Braking device of drive axle

A technology of braking device and drive axle, applied in manual starting device, power device, control device, etc., can solve the problems of unstable braking, high cost, complex braking system, etc., and achieve stable braking and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

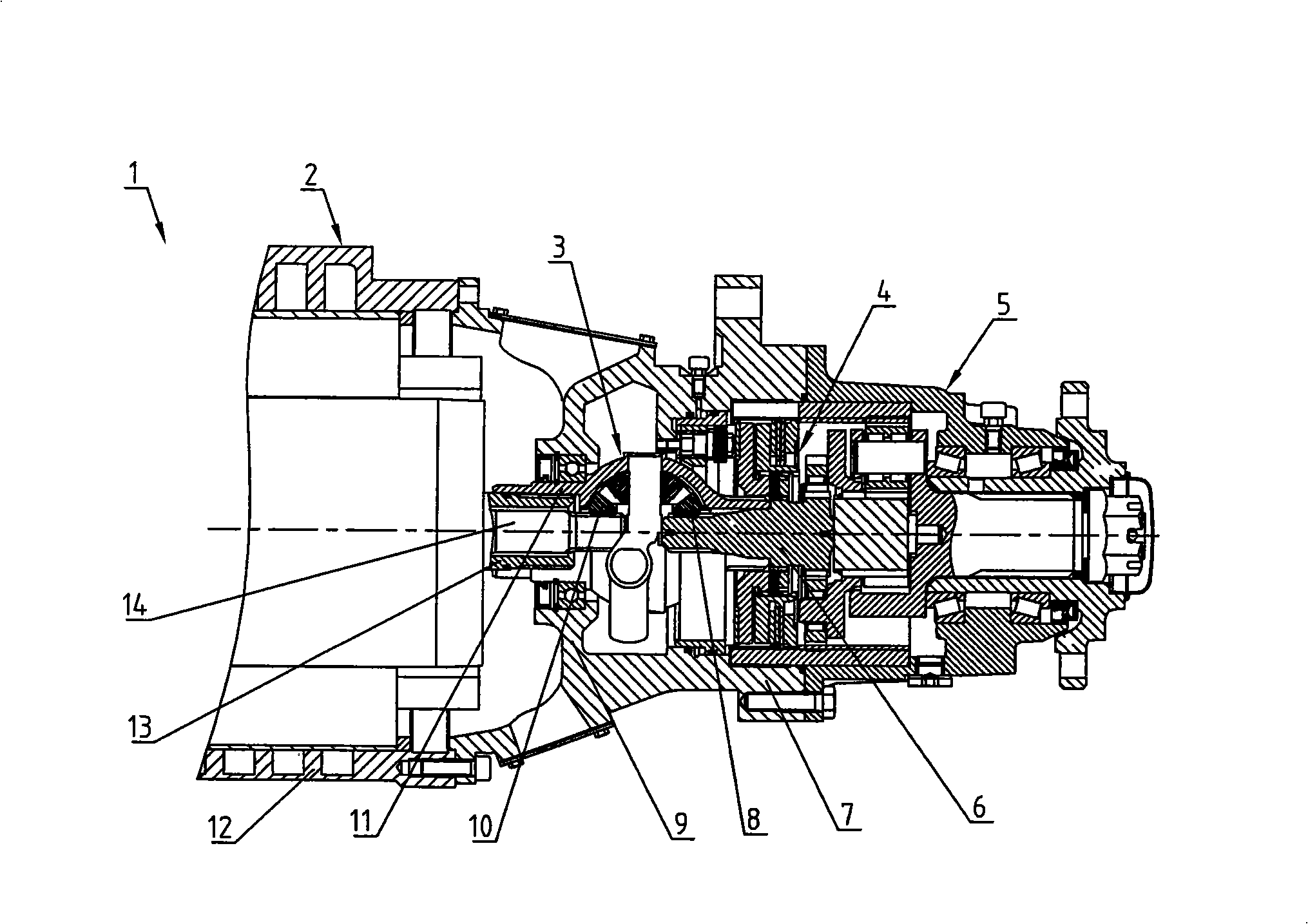

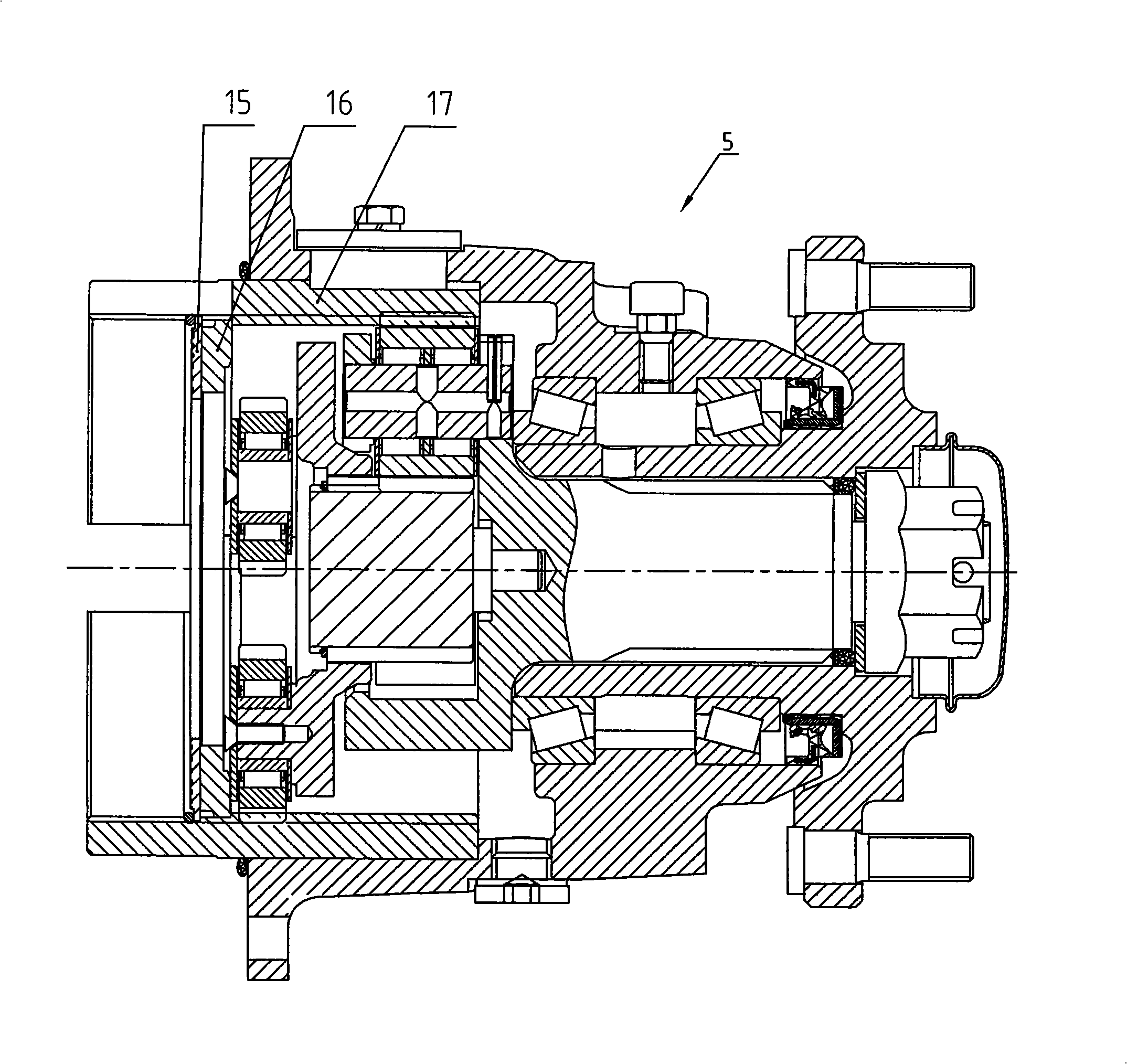

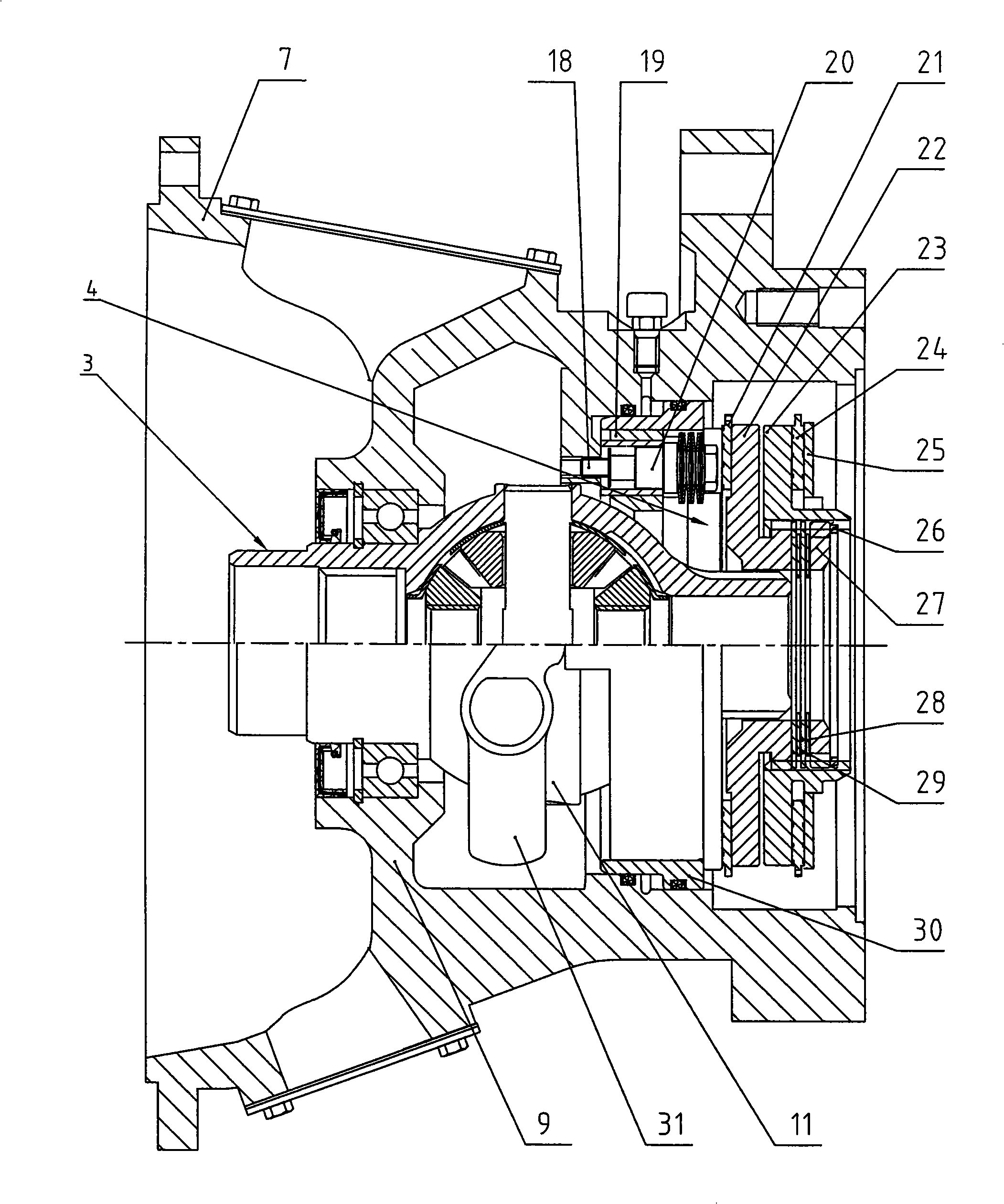

[0025] figure 1 ~As shown in Figure 9, it includes drive axle 1, motor 2, differential 3, braking device 4, planetary gear reducer 5, sun gear shaft 6, motor end cover 7, side gear 8, separator 9, half shaft Gear 10, differential case 11, motor housing 12, motor shaft 13, transmission shaft 14, first main friction plate 15, fixed disc 16, inner ring gear 17, limit bolt 18, first pressure plate 19, Limiting sleeve 20, large friction plate 21, second pressure plate 22, third pressure plate 23, second main friction plate 24, main friction plate 25, retaining ring 26, brake ring gear 27, auxiliary friction plate 28, auxiliary Friction disc 29, piston 30, shift fork 31, handle 32, shift fork end cover 33, adjustment bolt 34, adjustment nut 35, protrusion 36, boss 37, flange 38, cylinder 39, groove 40, through Hole 41.

[0026] like figure 1 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com