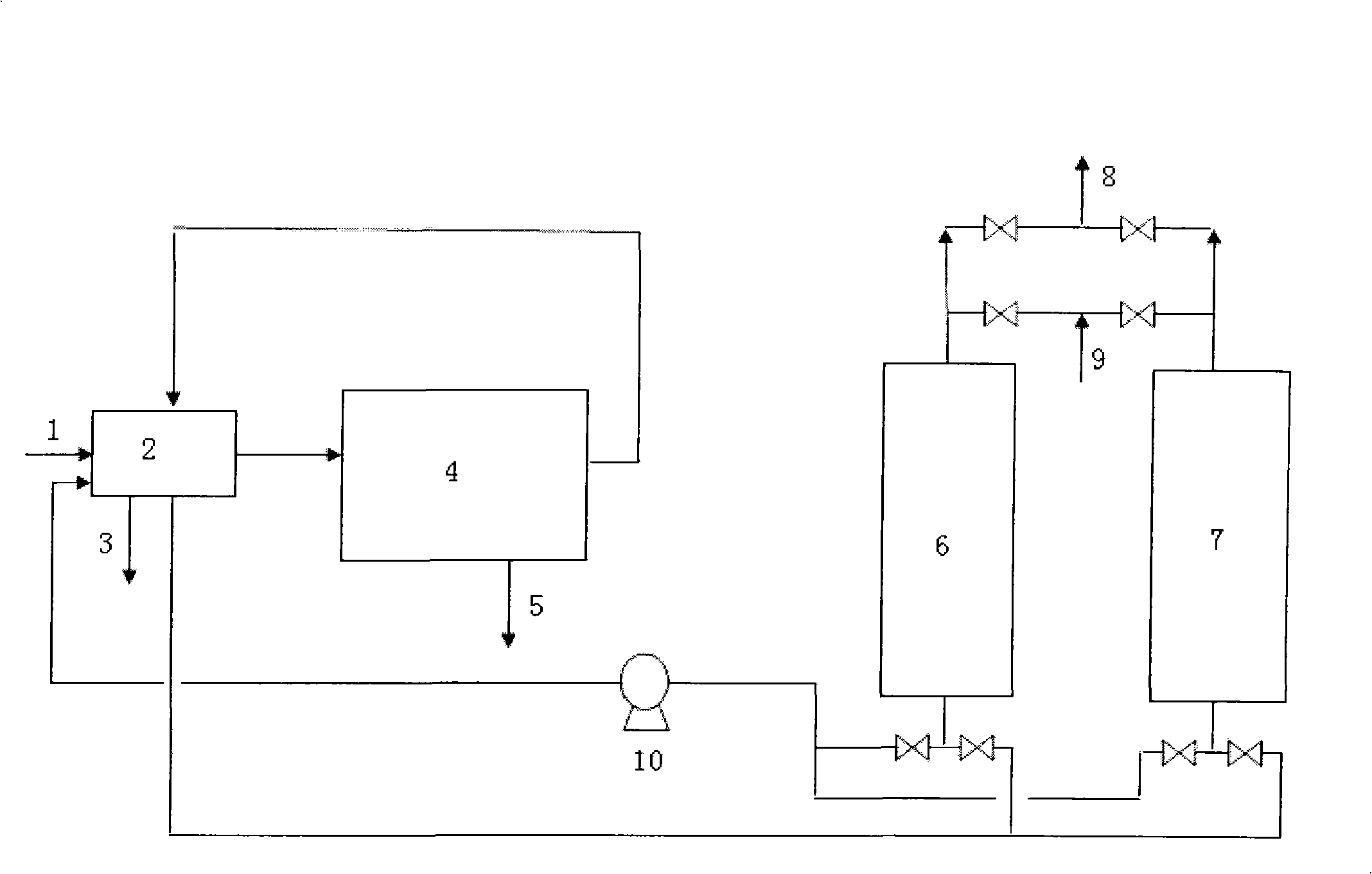

Image

Examples

Embodiment 1

[0034] In this example, condensation-adsorption is used to treat benzene-containing gas at a temperature of 50°C and a concentration of 3000 mg / m 3 , mechanical refrigeration method, the adsorbent is activated carbon, the oil gas temperature at the inlet of the condenser is 8°C, the condensation temperature is -55°C, the oil gas temperature at the inlet of the adsorption tower is -5°C, and the adsorption space velocity is 1000h -1 , the gas velocity is 0.3m / s, and the outlet temperature of the adsorption tower is 10°C. After treatment by this process, the concentration of benzene in the outlet gas is less than 10mg / m 3 , The recovery rate is 98% (mass).

Embodiment 2

[0036] In this embodiment, the exhaust gas is 20% (volume) oil gas, the temperature is 35°C, the oil gas temperature at the inlet of the condenser is -5°C, the condensation method is mechanical refrigeration, and the condensation temperature is -75°C. The adsorbent adopts carbon molecular sieve, the oil gas temperature at the inlet of the adsorption tower is -15°C, and the adsorption space velocity is 2000h -1 , the gas velocity is 0.2m / s, and the outlet temperature of the adsorption tower is 5°C. After this process, the outlet oil and gas concentration is less than 10mg / m 3 , Recovery > 99.9% (mass).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com