Method for pressed forming multilayer electrical brush

A technology of pressing and forming brushes, which is applied in the field of pressing and forming multi-layer brushes, can solve the problems of no further disclosure and the inability to realize the continuous addition of different types of materials, and achieve the effect of multiple feeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

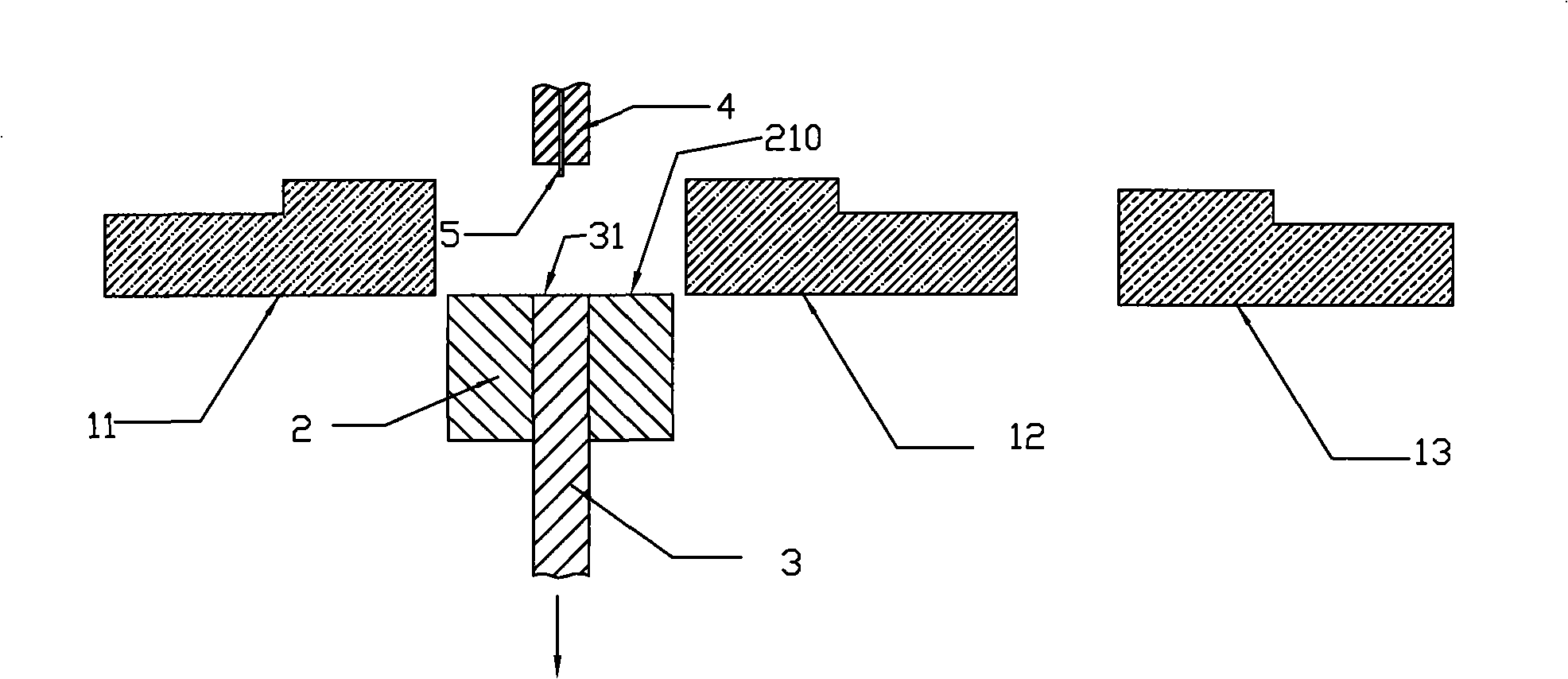

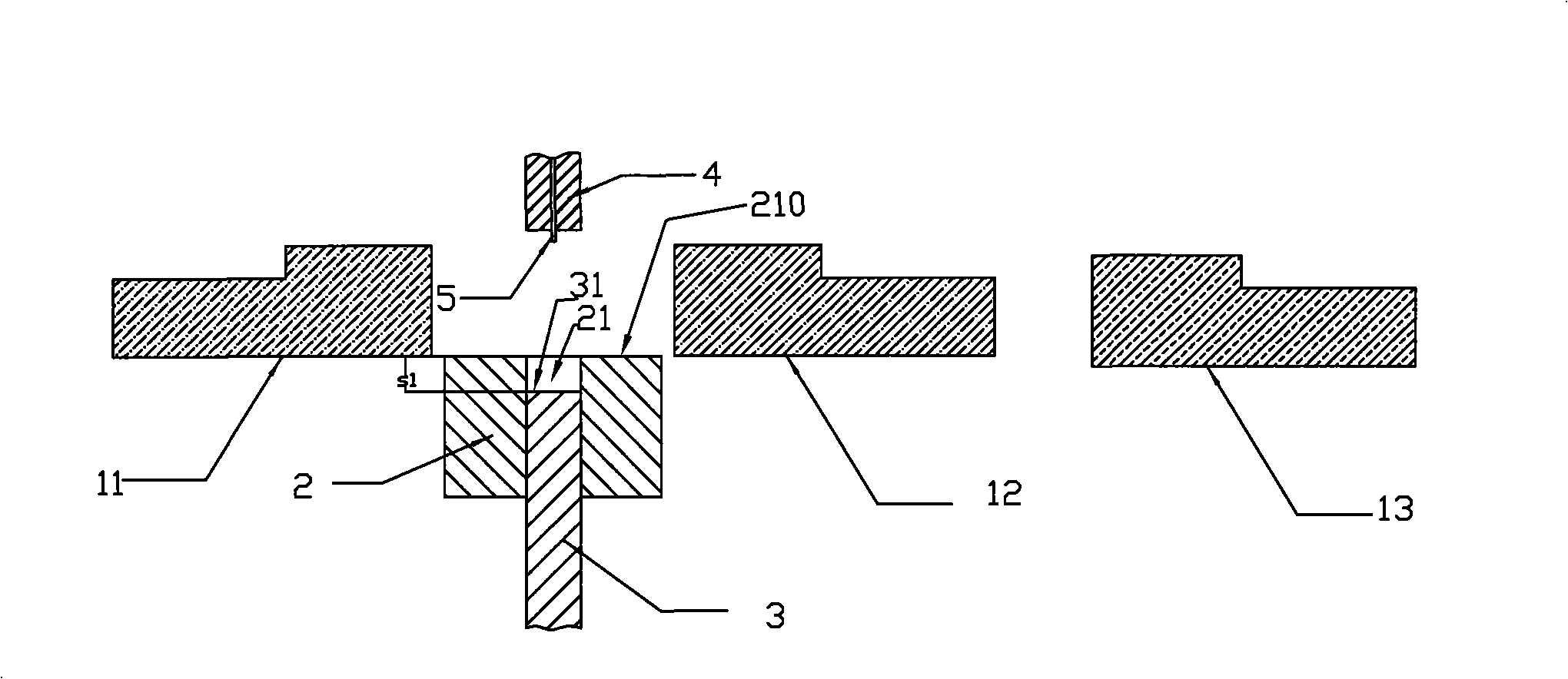

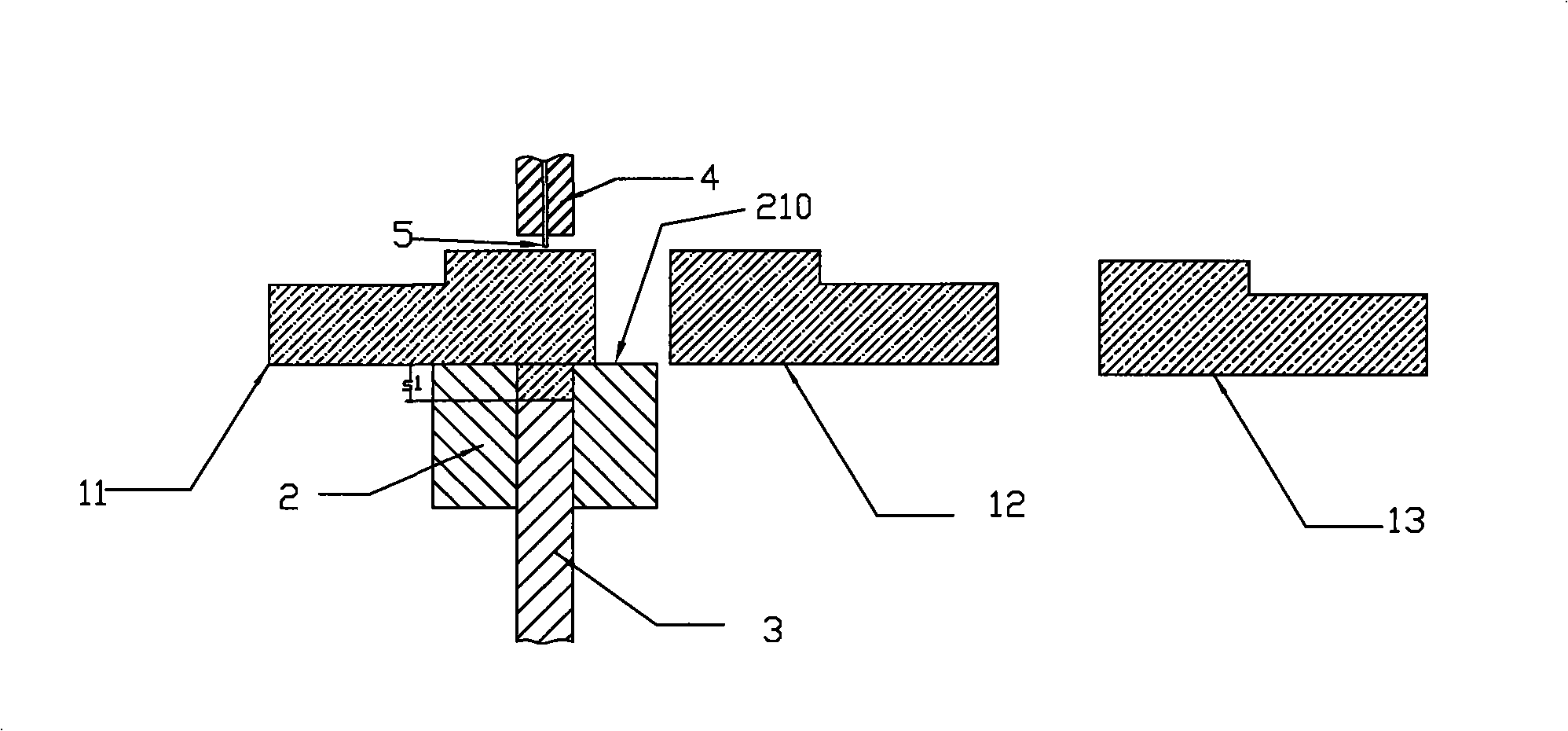

[0033] Such as Figure 1-Figure 8 As shown, this embodiment takes the manufacture of a three-layer brush as an example to illustrate the press-forming method of the multi-layer brush of the present invention. Such as figure 1 As shown, the first pusher 11, the second pusher 12, the third pusher 13, the die 2, the lower punch 3 located in the cavity 21 of the die 2 and the die located in the die 2. The upper punch 4 with a wire hole above and the wire 5 passing through the wire hole are all in the initial state, wherein the upper end surface 31 of the lower punch 3 is on the same plane as the cavity entrance of the die 2. 