Technique for coating inorganic strengthening layer on polyphenyl thioether fabric surface

A technology of polyphenylene sulfide fiber and process method, which is applied in the directions of fiber processing, fiber type, textile and paper making, etc., can solve the problems of reduced mechanical properties and unchanged mechanical properties of polyphenylene sulfide fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

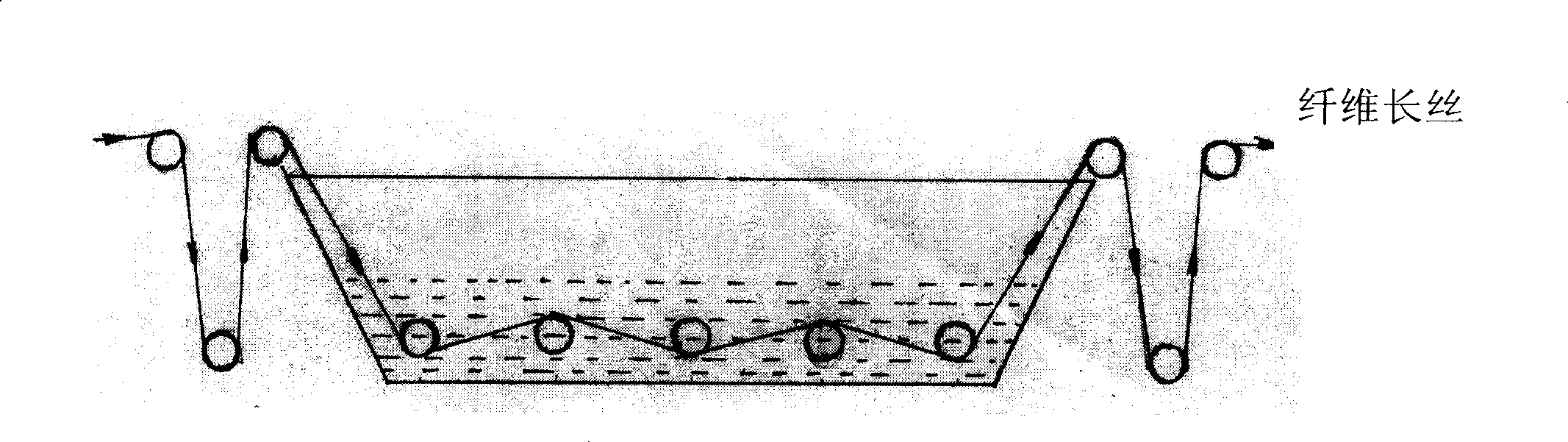

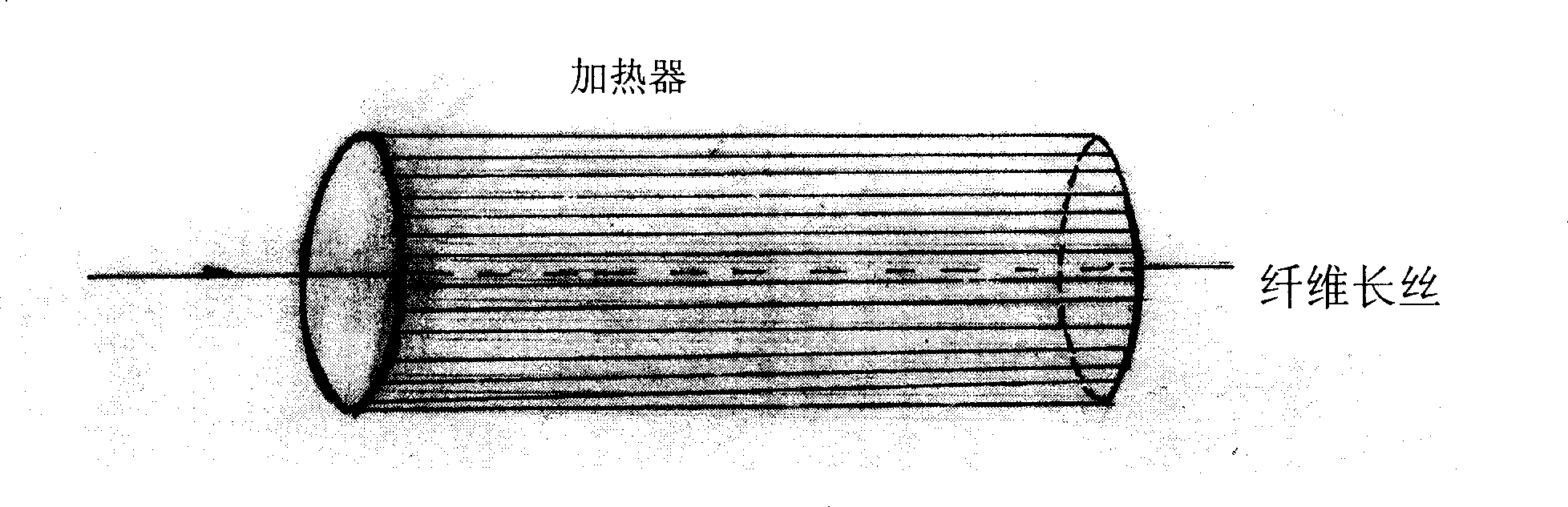

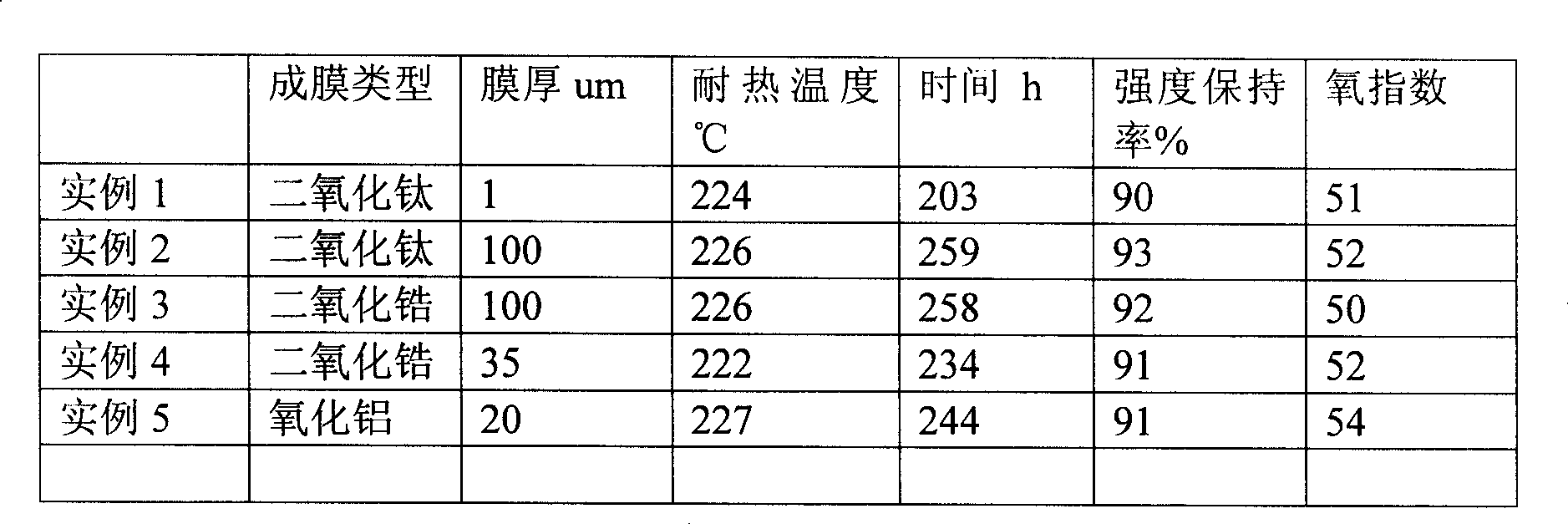

[0023] Use an isopropanol solution with a titanium lactate content of 3.5%wt, using the attached figure 1 The impregnation process is impregnated for 15 minutes, first dried by air at 20°C, and then transported into a cylindrical electric heating furnace at 600°C for heat treatment for 15 seconds (s), so that the polyphenylene sulfide fiber is coated with a layer of titanium dioxide film, so The structure and properties of polyphenylene sulfide before and after smearing treatment are shown in the attached image 3 indicated in the table.

Embodiment 2

[0025] Use the isopropanol solution whose triethanolamine titanium content is 0.5%wt, adopt the attached figure 1 The impregnation process is impregnated for 120min, first dried by air at 20°C, and then heat-treated for 12s in a cylindrical electric heating furnace at 620°C after being conveyed, so that the polyphenylene sulfide fiber is coated with a layer of titanium dioxide film. The structure and properties of phenylene sulfide are in the attached image 3 indicated in the table.

Embodiment 3

[0027] Use the isopropanol solution with zirconium butoxylate content of 3.5%wt, adopt figure 1 The impregnation process is impregnated for 15 minutes, first dried by air at 20°C, and then transported into a cylindrical electric heating furnace at 685°C for heat treatment for 10s, so that the polyphenylene sulfide fiber is coated with a layer of zirconium dioxide film, so the coating treatment The structure and properties of polyphenylene sulfide before and after are in the attached image 3 indicated in the table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com