Dewaxing and sintering integrated technique for large product of hard alloy

A technology for cemented carbide and large products, which is applied in the field of preparation of large cemented carbide products by the integrated process of dewaxing and sintering, which can solve the problems of insufficient control precision of the carbon content of the product, and achieve dewaxing efficiency, effective removal, and operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

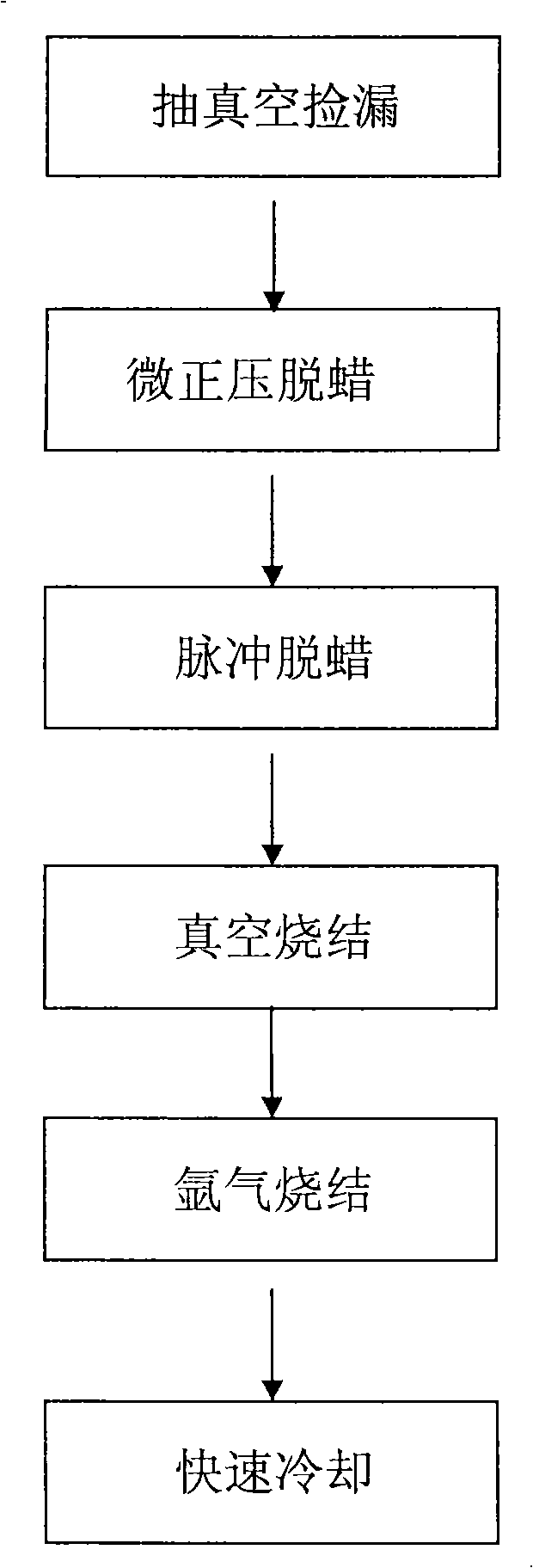

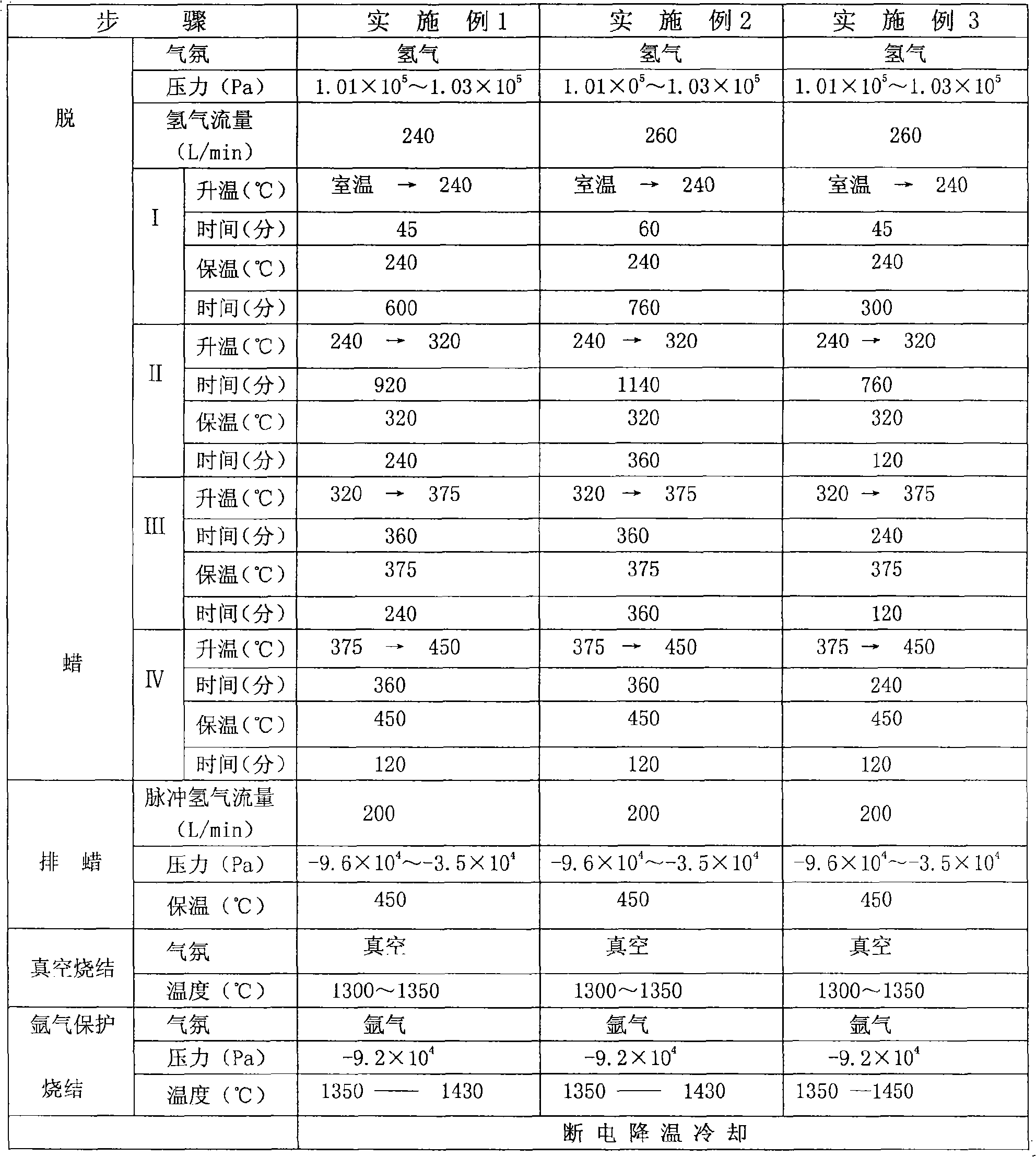

[0015] Embodiment 1 is to prepare φ 130mm cemented carbide top hammer, embodiment 2 is to prepare φ 160mm cemented carbide top hammer, and embodiment 3 is to prepare φ 216 (outer diameter), φ 160 (inner diameter), 72 (height) mm cemented carbide roll . The same process steps and process conditions adopted by the three embodiments are as follows, and the different process control parameters adopted by the three embodiments are shown in Table 1.

[0016] Since the dewaxing and sintering integrated process of the present invention adopts a hydrogen positive pressure atmosphere during the dewaxing process, in order to ensure safety, the furnace and the dewaxing pipeline are evacuated in advance, and leak detection is performed by a pressure rise method. After passing the leak detection, first fill the furnace with argon, and then replace the argon in the furnace with hydrogen. The hydrogen used is preferably hydrogen with a dew point ≥ -45°C, and the hydrogen pressure in the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com