Boiler molded coal and preparation thereof

A boiler and weight technology, which is applied in the field of environmentally friendly boiler briquette and its preparation, can solve the problems of difficulty in making boiler briquette with suitable strength, low cooling and heating strength, and low sulfur content, and achieves increased specific surface and oxygen. The effect of diffusion capacity, small exhaust heat loss and low ignition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

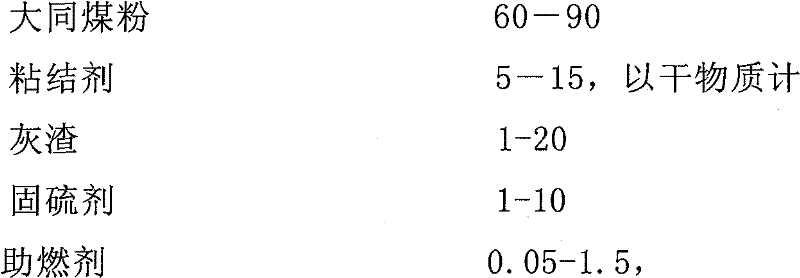

Method used

Image

Examples

Embodiment 1

[0045] The preparation of embodiment 1 binding agent

[0046] First, 50 parts of tap water are metered into the reaction kettle, and then 0.5 parts of the 40% caustic soda solution in the storage tank are pumped into the high-level metering tank with a pump, and metered into the reaction kettle with a steam heating jacket, and the reaction kettle is started to stir. After stirring for 5 minutes to make the mixture uniform, 8 parts of solid starch substances (starch factory leftovers) were added to the reactor by an electric hoist, and steam was introduced into the jacket of the reactor and heated to a temperature of 75° C. for 30 minutes to obtain Adhesive, which is pumped into the storage tank for use.

Embodiment 2

[0047] The preparation of embodiment 2 binding agent

[0048] First, 90 parts of tap water are metered into the reaction kettle, and then 3 parts of 40% caustic soda solution in the storage tank are pumped into the high-level metering tank with a pump, and metered into the reaction kettle with a steam heating jacket, and the reaction kettle is started to stir After stirring for 5 minutes to make the mixture uniform, 30 parts of solid starch (starch factory leftovers) were added to the reactor by an electric hoist, and steam was introduced into the jacket of the reactor and heated to a temperature of 80°C for 20 minutes. The binder is obtained, which is pumped into a storage tank for use.

Embodiment 3

[0049] The preparation of embodiment 3 binding agent

[0050] First, 70 parts of tap water are metered into the reaction kettle, and then 1.25 parts of 40% caustic soda solution in the storage tank are pumped into the high-level metering tank with a pump, and metered into the reaction kettle with a steam heating jacket, and the reaction kettle is started to stir. After stirring for 5 minutes to make the mixture uniform, 15 parts of solid starch substances (starch factory leftovers) were added to the reactor by an electric hoist, and steam was introduced into the jacket of the reactor and heated to a temperature of 70 ° C for 30 minutes to obtain Adhesive, which is pumped into the storage tank for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com