Inner sticky pad type film sealed vacuum hemostix

A vacuum blood collection tube and membrane sealing technology, which is applied to sensors, diagnostics, packaging items, etc., can solve the problems of easy hand injury, many edges and corners, air pollution, etc., and achieves easy disinfection and cleaning, stable components, and avoids pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

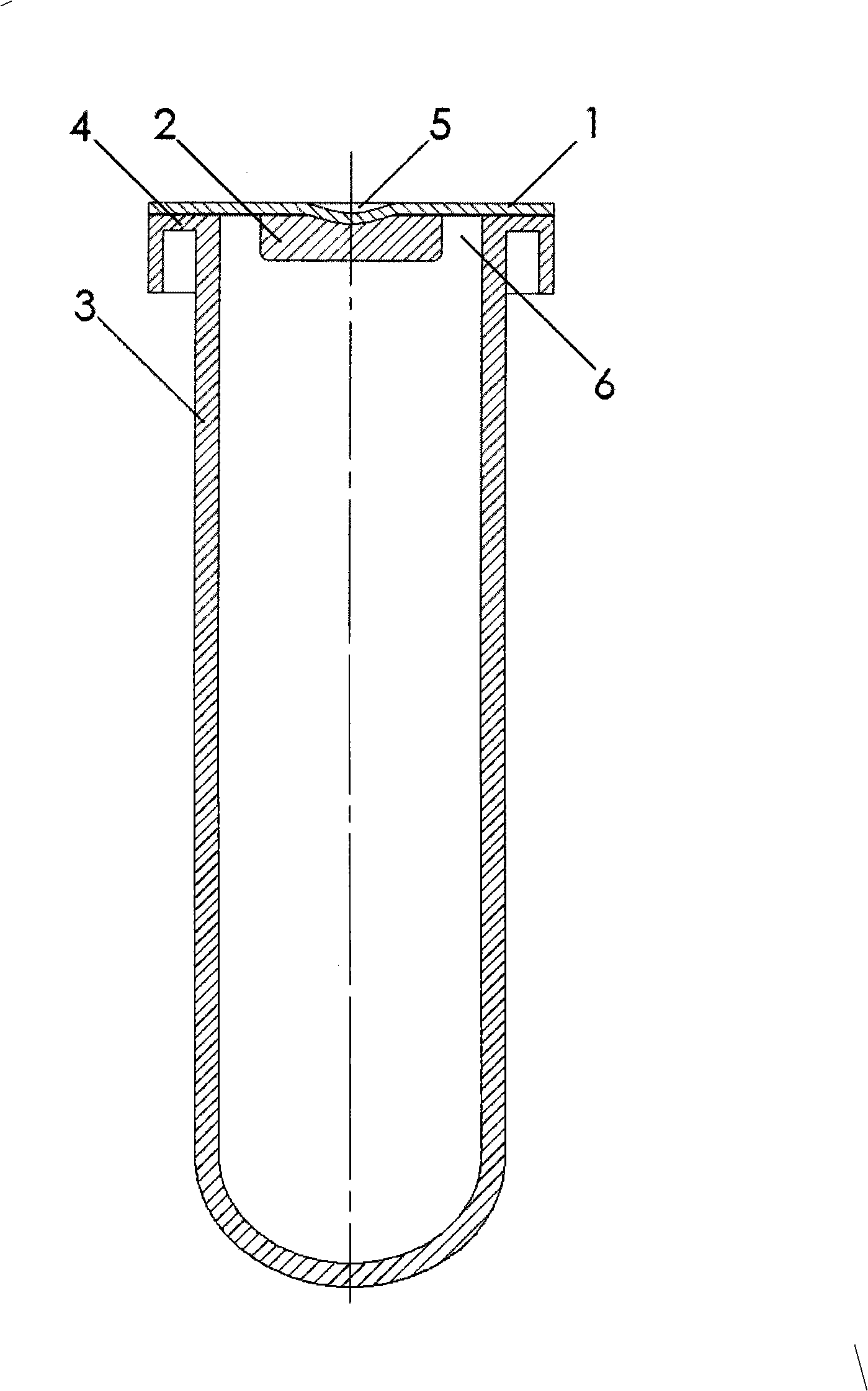

[0009] As shown in the accompanying drawings, it is the inner adhesive pad type membrane-sealed vacuum blood collection tube proposed by the present invention, including a vacuum test tube 3, a sealing film 1 and an elastic pad 2, and the elastic pad 2 is bonded to the lower surface of the sealing film 1 The central position is located in the cavity formed after the sealing film 1 and the vacuum test tube 3 are sealed. There is a gap 6 between the outer peripheral edge of the elastic pad 2 and the inner wall of the mouth of the vacuum test tube 3. The outer peripheral edge of the lower surface of the sealing film 1 and the The vacuum test tube mouth 4 is sealed; the elastic pad 2 is directly coated and molded on the lower surface of the pre-made sealing film 1, and is adhered to the lower surface of the sealing film 1 by the initial viscosity of the elastic pad forming and placed naturally Finally, the final curing of the elastic pad 2 is completed, and the thickness of the ela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com