Waste gas bypass valve assembly for supercharger and vehicle

A wastegate valve and supercharger technology, applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of product price increase, complex production process requirements, etc., to reduce the frequency of action and reduce the dimensional accuracy requirements , The effect of improving durability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

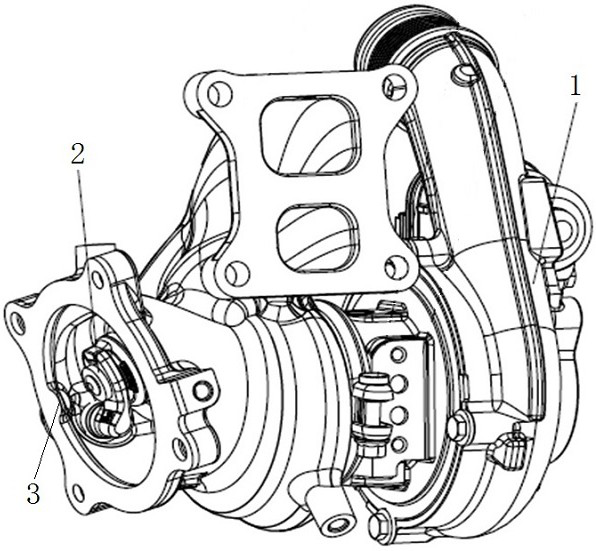

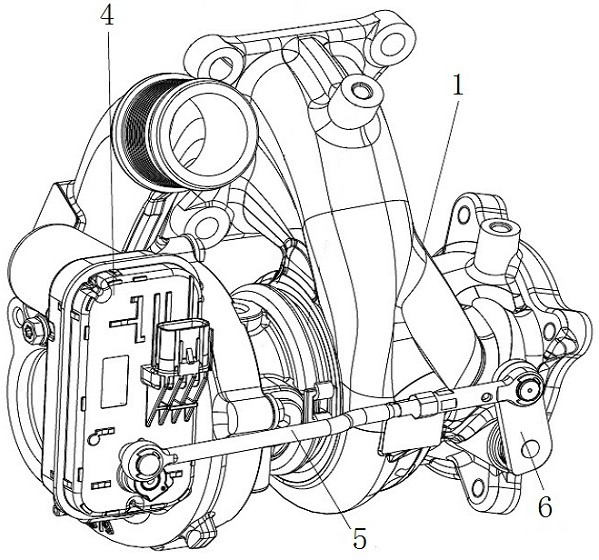

[0032] see figure 1 with Figure 10 , the wastegate valve assembly for the supercharger shown includes a volute 1 and a wastegate assembly 2, the wastegate assembly 2 is arranged in the wastegate hole 11 inside the volute 1 On the open side and can be flipped open to one side, the inner side wall of the volute 1 close to the wastegate valve assembly 2 is provided with a limit protrusion 3, when the wastegate valve assembly 2 is opened to the maximum angle, the limit The protrusion 3 interferes with the wastegate assembly 2 .

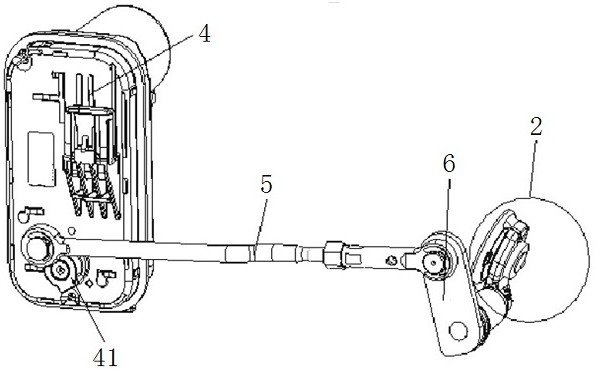

[0033] see Figure 4 with Figure 5 , the wastegate assembly 2 includes a valve plate 21, a gasket 22 and a rocker arm 23, one end of the rocker arm 23 is connected to the actuator 4, and the other end is provided with a connecting plate 24, and the connecting plate 24 is provided with A through hole 241 that is loosely fitted with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com