Method for manufacturing super-flat compact type chain vertical ring

A manufacturing method and compact technology, applied in the direction of metal chains, etc., can solve the problems of inconsistent heating temperature of the blank, long working hours, forging defects on the surface of the chain ring, etc., to achieve good mechanical properties and use effects, reduce manufacturing costs, and improve mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

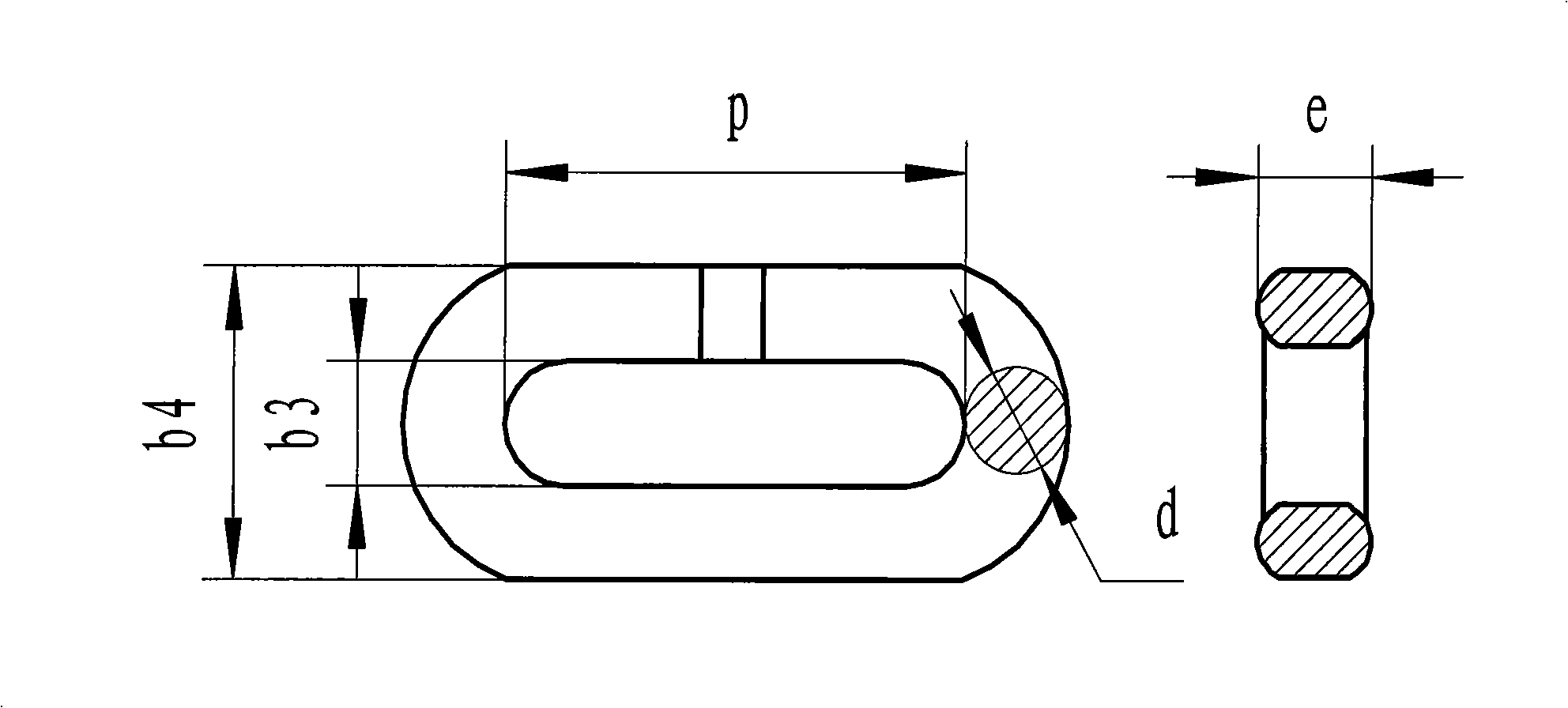

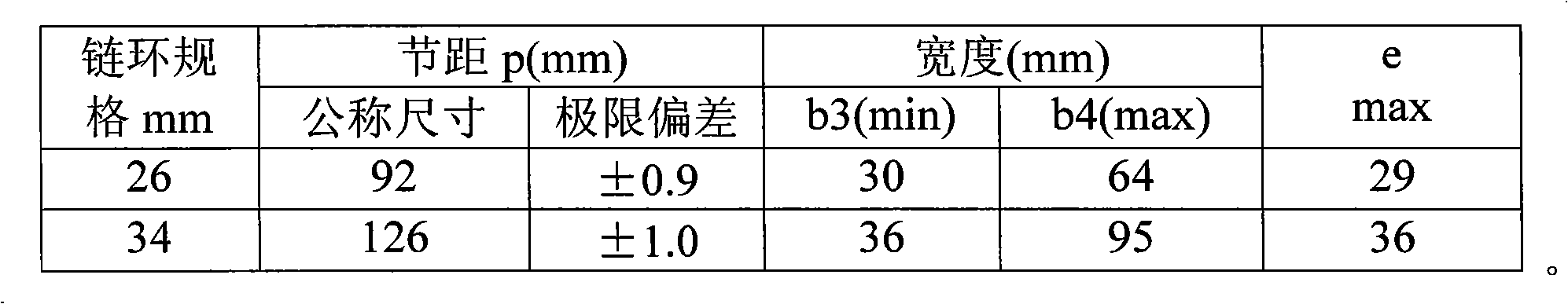

[0021] The following takes the Φ26×92 compact chain as an example to illustrate the process of manufacturing compact chains:

[0022] (1) Use a press machine to crush the hot-rolled material 23MnNiMoCr54 chain steel Φ26mm into a 296mm long material rod; place the material rod on the chain tire of the press workbench, and bend it into a large V-shaped mouth. Then press the large V-shaped mouth of the chain ring into a small V-shaped mouth in the joint tire of the press workbench; transfer the compiled chain link to the flash butt welding machine to complete the welding process; put the pressure immediately after removing the thorn Insert the heart tire into the bent and formed chain ring and place it on the special mold that ensures the arc of the chain ring after pressing, apply pressure, and flatten the amount of 16mm. Plane milling removes 3mm to reach the required size, and completes the super flat ring production;

[0023] (2), connect the super flat ring and the welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com