210 are on the same plane. Such as figure 2 As shown, the distance s1 that the upper end surface 31 of the lower punch 3 needs to move downward relative to the plane 210 where the cavity entrance is located is calculated according to the mass of the first raw material that needs to be filled, that is, the distance s1 for filling the first raw material The...

Embodiment 2

[0036] Such as Figure 9-Figure 12 As shown, this embodiment takes the manufacture of a two-layer brush as an example to illustrate the press-forming method of the multi-layer brush of the present invention. Such as Figure 9 As shown, each device is in the initial state, and the pusher 1 in the present embodiment has a first material storage device 61 and a second material storage device 62, and the first material storage device 61 and the second material storage device 62 are respectively loaded For different raw materials, the upper end surface 31 of the lower punch 3 is in the same plane as the plane 210 where the cavity entrance of the die 2 is located. Such as Figure 10 As shown, first calculate the distance s1 that the lower punch 3 moves downward relative to the plane 210 where the cavity entrance is located according to the quality of the first raw material that needs to be filled, that is, the quality of the first raw material is determined by the The upper end s...

Embodiment 3

[0039] Such as Figure 13-Figure 17 As shown, this embodiment takes the manufacture of a three-layer brush as an example to illustrate the press-forming method of the multi-layer brush of the present invention. Such as Figure 13 As shown, each device is in an initial state, and there are two pushers 1, and the first pusher 11 has a first storage device 61 and a second storage device 62, and the first storage device 61 and the second storage device The feeding device 62 is respectively loaded with different raw materials, the second pusher 12 is loaded with a kind of raw material, and the upper end surface 31 of the lower punch 3 is in the same plane as the plane 210 where the cavity entrance of the die 2 is located. Such as Figure 14 As shown, first, the distance s1 that the lower punch 3 needs to move downward relative to the plane 210 where the cavity entrance is located is calculated according to the mass of the first raw material that needs to be filled, that is, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com