Method for controlling quality of molded shoes with cloth cover

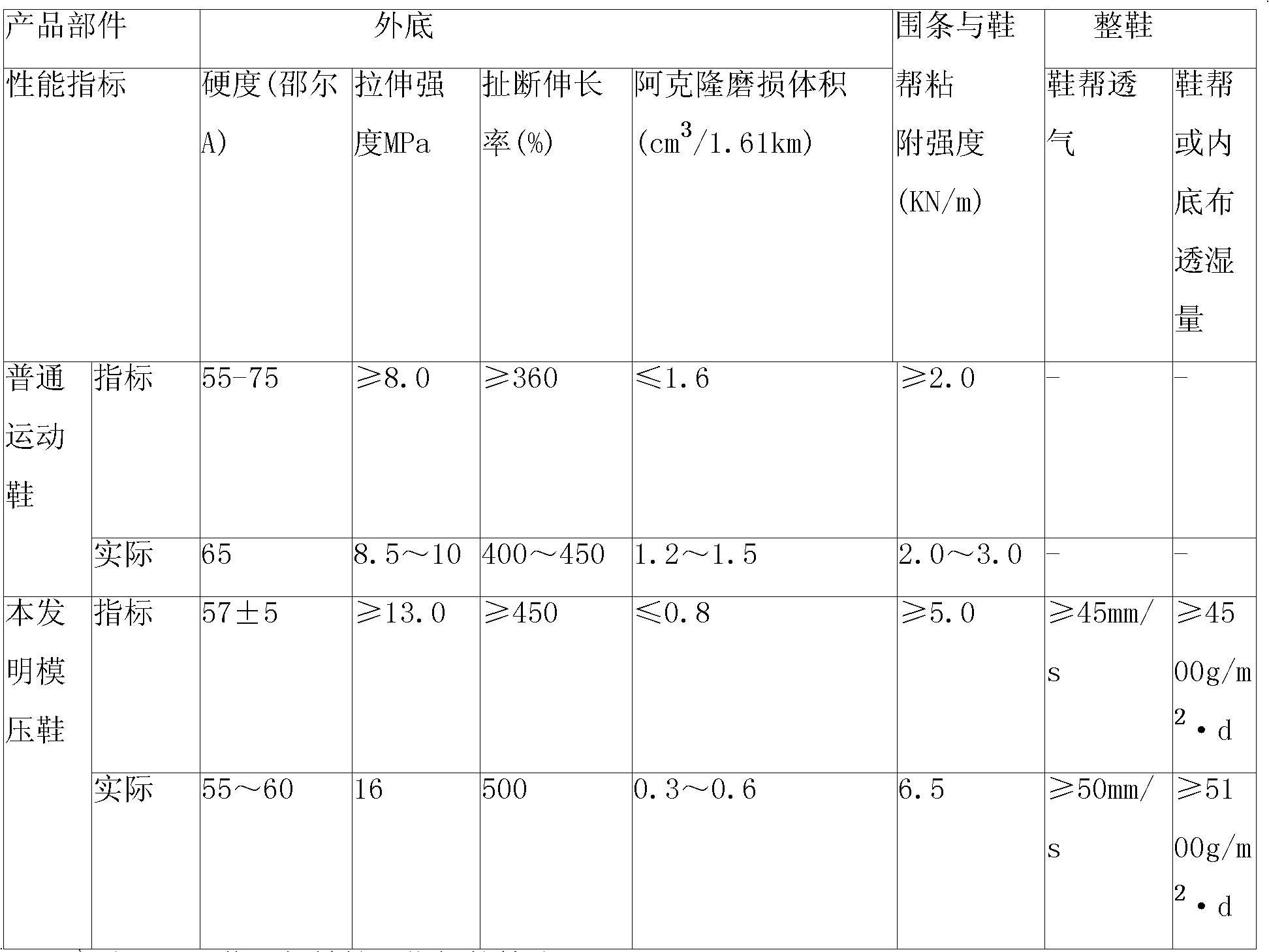

A quality control method and molding technology, applied to footwear, adhesive shoe parts, shoe-making machinery, etc., can solve the problems of low product value, no quality control method for cloth-covered molded shoes, molded shoes that do not meet the wearing life, etc. , to achieve the effect of improving quality and ensuring wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

