Turbomachine rotor assembly

A turbine and rotor technology, applied to engine components, pump components, mechanical equipment, etc., can solve problems that affect the service life of turbines and support surface wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

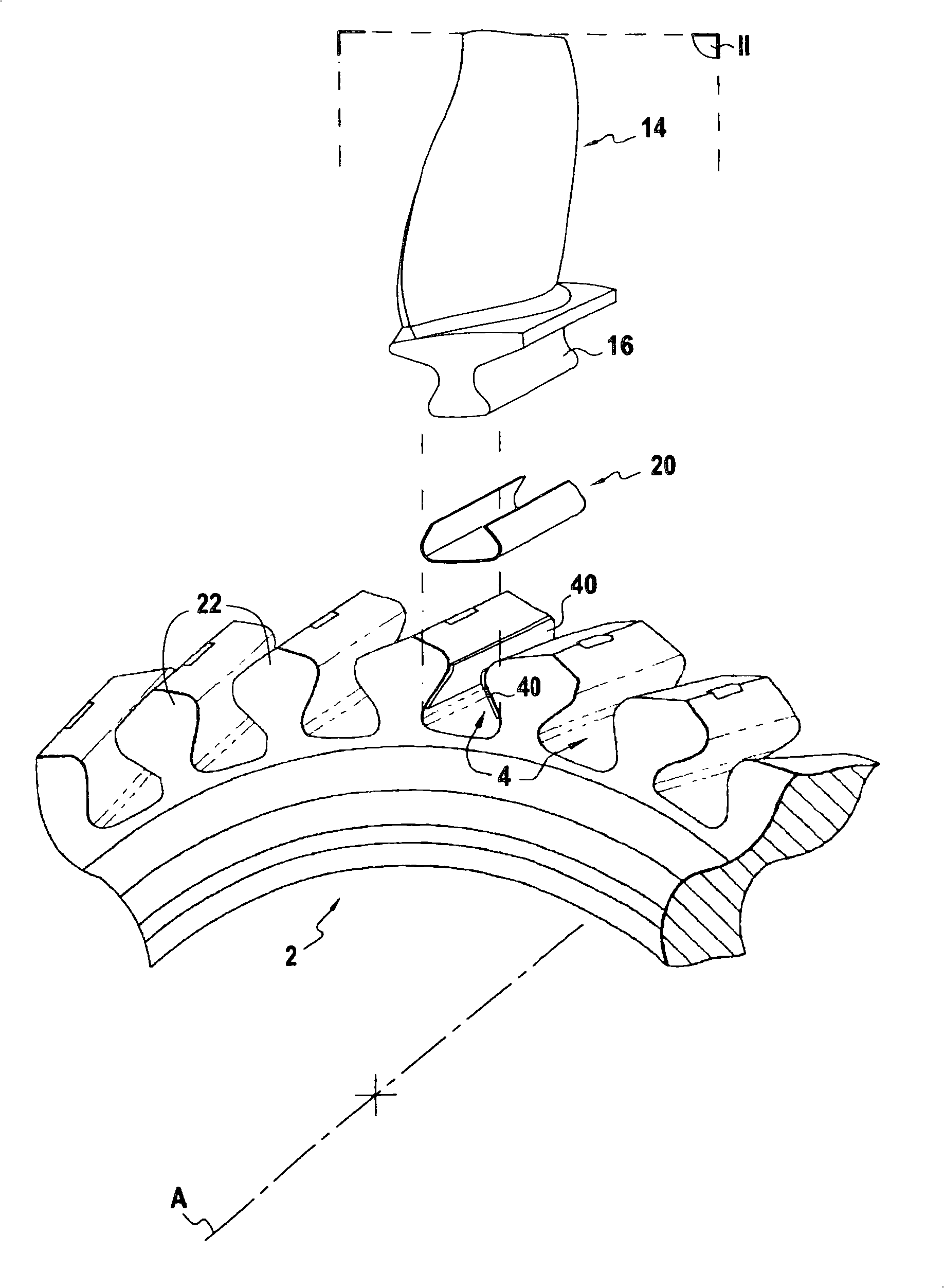

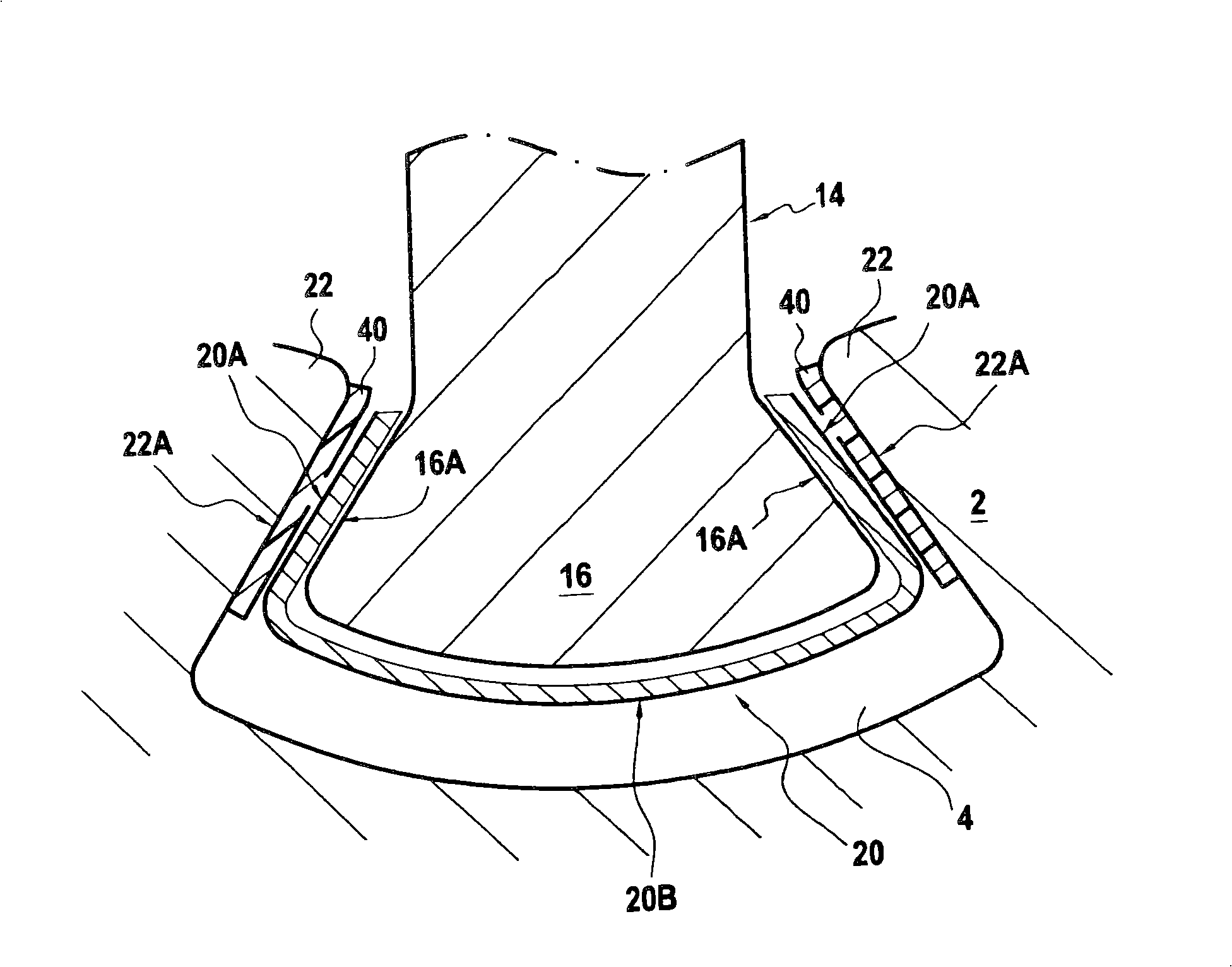

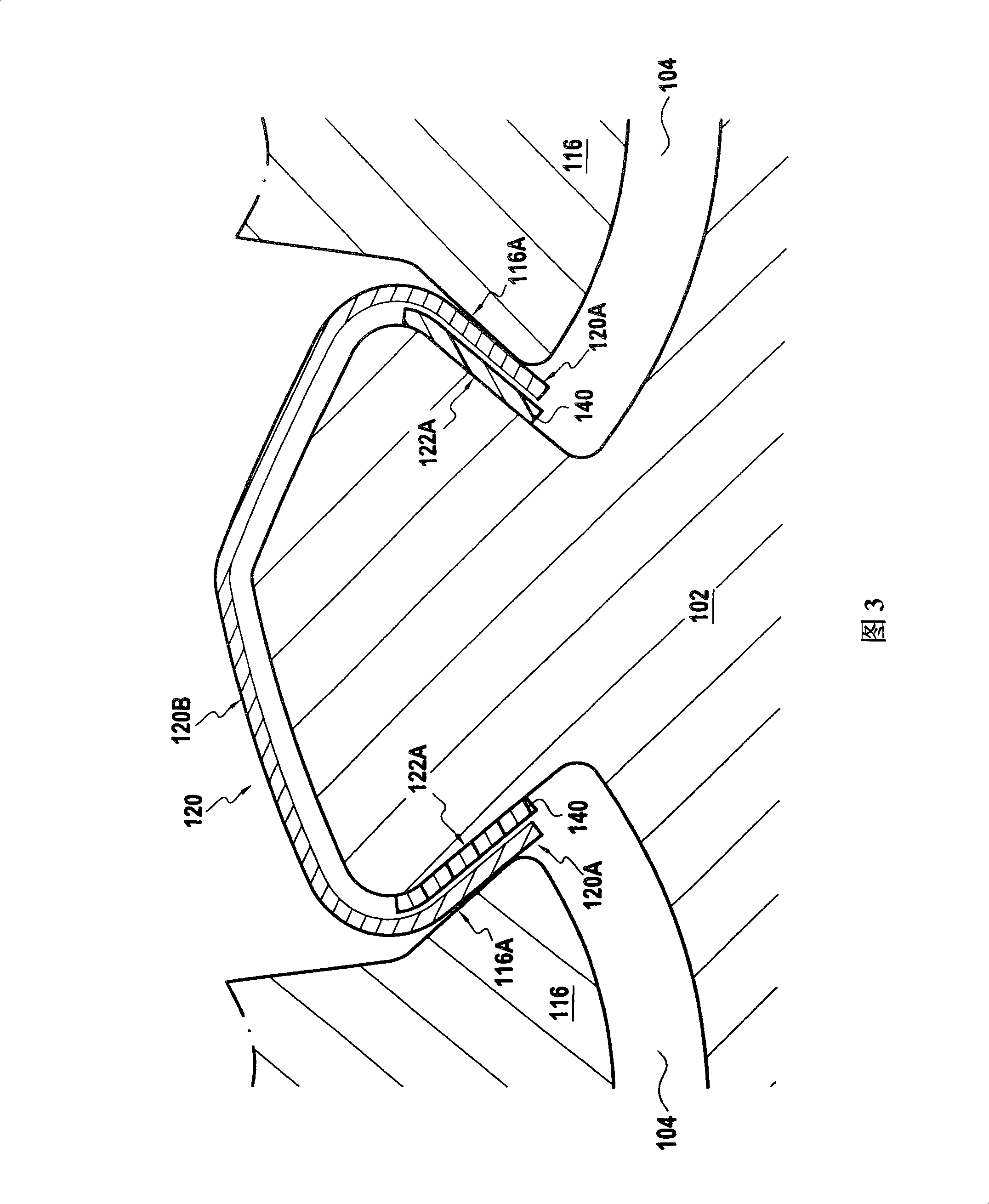

[0026] Such as figure 1 and figure 2 As shown, the rotor disk 2 is provided with a number of grooves or "slots" 4 along its outer edge, which form cavities, each of which can receive a blade root 16 of a blade 14, around which the blade root 16 is lined. Pad 20. The blade root 16 and the fan disk 2 are made of, for example, a titanium alloy.

[0027] It should be noted that these assemblies are also provided with a spacer (not shown) between the blade root 16 and the bottom of the slot 4 .

[0028] When the wheel disk 2 rotates, the blade 14 bears the centrifugal force, and the support surface 16A on the blade root 16 will be tightly pressed on the support surface 22A of the wheel disk 2 . In the example described, the support surfaces 16A form the wings of the blade root 16 , while the support surfaces 22A form the underside of the wheel lip 22 extending on both sides of the outer opening of each slot 4 .

[0029] The liner 20 includes two side walls 20A intended to come...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com