2-keto-d-gluconic acid continuous fermentation process

A technology of gluconic acid and glucose, applied in the directions of fermentation, microorganism-based methods, microorganisms, etc., can solve the problems of low fermentation yield, rising production cost, loss of production capacity of fermentation equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

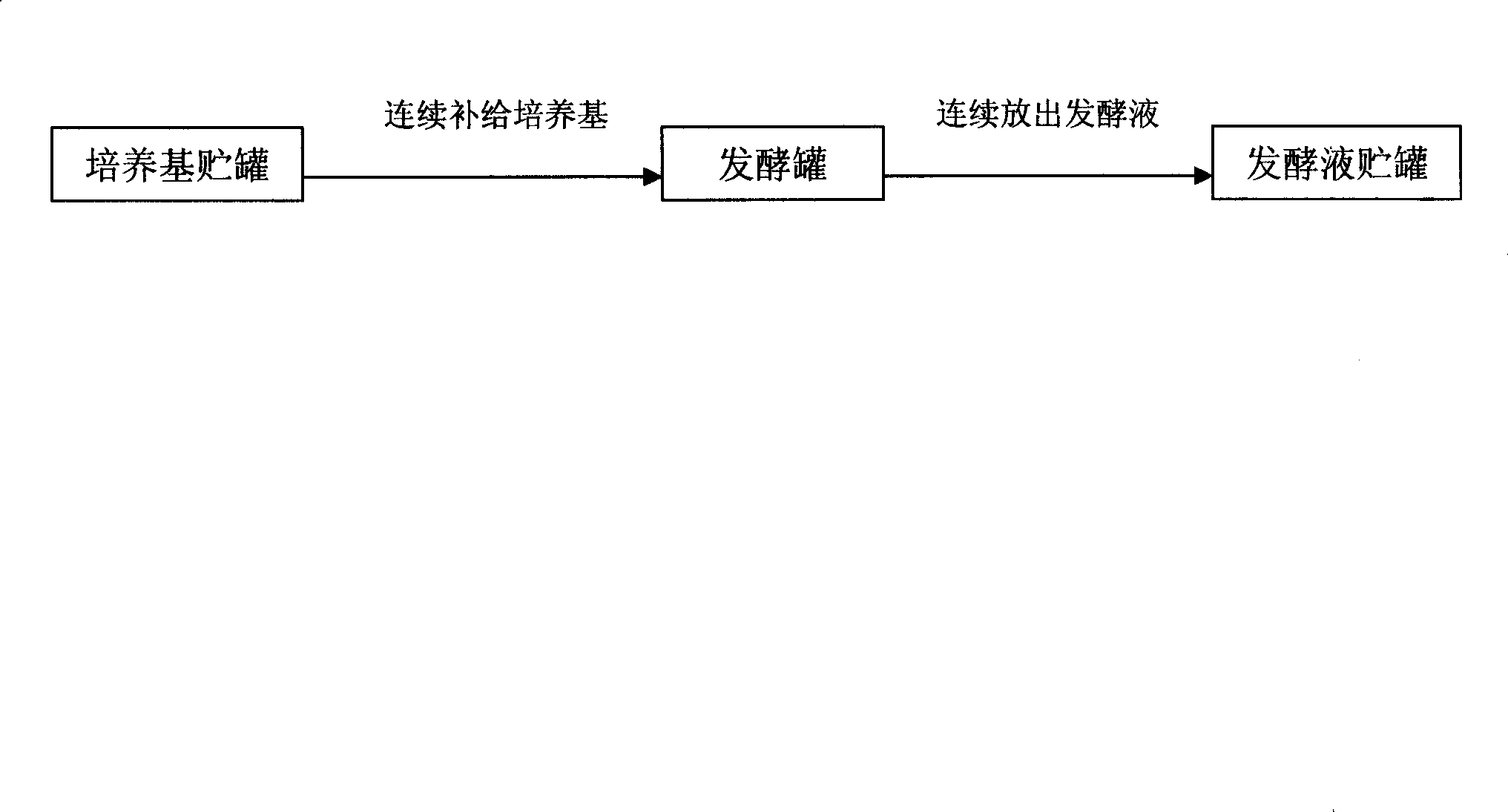

Image

Examples

Embodiment 1

[0021] In this embodiment, a 5L self-controlled fermenter was used for seed cultivation. Put the bacterial suspension of Pseudomonas fluorescens K1005 into 3.5L containing 2.0% glucose, 1.0% corn steep liquor, 0.2% urea, 0.2% KH 2 PO 4 , 0.05% MgSO 4 ·7H 2 O, 0.25% light CaCO 3 In the seed medium (pH 7.0 before sterilization), the stirring speed was controlled to 400 rpm, the tank temperature was 33° C., the tank pressure was 0.030 MPa, and the ventilation rate was 0.5 v / v / m for 20 h.

[0022] The continuous fermentation adopts a 50L self-controlled fermenter, which has a stirring system and a control and monitoring system for temperature, pH, and dissolved oxygen (DO). Its working volume is 35L, the temperature is controlled at 33±1°C, the stirring speed and ventilation rate are set at 400rpm and 3.5L / min, respectively. During the continuous fermentation process, use a peristaltic pump to control the feeding rate, and use another peristaltic pump to continuously discharg...

Embodiment 2

[0025] Seed culture and fermentation conditions are controlled with embodiment 1.

[0026] The composition of the fermentation medium was: 18.0% starch hydrolyzed sugar, 1.7% corn steep liquor and 5.0% light CaCO 3 (pH6.7 before sterilization). Put the cultivated seed liquid into 35L fermentation medium and cultivate for 30h, then switch to continuous fermentation mode, set the dilution rate to 0.055h -1 , Continuous feeding of fermentation medium at a feed rate of 1.925 L / h. Continuous fermentation was carried out for 120 hours in total, producing 45916.9g of 2-keto-D-gluconic acid, the concentration of 2-keto-D-gluconic acid in the fermentation broth was 173.6g / L, and the average residual glucose in the fermentation broth was 0.011% . Calculated according to the above results, the average fermentation conversion rate (mol / mol) is 88.98%, and the average fermentation yield is about 6.12g / L / h.

Embodiment 3

[0028] Seed culture and fermentation conditions are controlled with embodiment 1.

[0029] The composition of the fermentation medium is: 18.0% starch hydrolyzed sugar and 1.5% corn steep liquor (pH4.5 before sterilization, adjusted to 6.2 with sterile sodium hydroxide solution after sterilization). Put the cultured seed liquid into 35L fermentation medium for cultivation, and use sodium hydroxide solution to control the pH of the fermentation liquid to about 5.3, and switch to continuous fermentation mode after 30h, and set the dilution rate to 0.055h -1 , Continuous feeding of fermentation medium at a feed rate of 1.925 L / h. Continuous fermentation was carried out for 144 hours in total, producing 54072.8g of 2-keto-D-gluconic acid, the concentration of 2-keto-D-gluconic acid in the fermentation broth was 173.3g / L, and the average residual glucose in the fermentation broth was 0.009% . Calculated according to the above results, the average fermentation conversion rate (mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dilution degree | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com