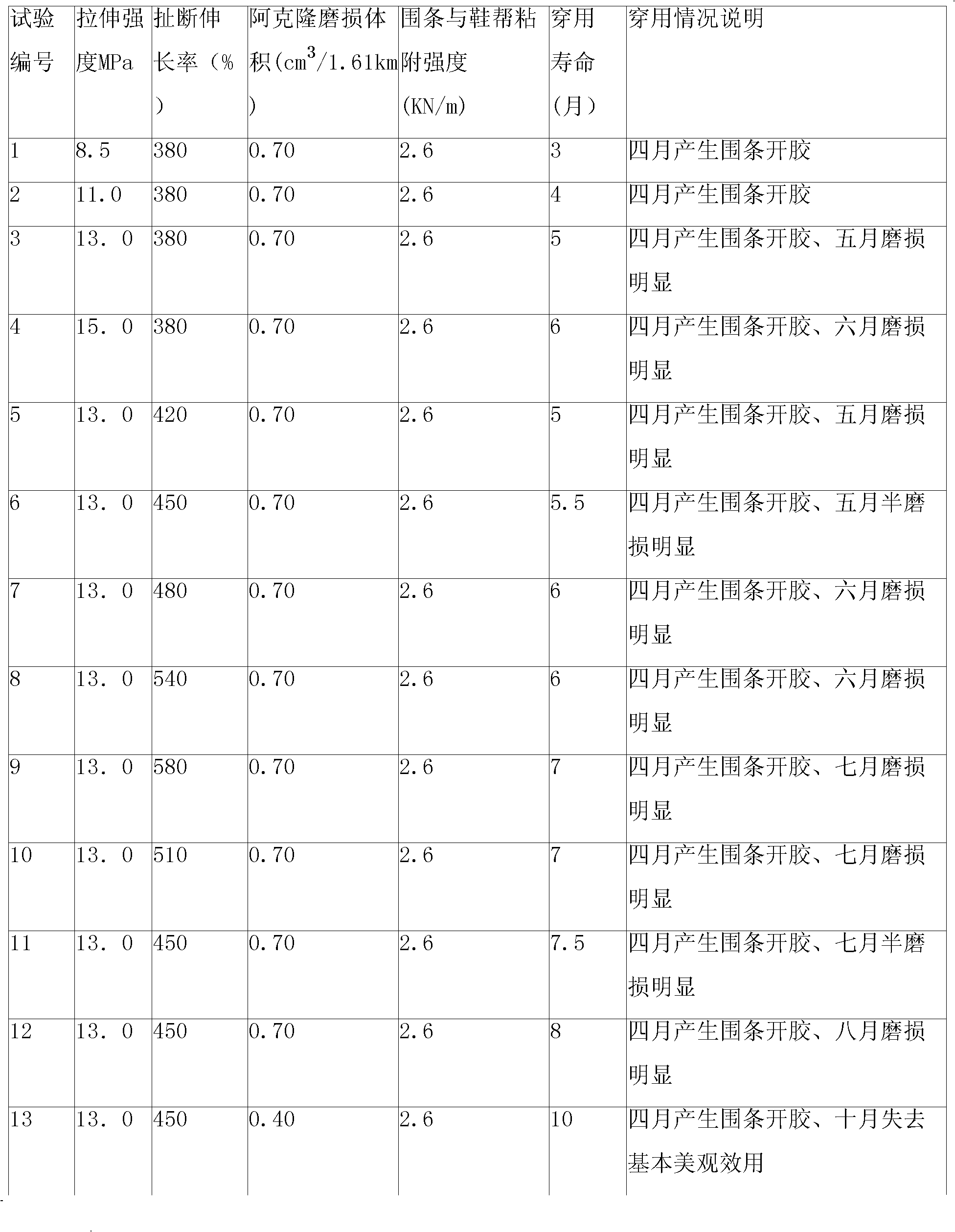

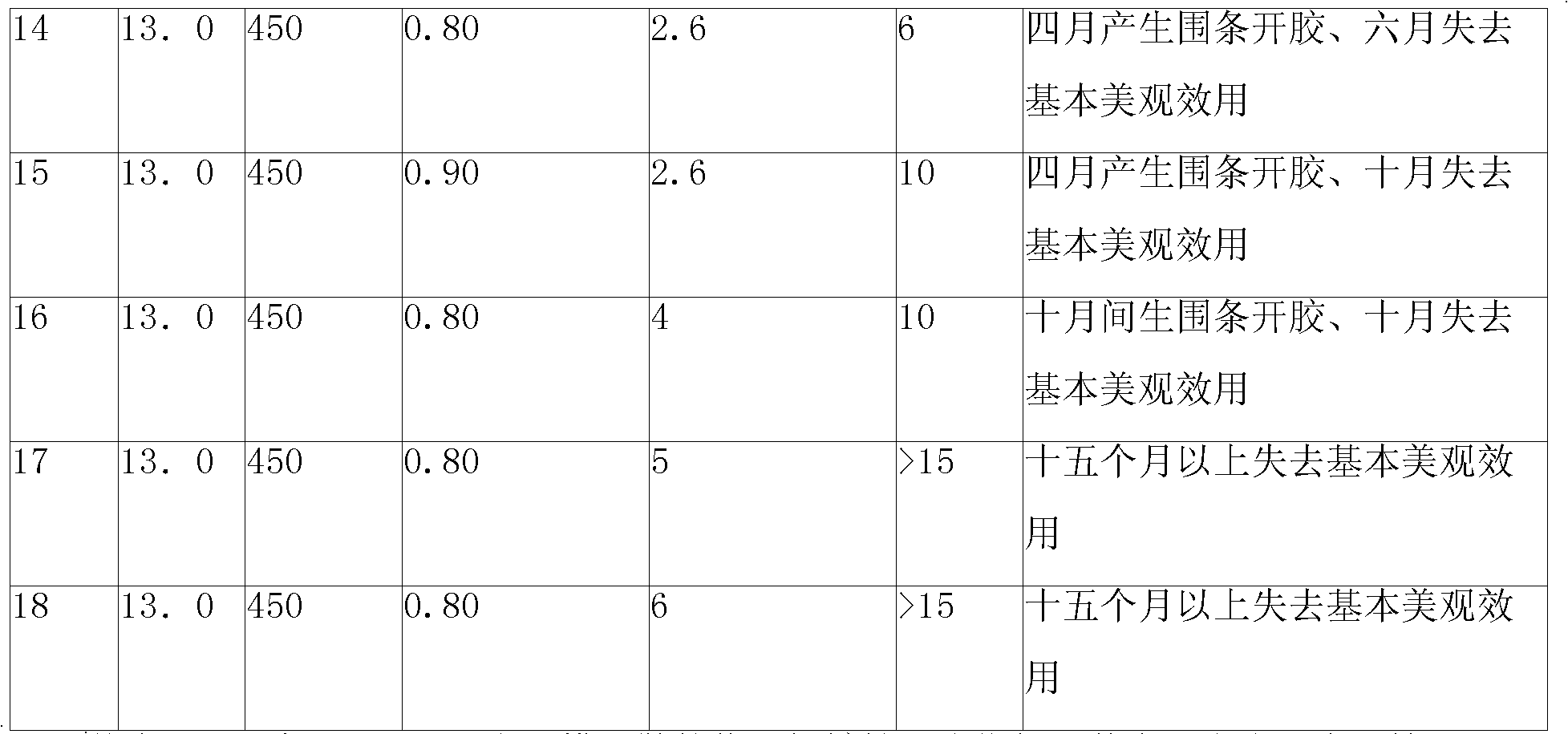

Examples

Embodiment approach

[0062] The inspected products are taken as a batch, and three pairs are selected from them for inspection.

[0063] The first is the performance control of the main and auxiliary raw materials:

[0064] (1) Standard natural rubber: the breaking strength of raw rubber is not less than 19.6MPa, and the elongation at break is not less than 680%;

[0065] (2) High wear-resistant carbon black: a) Pure carbon black test indicators: PH value 7-9.5, oil absorption value 0.90-1.15, DPG adsorption rate 4-8%, 100-mesh sieve residue less than 0.02%; b) physical Performance index (Physical properties of the film prepared according to the following ratio: 300g smoked rubber, 9g stearic acid, 3g anti-aging agent CD, 15g zinc oxide, 1.8g accelerator M, 9g pine tar, 9g sulfur, high wear resistance Carbon black 150g, total 496.8g.): tear strength ≥ 24.5MPa, elongation at break ≥ 470%, 300% elongation strength ≥ 11.76MPa, Acron wear volume ≤ 0.22cm 3 / 1.61km;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com