Collard jujube pieces

A technology of kale and jujube fruit, applied in the direction of confectionary, confectionary industry, food preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

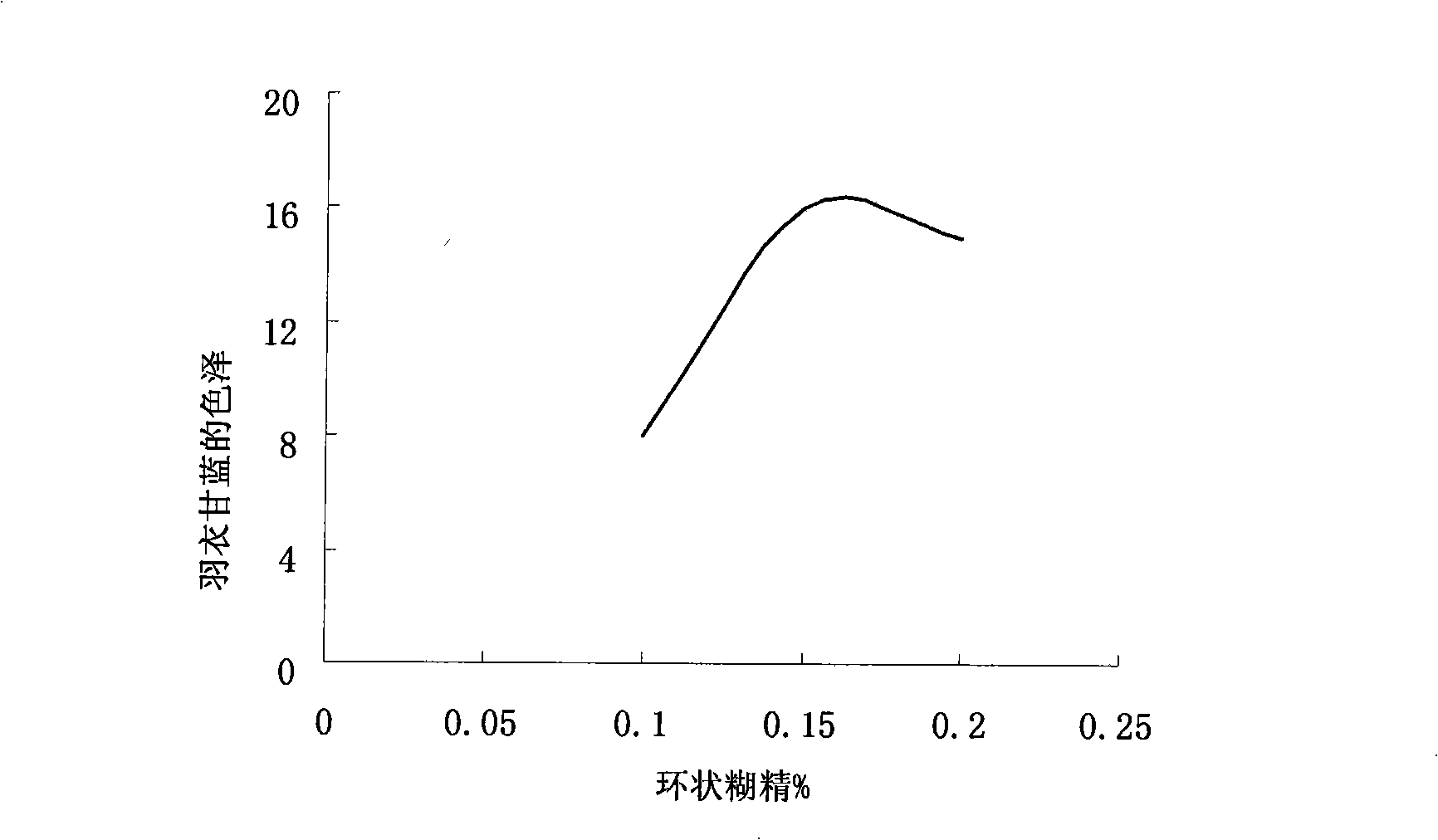

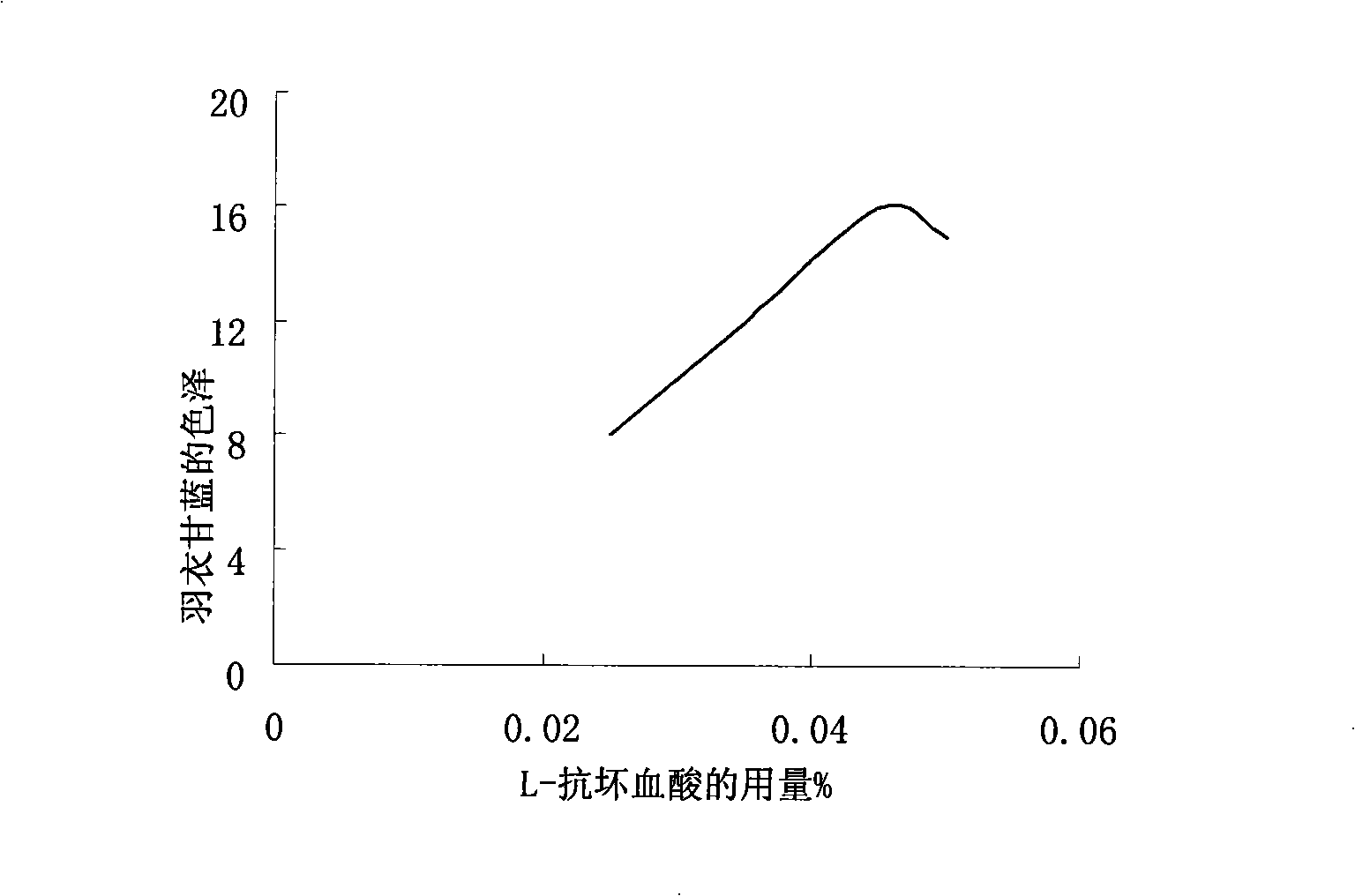

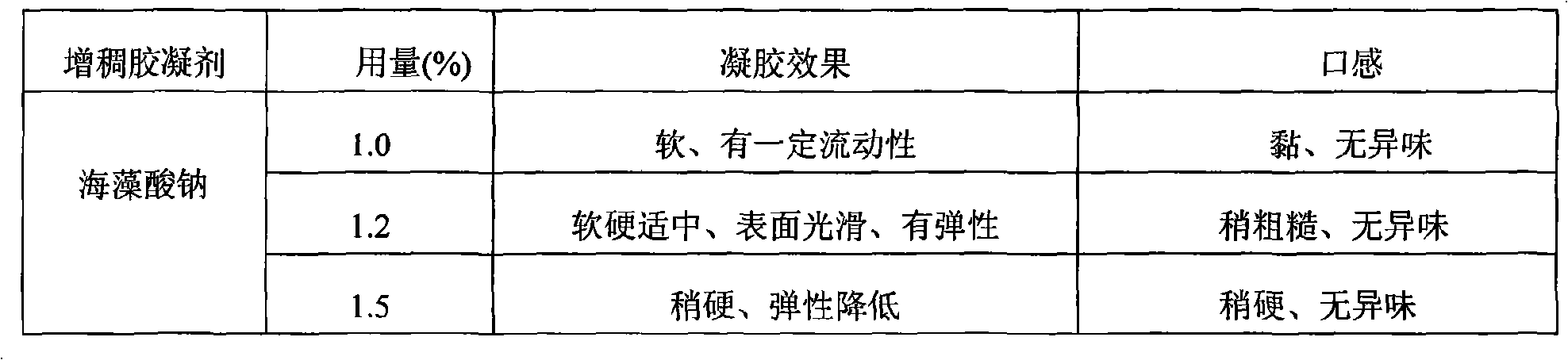

[0048] Embodiment 1, a kind of kale jujube slice is made up of 5 parts of red dates, 2 parts of kale, 1.4% agar of red dates and kale gross weight, 0.15% beta-cyclodextrin, 0.035% L-ascorbic acid,

[0049] The processing method is that the dried kale is soaked in 20-degree water for 12 hours until the water content reaches about 70%, then steamed, and then beaten until it becomes a paste. Refined. Red dates are pitted, beaten, passed through a 100-mesh sieve, and the skin of the dates is removed. Stir the paste-like kale, skinless