Secondary lithium ionic cell positive electrode active material with Li*O 2B*O* coated on surface

A technology for positive electrode active materials and lithium-ion batteries, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of less research on positive electrode active materials for secondary lithium-ion batteries, and achieve a feasible preparation method, good effect, and good cycle performance Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] LiOH·H 2 O, H 3 BO 3Mix with the positive electrode material of the secondary lithium ion battery in a mass ratio of 5 to 10:14.6:1000, carry out ball milling on a planetary ball mill, put the mixture into a ceramic flat-bottomed bowl and carry out high temperature treatment, and the heat treatment atmosphere is a mixture of air or oxygen and air. Heating and heat preservation treatment, the heating rate is 5-20°C / h, the heat preservation range is 200-550°C, and the heat preservation time is 1-10h; The time is 1-15 hours; the ceramic flat-bottomed bowl containing the fully reacted compound is cooled at a rate of 10-20 / min. When it is lowered to room temperature, the compound in the ceramic flat-bottomed bowl is poured out and sieved to obtain 1% wt surface coated with Li 2 O·2B 2 o 3 Cathode material particles for secondary lithium ion batteries.

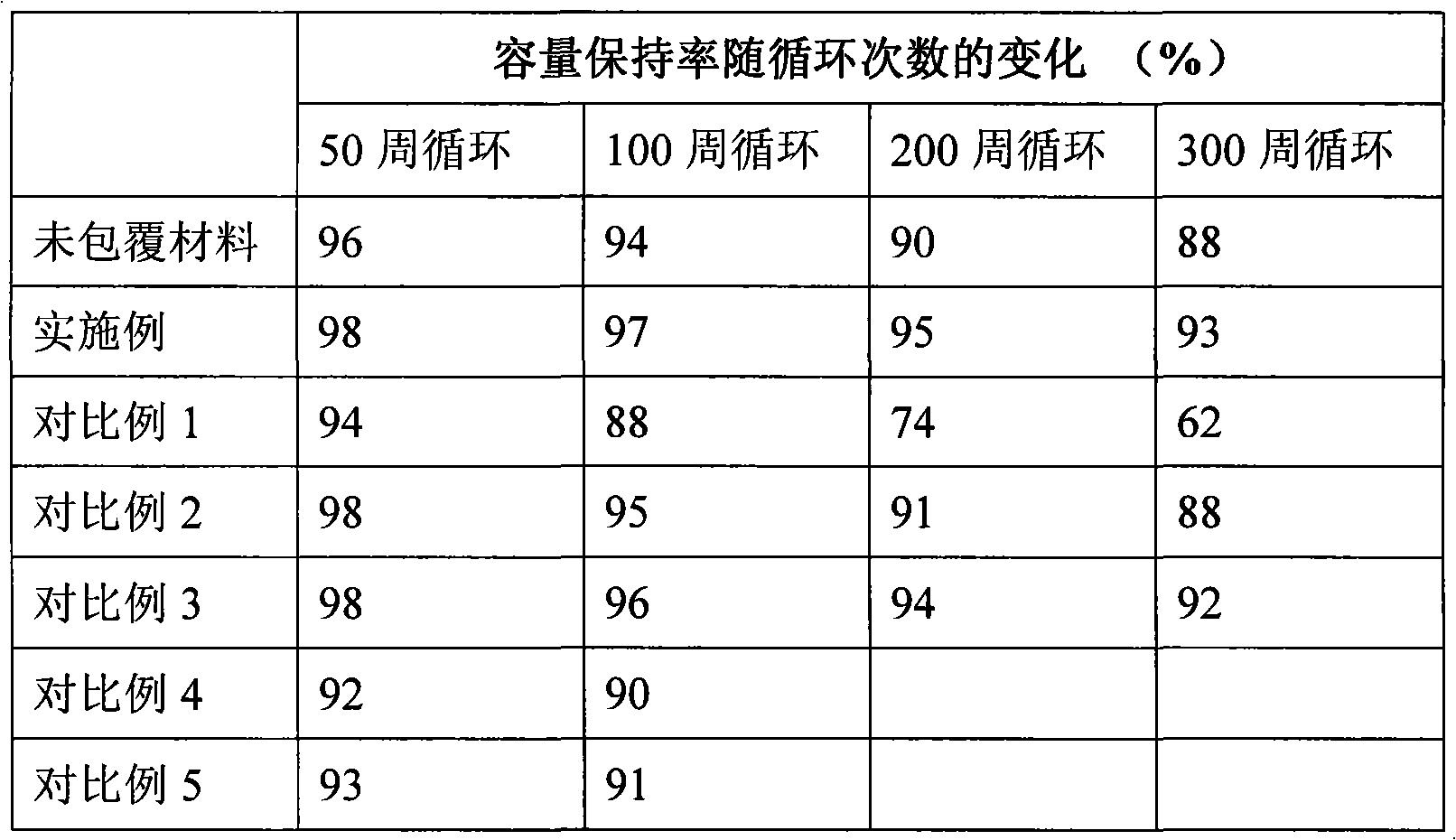

[0023] Surface coated Li in positive electrode materials 2 O·2B 2 o 3 The positive electrode active material, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com