Method for manufacturing hook type commutator

A manufacturing method and commutator technology, applied in the direction of commutator manufacturing, etc., can solve the problems of many machining steps, large material waste, long production cycle, etc., achieve smooth cutting surface, avoid hook foot deflection, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

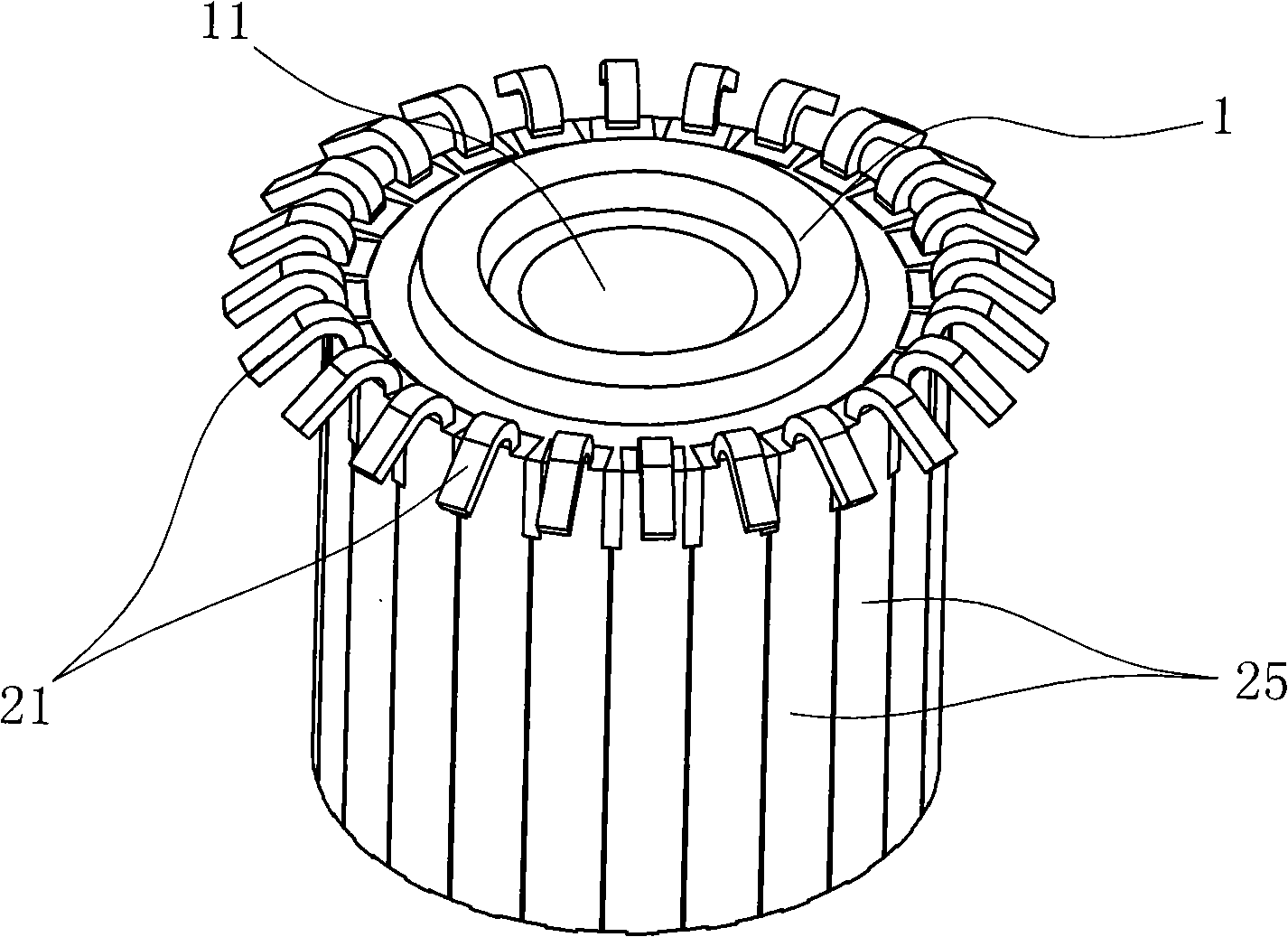

