High-voltage panel type grinding equipment and its processing method

A grinding and equipment technology, applied in cocoa, grain processing, food science, etc., to achieve the effect of super continuous extrusion, strong adaptability and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

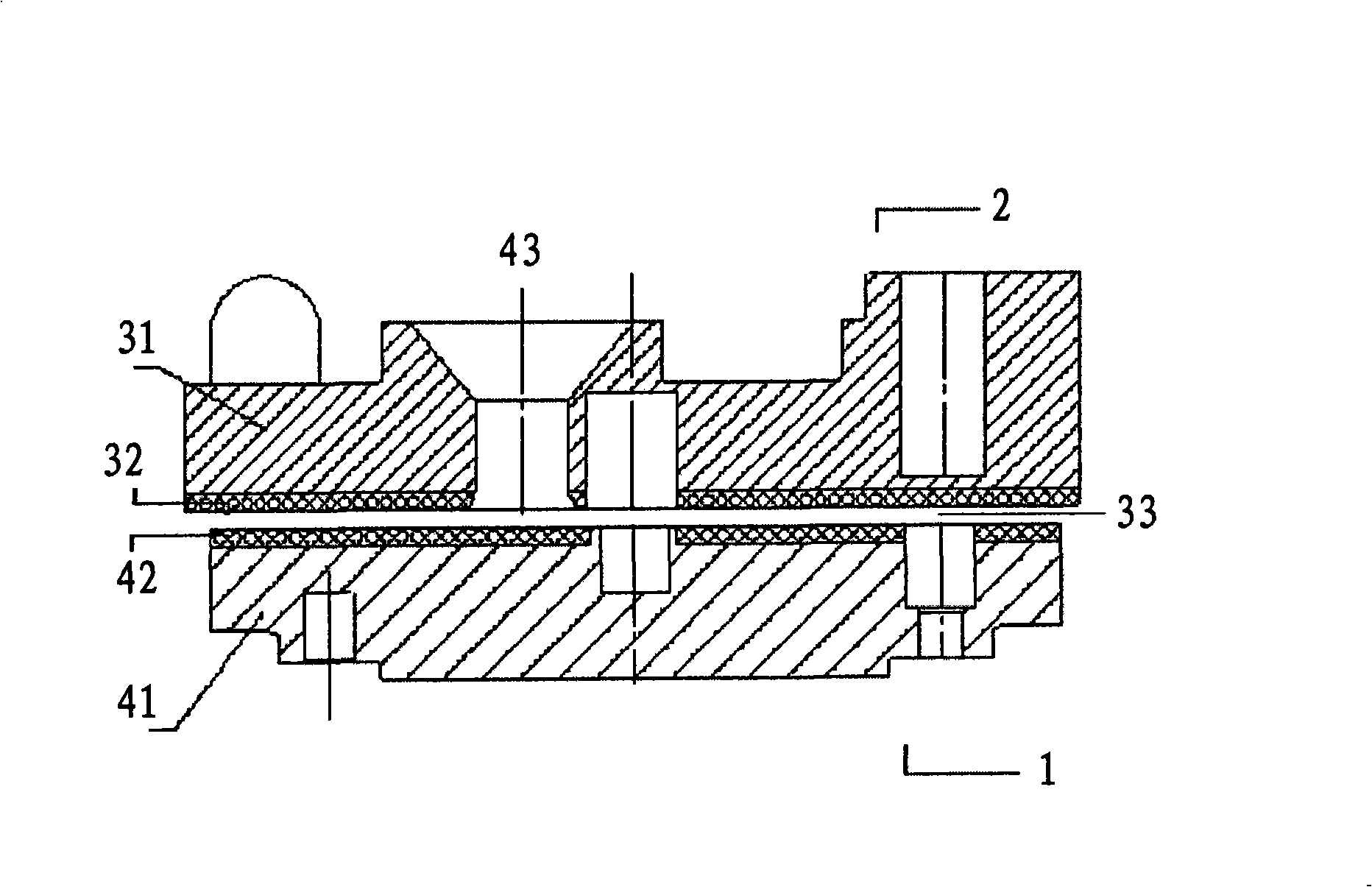

[0085] see figure 2 shown. It is the first preferred embodiment of the grinding disc of the present invention, a schematic cross-sectional view of the grinding disc of the high-pressure disc grinding equipment. It includes a rotating grinder 1 and a fixed grinder 2 . The fixed grinding disc 2 includes an upper base body 31 , the lower surface of which is an upper grinding layer 32 ; The rotating grinding disc 1 includes a lower base 41 , the upper surface of which is a lower grinding layer 42 , and the rotating grinding disc 1 and the fixed grinding disc 2 are placed horizontally on top of each other.

