Normalizing and back run biomass gas-carbon cogeneration producer and gas-carbon cogeneration method

A biomass gas and generator technology, which is used in biofuels, coke ovens, special forms of dry distillation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

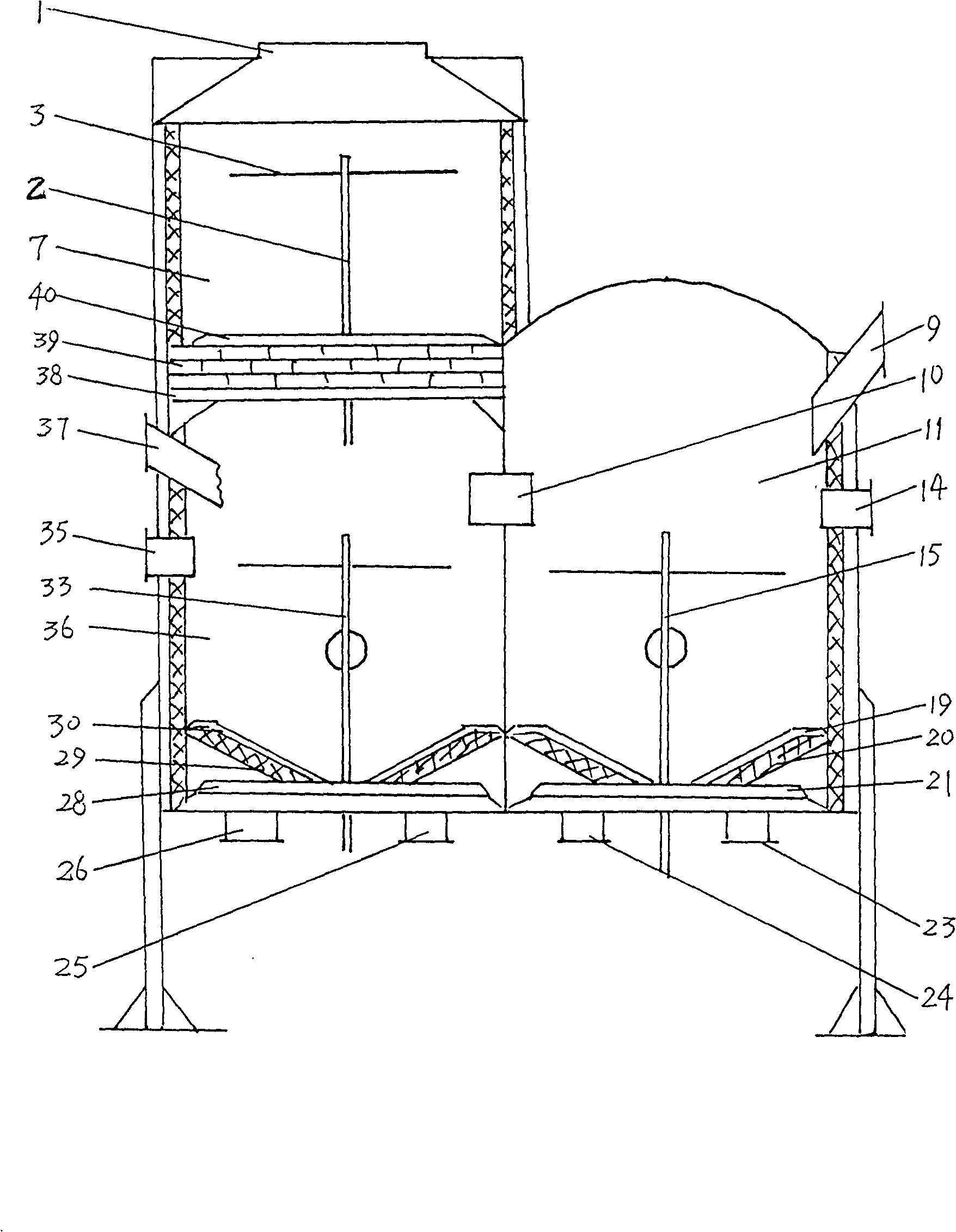

[0018] The forward-backfire biomass gas-char cogeneration generator of this embodiment is shown in FIG. 1 , the upper part of the gasifier is the reverse-fire gasification hearth 7 , and the lower part is the normal fire gasification hearth 36 . The top of the backfire gasification hearth is a backfire feed inlet 1 (also used as a backfire air inlet), and the bottom is connected with the normal fire gasification hearth through the backfire grate 39 . The anti-fire fire grate 39 is supported on its support 38, and the anti-fire fire rake 40 is placed above. The side wall of the normalizing gasification furnace is provided with a feeding port 37 and an explosion-proof port 35 , a normalizing furnace rake 30 is placed on the bottom normalizing grate 29 , and an ash outlet 26 and an air inlet 25 are provided under the lower ash scraper 28 . The carbonization chamber 11 is adjacent to the normalizing gasification furnace, and communicates with the normalizing gasification furnace t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com