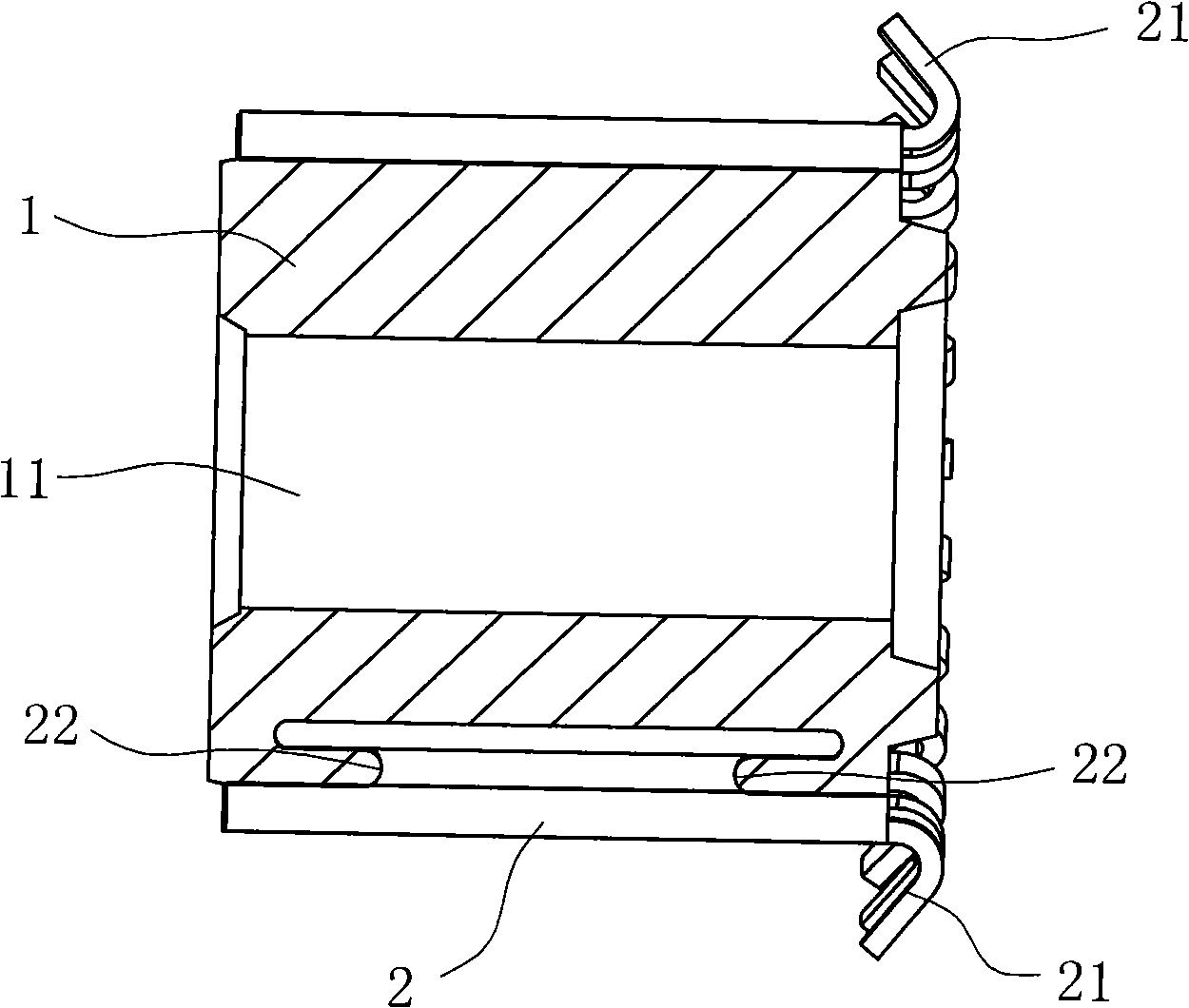

[0037] Examples, see figure 2 ~5:

[0038] Such as figure 2 , image 3 As shown, the commutator is a hook type commutator, including a commutator base 1, the commutator base 1 is made by injection molding of engineering plastics injection mold 4, and the commutator base 1 is inserted with A plurality of commutation segments 2, each commutation segment has a bent hook foot 21.