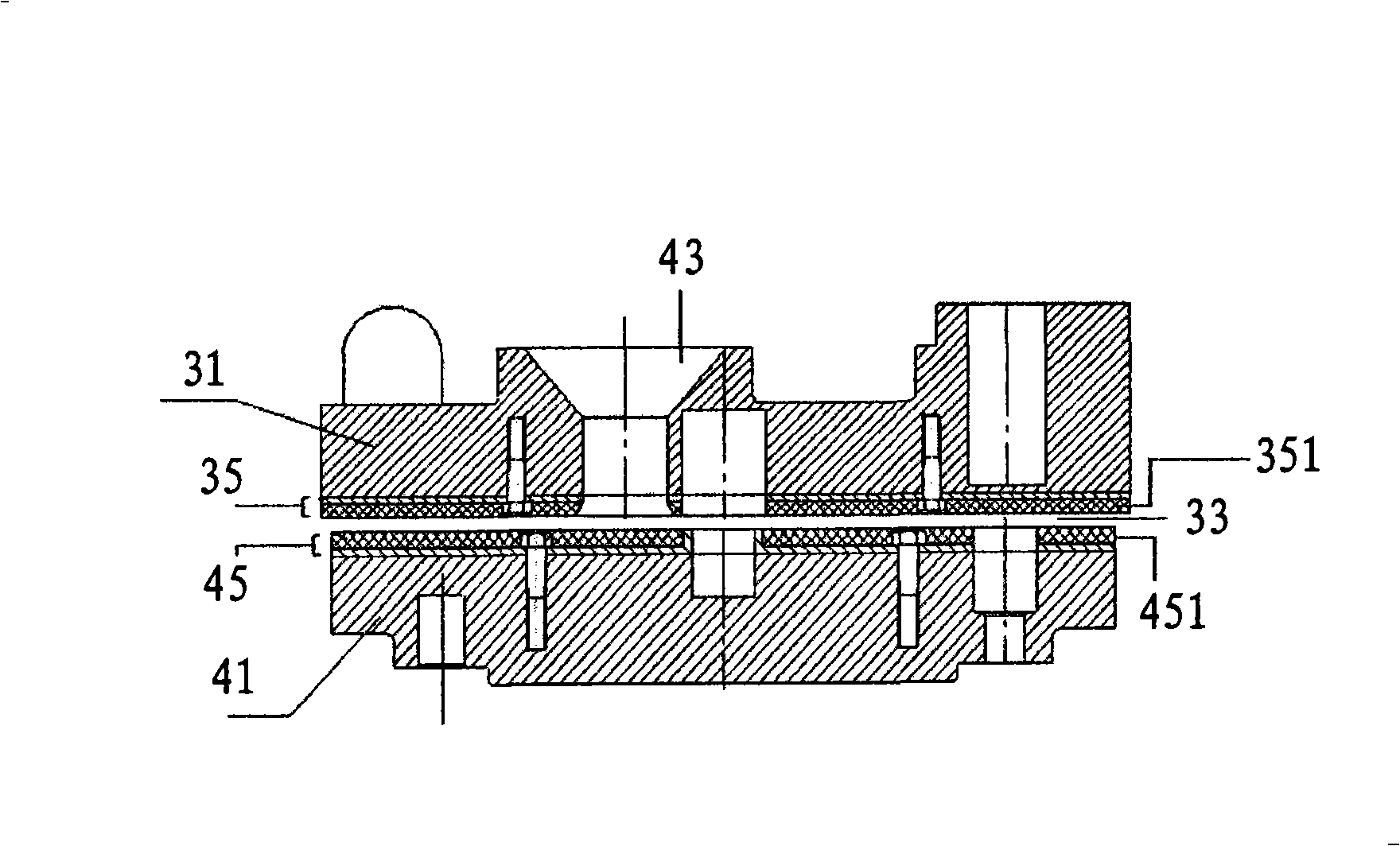

[0086] see image 3 shown. It is the second preferred embodiment of the grinding disc of the present invention, a schematic cross-sectional view of the grinding disc of the high-pressure disc grinding equipment. This embodiment includes a rotating grinder 1 and a fixed grinder 2 . The fixed grinding disc 2 includes an upper base body 31 and an upper grinding sheet 35, on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com