Method for removing photoresist

A photoresist and cleaning solution technology, applied in photosensitive material processing, electrical components, semiconductor/solid-state device manufacturing, etc. Reduce the effect of dilution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

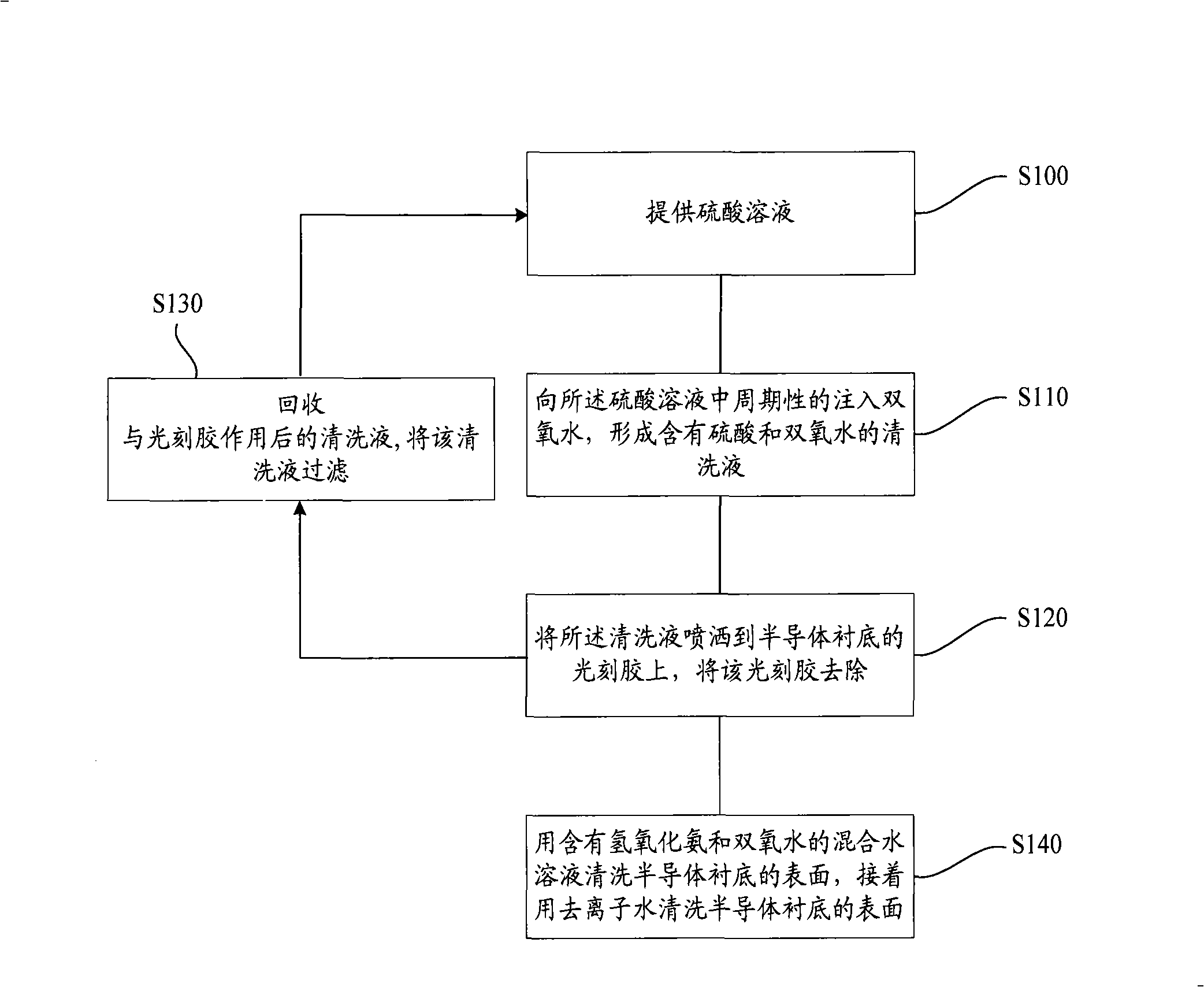

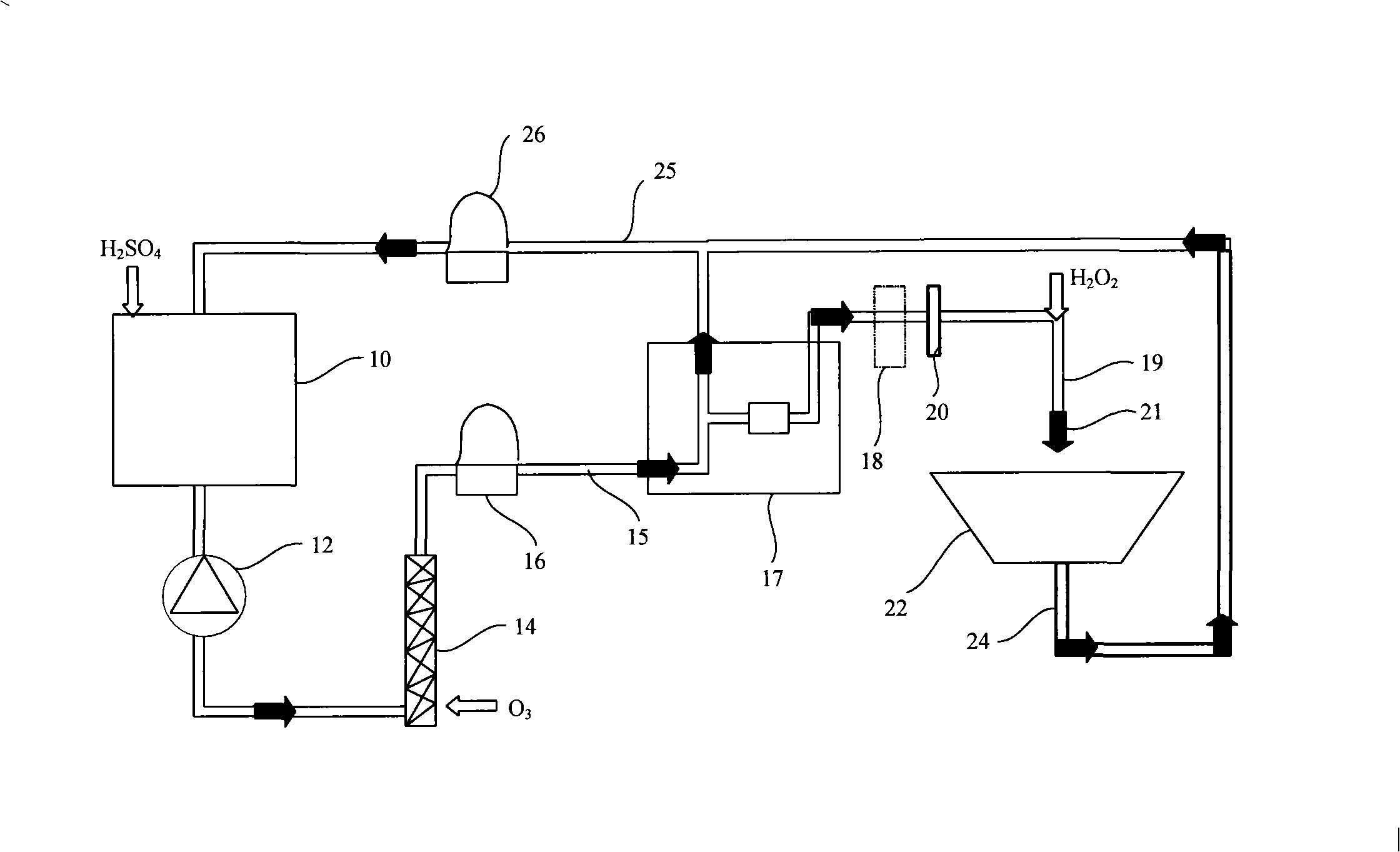

[0037] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] In the semiconductor integrated circuit process, the photoresist is spin-coated on the surface of the semiconductor substrate through the photolithography process to define the area to be etched or ion implanted; after the etching or ion implantation is completed, the photoresist on the surface of the semiconductor substrate needs be removed. The invention provides a method for removing a photoresist layer.

[0039] In the method for removing photoresist of the present invention, at first, provide sulfuric acid solution, this sulfuric acid solution is used as the cleaning solution of removing photoresist;

[0040] Next, periodically inject hydrogen peroxide into the sulfuric acid solution to form a cleaning solution containing sulfuric acid and hydrogen peroxide;

[0041] Periodically inject hydrogen peroxide into the cleaning sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com