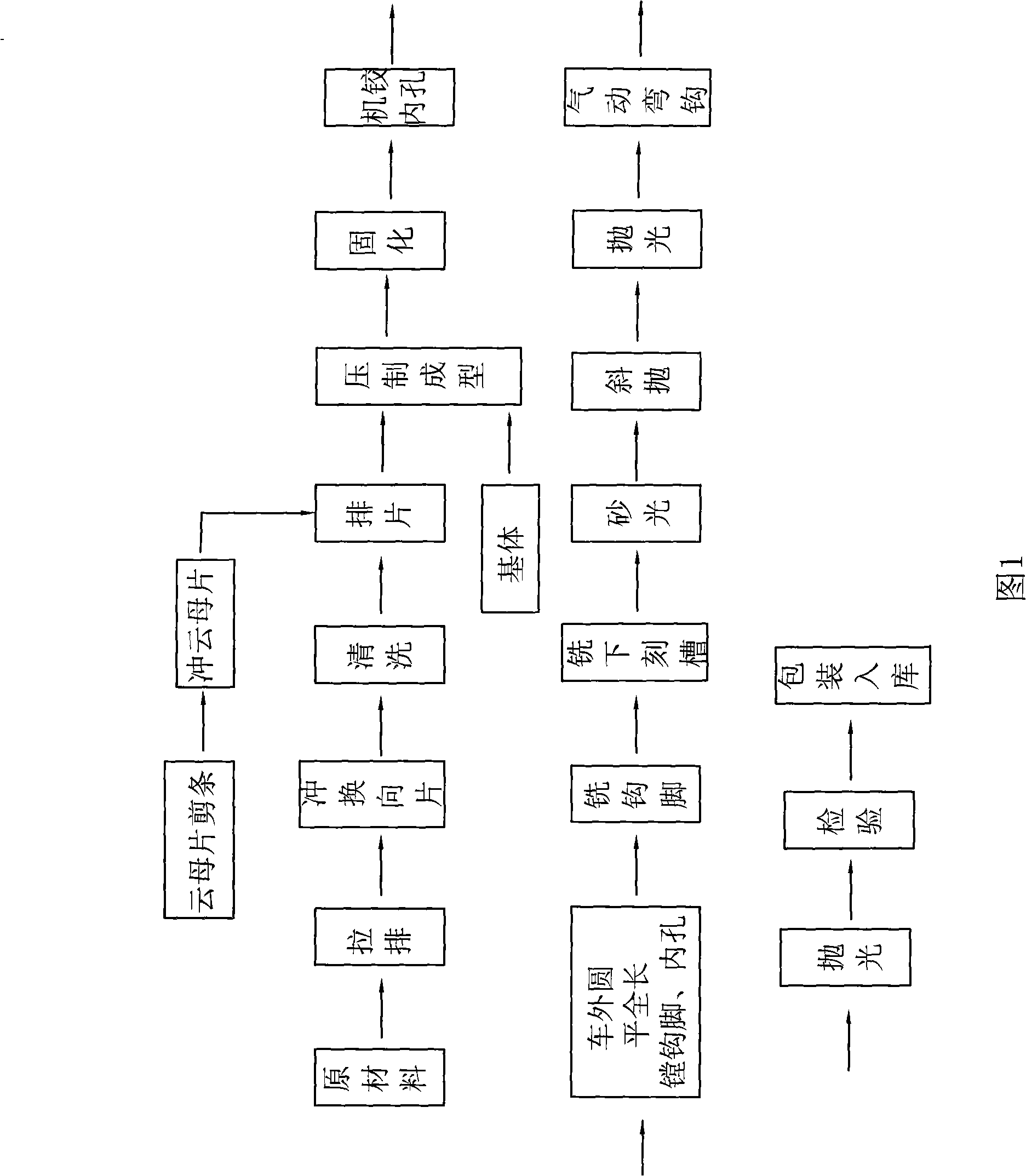

[0039] The production of the commutator segment 2 of the present invention adopts the hierarchical punching method, that is, no turning allowance is left in the direction of the outer circle 25 of the commutator segment 2, that is, after the commutator segment 2 is inserted into the commutator base 1, the overall outer diameter Turning is not required, and the subsequent commutator segment size machining process is omitted. The manufacturing method of this commutator, referring to Fig. 10, comprises the following steps:

[0040] ①. Using copper as raw material, cutting and drawing into copper bar 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com