date paste, and melted agar in a blending tank according to the proportion until uniform, and heat to above 85°C, keep it for 15 minutes, and cool to shape.

Embodiment 2

[0050] Embodiment 2, a kind of kale jujube slice is made up of 4 parts of red dates, 1 part of kale, 1.2% agar, 0.20% beta-cyclodextrin, and 0.045% L-ascorbic acid of the total weight of red dates and kale,

[0051] The processing method is as follows: dry kale, soak it in 20°C water for 12 hours until the water content reaches about 70%, then steam it, and beat it until it becomes a paste. In order to prevent the kale from browning, add L-ascorbic acid, β-cyclo dextrin. Red dates are pitted, beaten, passed through a 100-mesh sieve, and the skin of the dates is removed. Stir the paste-like kale, skinless date paste, and melted agar in a blending tank according to the proportion until uniform, and heat to above 85°C, keep it for 15 minutes, and cool to shape.

Embodiment 3

[0052] Embodiment 3, a kind of kale jujube slice is made up of 6 parts of red dates, 3 parts of kale, 1.5% agar, 0.18% beta-cyclodextrin, and 0.040% L-ascorbic acid of the total weight of red dates and kale,

[0053] The processing method is that the dried kale is soaked in 20-degree water for 12 hours until the water content reaches about 70%, then steamed, and then beaten until it becomes a paste. Refined. Red dates are pitted, beaten, passed through a 100-mesh sieve, and the skin of the dates is removed. Stir the paste-like kale, skinless date paste, and melted agar in a blending tank according to the proportion until uniform, and heat to above 85°C, keep it for 15 minutes, and cool to shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com