Method for preparing 7 alpha-bromo-sterides

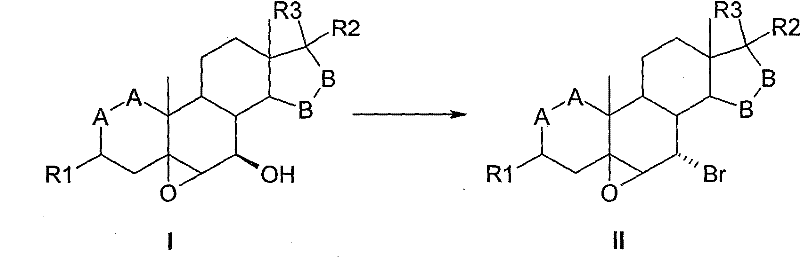

A technology of steroidal compounds and bromination, applied in the field of preparation of 7α-bromosteroidal compounds, can solve the problems of large amount of use and increase, and achieve the effects of simple operation, environmentally friendly process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

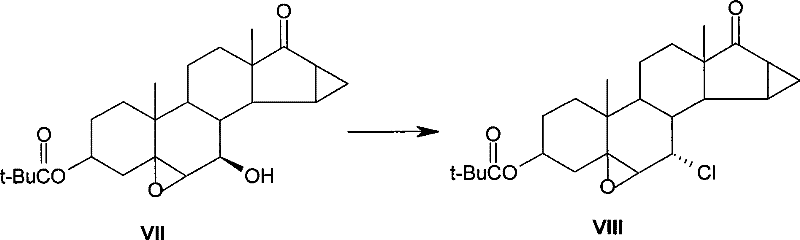

Embodiment 1

[0034] Under the protection of argon, put 10g of 3β-pivaloyloxy-5,6β-epoxy-7β-hydroxy-15β,16β-methylene-androst-17-one into the reaction flask and add 20ml of dichloromethane 20ml of pyridine, and pyridine, keep the temperature at 25℃, add 11.8g of triphenylphosphine after dissolving, dilute 1.3ml of liquid bromine with 5ml of dichloromethane and add it dropwise to the reaction flask within 1 hour. The reaction is stirred for about 2 hours.

[0035] The reaction was followed by TLC (developer: cyclohexane: ethyl acetate = 1:4).

[0036] After the reaction, water was added to terminate the reaction, the organic phase was extracted and separated, and the organic phase was washed twice with water. Combine all the aqueous phases and back extract with dichloromethane. Combine all organic phases and dry with anhydrous sodium sulfate for 30 minutes. Concentrate to dryness, add methanol twice, and concentrate to remove residual dichloromethane. Add methanol to the residue for beating. ...

Embodiment 2

[0038] Under the protection of argon, put 10g of 3β-pivaloyloxy-5,6β-epoxy-7β-hydroxy-15β,16β-methylene-androst-17-one into the reaction flask and add 20ml of dichloromethane 20ml of pyridine, and pyridine, the temperature is kept at 25℃, after dissolving, add 8.2g of triphenylphosphine, dilute 1.5ml of bromine with 5ml of dichloromethane and add it dropwise to the reaction flask within 1 hour. The reaction is stirred for about 4 hours.

[0039] The post-reaction treatment is the same as in Example 1.

[0040] After drying, the product 3β-pivaloyloxy-5,6β-epoxy-7α-bromo-15β,16β-methylene-androst-17-one is 9.6g, the yield is 84%, and the purity by HPLC is 92 %.

Embodiment 3

[0042] Under the protection of argon, put 10g of 3β-pivaloyloxy-5,6β-epoxy-7β-hydroxy-15β,16β-methylene-androst-17-one into the reaction flask, and add 25ml of dichloromethane , And pyridine 25ml, keep the temperature at 20℃, add 14.5g of triphenylphosphine after dissolving, dilute 2.0ml of bromine with 6ml of dichloromethane, add dropwise to the reaction flask within 1 hour, after dripping The reaction is stirred for about 2 hours.

[0043] The post-reaction treatment is the same as in Example 1.

[0044] After drying, the product 3β-pivaloyloxy-5,6β-epoxy-7α-bromo-15β,16β-methylene-androst-17-one 8.1g, the yield is 70%, and the purity by HPLC is 90 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com