Method for producing pyrroloquinoline quinine through microbial fermentation and fermentation medium used in same

A pyrroloquinoline quinone and microbial fermentation technology, applied in the field of microbial fermentation, can solve the problems of long production cycle of strains, low yield, restriction of synthesis regulation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1 The activation of methylotrophic bacteria Methylovorus sp.MP688

[0088] Methylovorus sp.MP688 is preserved in CGMCC4096 of China General Microorganism Culture Collection Center, and it is a strain whose PQQ production reaches the production level. Use the original strain (glycerol preservation or freeze-dried state) to streak on a solid medium plate, and culture it at 30°C for 2 days; pick a single colony, inoculate it into 5ml liquid medium, culture it at 30°C, shaker at 200 rpm, and cultivate it for 48 hours as activated seeds. The solid medium is to add agar powder and carbon source methanol on the basis of the basic medium, and the concentration of the agar powder in the fixed medium is 1g / L; Carbon source methanol is added on the basis; wherein the concentration of the methanol in the fixed medium or liquid medium is 10g / L; the components and proportioning of the basic medium are as follows:

[0089] Basic culture medium (in 1L)

[0090] MgSO 4 ·7...

Embodiment 2

[0104] The preparation of embodiment 2 seed liquid

[0105] Get 2ml of the bacterial solution obtained in Example 1, and inoculate it into a conical flask containing 100ml of liquid medium, at 30°C, on a shaker at 200 rpm, and cultivate for 36 hours, and activate it 1-2 times under the same conditions to make the final fine density ( OD 600 ) is 1.2 to 1.5, made into seed solution. The liquid medium used is the same as in Example 1.

Embodiment 3

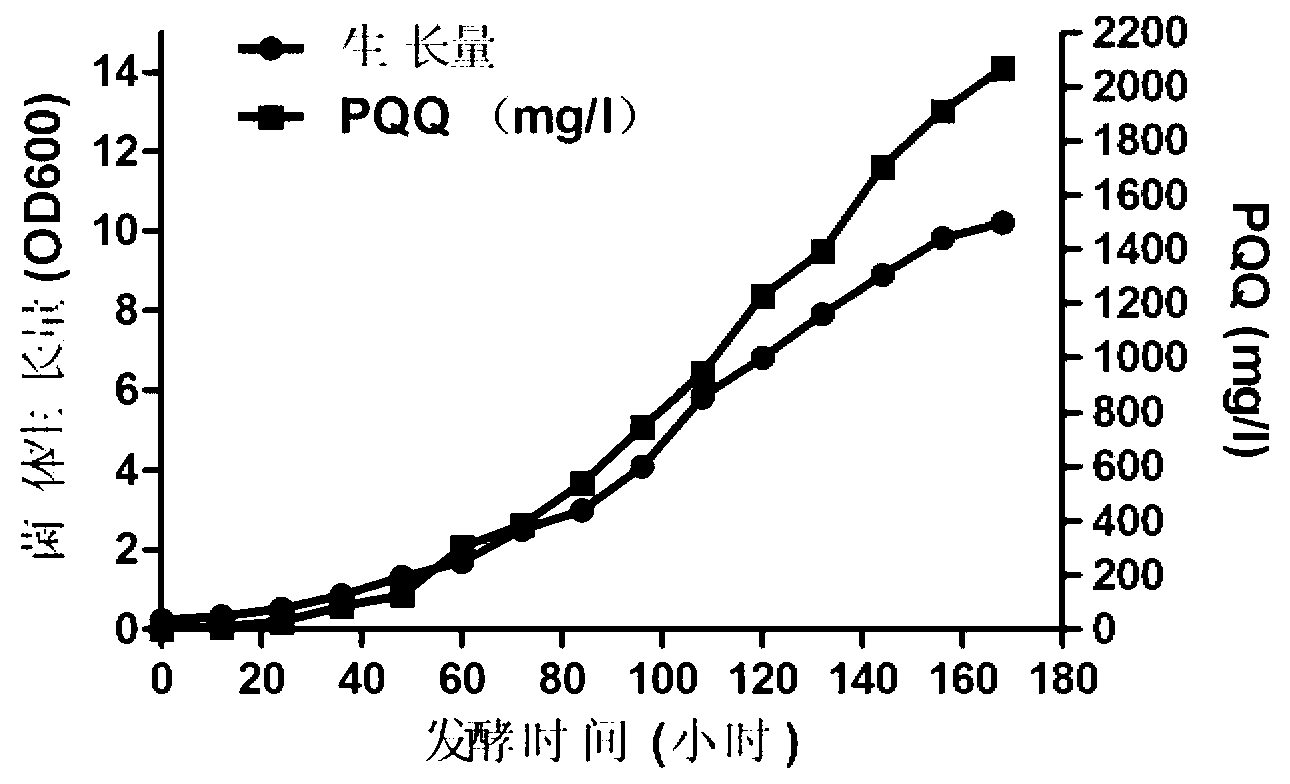

[0106] Embodiment 3 carries out PQQ production example A in 5L automatic fermenter

[0107] With the seed liquid of embodiment 2, inoculate in the 7.5L automatic fermenter according to the ratio of 1:20. After inoculation, the initial ventilation volume of the fermentation was controlled at 1vvm, the stirring speed was controlled at 300rpm, the temperature was controlled at 0°C, and the initial pH value was set at 7.0; the initial concentration of methanol as a carbon source was 7.5g / L, and the initial concentration of ammonium sulfate as a nitrogen source was 15g / L. L; described fermentation medium, concrete composition and proportioning are as follows:

[0108] Fermentation medium (according to 1L)

[0109] MgSO 4 ·7H 2 O 0.4g,

[0110] (NH 4 ) 2 SO 4 3g,

[0111] K H 2 PO 4 2.8g,

[0112] Na 2 HPO 4 12H 2 O 6g,

[0113] Ferric Citrate 60mg,

[0114] CaCl 2 0.05mg,

[0115] MnCl 2 4H 2 O 5mg,

[0116] ZnSO 4 ·7H 2 O 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com