Ceramic high barrier film apparatus of continuous winding type magnetron sputtering manufacture

A magnetron sputtering and winding device technology, which is applied in sputtering coating, ion implantation coating, metal material coating process, etc., can solve the problems of non-continuous production, re-vacuumization, low production capacity, etc., and achieve Increased efficiency, increased vacuuming speed, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

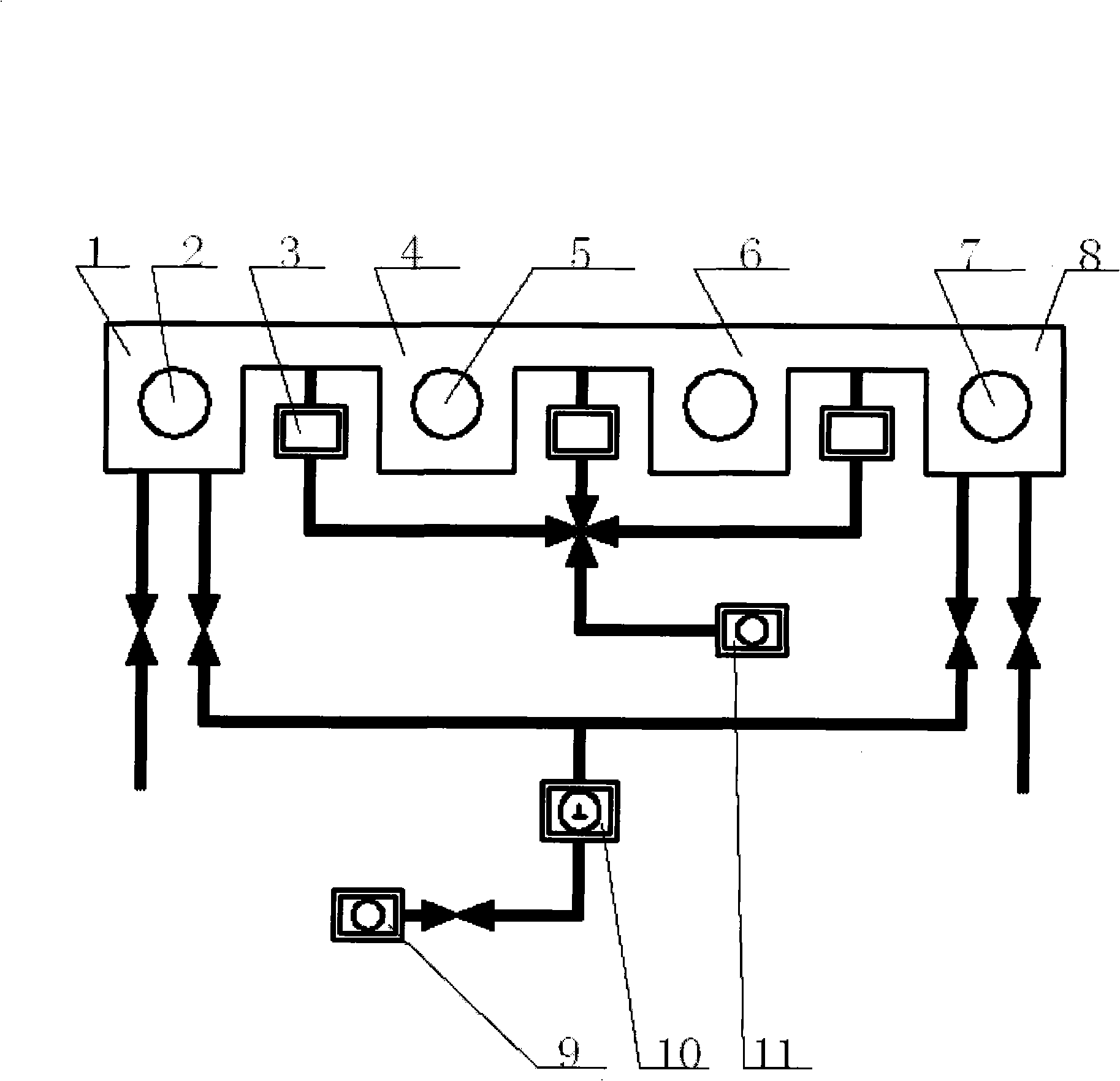

[0018] combine figure 1 , this example includes:

[0019] 1. The unwinding vacuum chamber 1 and the winding vacuum chamber 8, at least one coating vacuum chamber, the vacuum connection box connecting the winding, unwinding vacuum chamber and the coating vacuum chamber, and the coating vacuum chamber has a cooling roller located in the vacuum coating box A vacuum pumping system consisting of at least three sets of cathodes, high and low pressure vacuum pumps and pipelines is arranged around the cooling roller. The cathode target and target core of the magnetron sputtering are set in each vacuum coating box, and the cathode passes through the cathode. The flange connection seat is installed on the wall of the vacuum coating box in the form of flange connection, and the connecting pipelines of gas, power supply and cooling water are placed outside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com