Two-axis stubbling rotary-tillage fertiliser deep-placement adjustable repression sowing device

A dual-shaft, seeder technology, applied in fertilizers and seeding equipment, planting methods, agricultural machinery and implements, etc., can solve the problems of difficulty in simultaneously ensuring the quality of stubble cutting and soil preparation, difficulty in ensuring fertilizer efficiency, and small design row spacing, etc. Satisfy high-yield agronomic requirements, improve fertilizer utilization, and reduce trenching resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

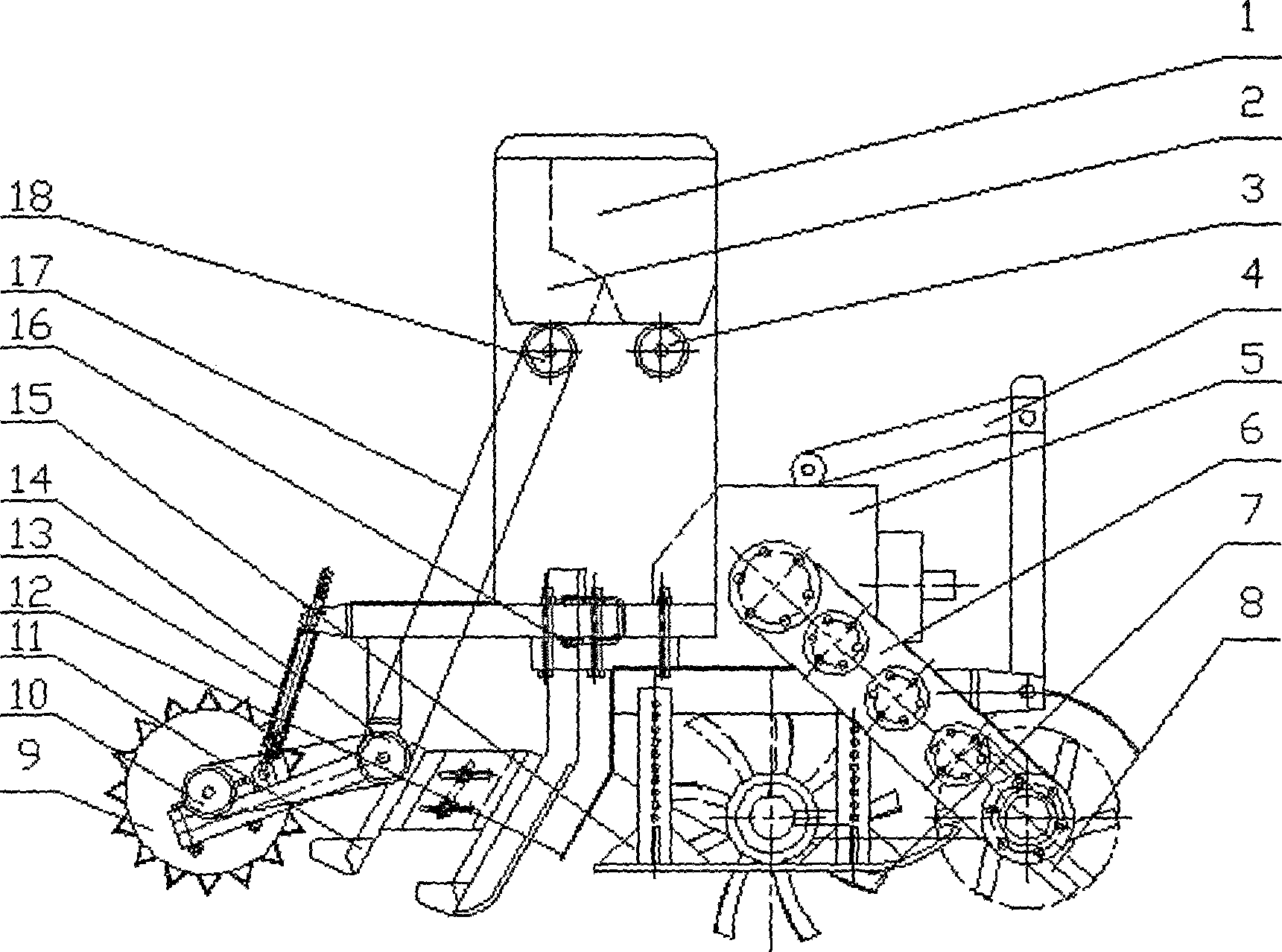

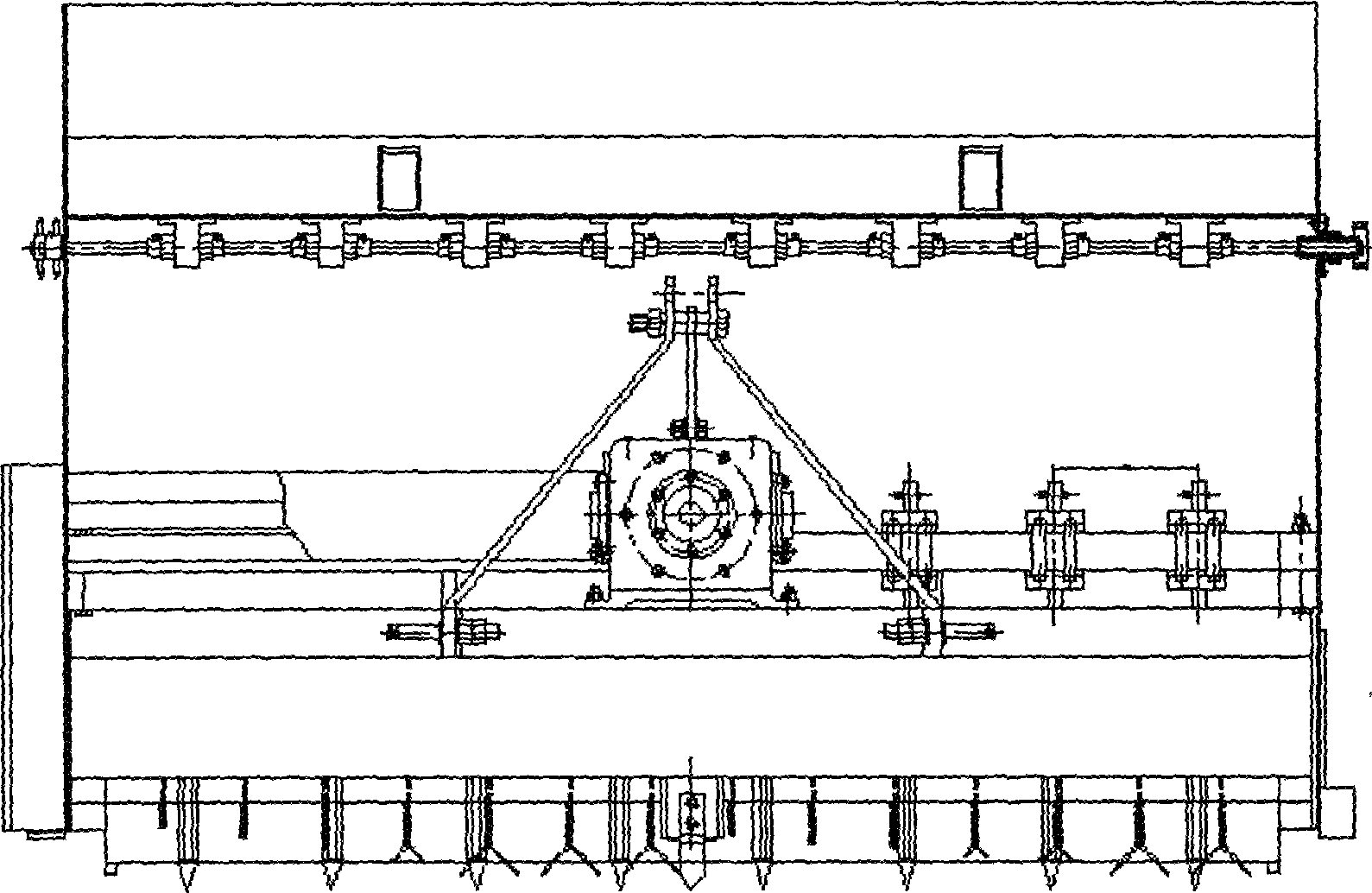

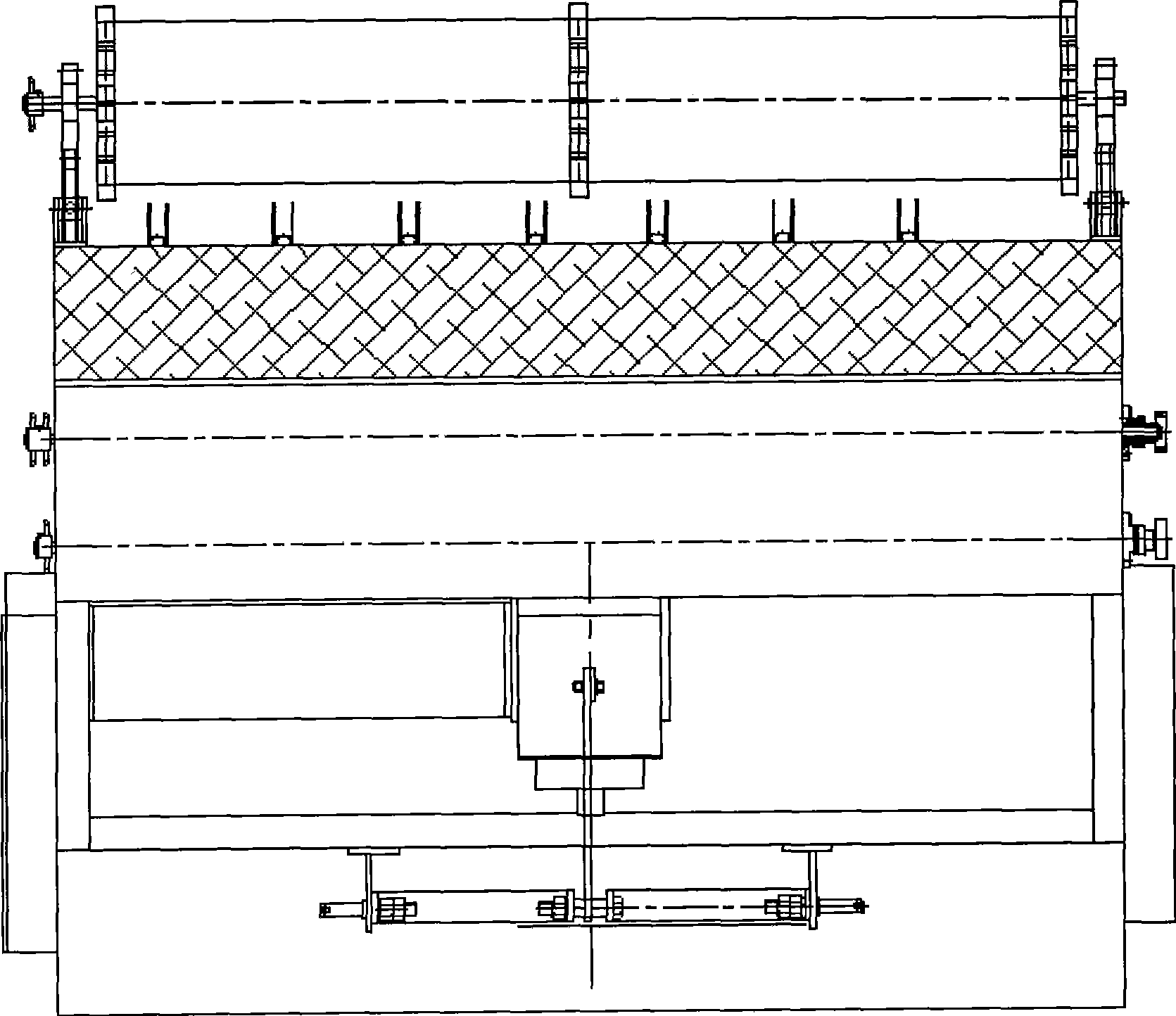

[0011] In the figure, the speed of the power output shaft of the tractor is 1000rpm, and it is connected with the input shaft of the main gearbox (5) through a universal joint. The other power output of the gearbox (5) is transmitted to the auxiliary gearbox (6) through the universal joint, the transmission ratio is 2:1, and the rotating speed of the stubble cutter is 500rpm; the ditch opener (11) is an adjustable seed fertilizer layer thickness The composite opener adopts a single-row structure, and its entry angle is 120°. The opener (11) is connected to the girder through the consolidation device (16). The sowing depth can be changed by changing the upper and lower positions of the opener (11) on the consolidation device (16); the pressing wheel (9) is of the integral floating adjustable pressure type, and the pressing force can be changed by changing the initial compression amount of the pressing wheel spring , the suppressing wheel (9) doubles as the ground wheel, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com