Phosgene recovery method for toluene diisocyanate production process

A technology of toluene diisocyanate and recovery method, which is applied in carbonyl chloride, organic chemistry, etc., can solve the problems of toluene refining towers such as high hazards, increased lye consumption, and high HCl flow rate, so as to reduce corrosion damage, reduce mass fraction, and reduce The effect of the discharge of spent lye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

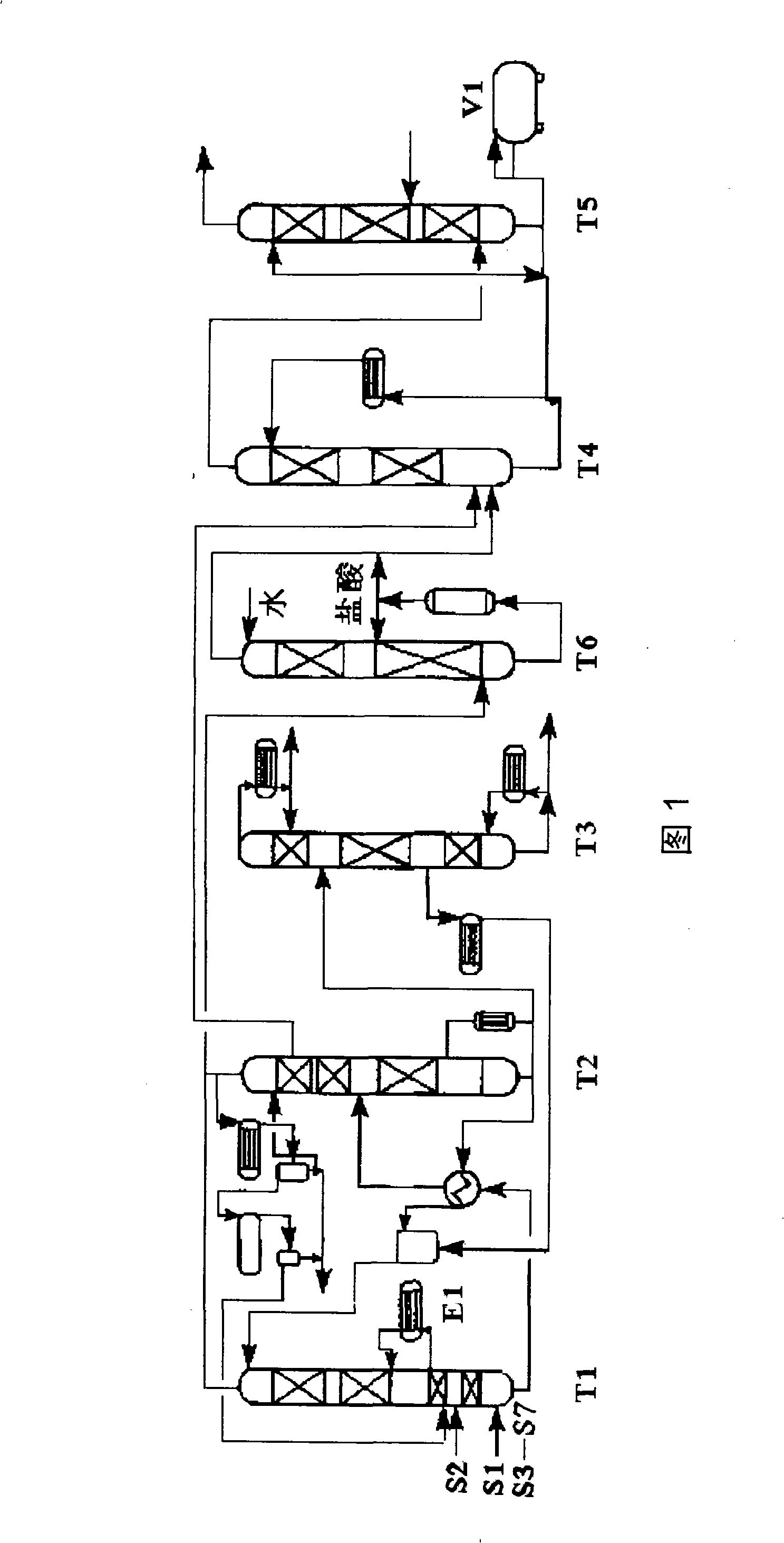

[0012] The present invention relates to a method for recovering phosgene in the production process of toluene diisocyanate. The material containing HCl, ethyl chloride and phosgene is first absorbed by toluene, then the toluene absorption system is cooled, and the HCl non-condensable gas is absorbed by lye, and then The toluene absorption liquid that has absorbed ethyl chloride and phosgene is separated, and the separated toluene is recycled, and the phosgene destruction process is carried out on the separated phosgene material containing ethyl chloride, and the removed ethyl chloride is Neutralize with lye, and recycle the separated phosgene to the phosgene chamber.

[0013] As shown in Figure 1, the material containing HCl, ethyl chloride and phosgene enters the toluene absorption tower T1, and the phosgene is absorbed by toluene. The feed to the toluene absorption tower T1 is divided into two parts, one part enters from the bottom of the tower, and the other part enters from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com